A day trip to the shore, a hike among abandoned buildings, a rock show, and more.

(Continued from Part 3: In Washington DC)

My brother had to work on Saturday. He does that sometimes just to catch up when there’s no one in the office. I have vague memories of working in an office environment every day and know how distracting it can be. Meetings, phone calls, co-workers coming in to chat, long lunch breaks. I honestly don’t know how people in an office can get much done.

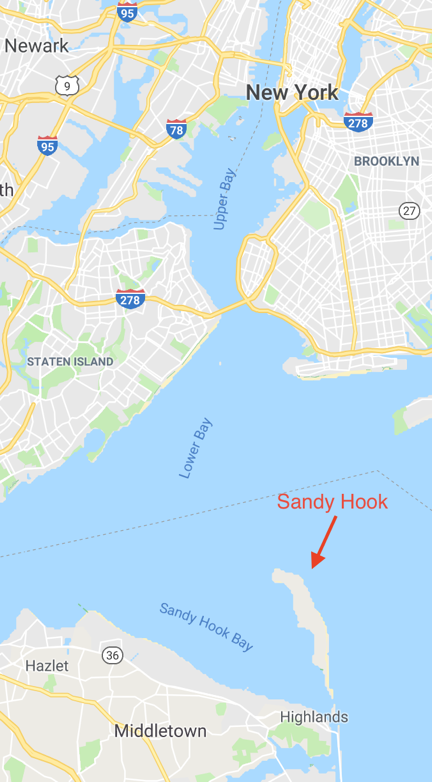

He took his truck to work and left me the keys for the Maserati. He was gone when I woke up around 5 AM. I washed up, got dressed, grabbed Penny and my camera, and headed out. My destination was Sandy Hook on the north end of the Jersey Shore. (And no, this Sandy Hook isn’t the one famous for the tragic school shooting. That’s in Connecticut.)

Breakfast at Dunkin Donuts

But first, breakfast. My brother had been telling me about these breakfast wraps he gets at Dunkin Donuts. We don’t have Dunkin Donuts in Washington state — at least I haven’t seen any — and since I used to like their coffee, I used Google to find one on the way. The one I went to was in a small strip mall not far from the Garden State Parkway. I went in, stood on a fast-moving line, and ordered a coffee with one of those wraps.

“How do you want the coffee?” the no-nonsense woman behind the counter asked me.

I had completely forgotten that they add milk and sugar to your coffee behind the counter in a lot of places in the New York City area. I looked around quickly; there was no milk or sugar out for me to add myself. This was a dilemma for me. My morning coffee is important to me and I like it a certain way. I knew they’d screw it up. I looked up at the woman and could see that my hesitation was trying her patience. This was the Metro area and I was slowing things down.

“A small amount of sugar and milk,” I told her.

I paid and got my coffee. They called me up to get my breakfast wrap a moment later. I sat at a hightop table to eat my breakfast. Although they’d done okay with the quantity of milk and sugar, the coffee was terribly weak. I forced myself to drink it, knowing I’d have a headache from caffeine withdrawal in two hours if I didn’t. The breakfast wrap was tasty but tiny. I could have eaten three of them.

A Visit to Sandy Hook

As I walked back to the car, a woman getting out of the car next to me said, “I love your car! I’m trying to get my husband to buy me one of those.”

I thought to myself: A Maserati? She must have a very generous husband. Out loud, I said, “It’s my brother’s. He’s loaning it to me.”

“You have a great brother!” she replied, laughing.

The Garden State ParkwayI need to talk briefly about the Garden State Parkway in New Jersey. (You might know it as part of an old Joe Piscopo joke on Saturday Night Live: “I’m from Joisey? You from Joisey? What exit?”) It stretches from the New York State border in the north to Cape May at the southern tip of the state. I drove part of it every day in my last office job. What I didn’t realize then and know now is that it’s basically a racetrack.

You see, even though the speed limit is posted 55 or 60 in various places and I cruised at around 70 to 75, people were passing me. Not just a few people, either. Most of the other drivers. Apparently, the speed limit signs are suggestions and most people are in a big hurry. I didn’t realize this when I was one of those drivers.

The good thing about the situation is that the New Jersey drivers ignoring the speed limit signs are mostly great drivers. They probably drive a lot of miles and they likely have a lot of experience with the terrible drivers putting on the road with them. Driving on the Parkway reminded me of my commuting days when I felt as if I were in a sport boat speeding down a river and the slower cars were boulders in rapids that I had to avoid hitting. I was an expert at weaving between them without making a single one of them hit their brakes. (It’s a matter of looking far enough ahead and seeing the big picture of the flow.) It had been a very long time since I drove like that, but it came back quickly — as long as the pavement was dry. Later in my trip, after it rained, I took it easy, not wanting to test the new tires my brother had put on the car when I went to Washington. The car was perfect for the aggressive driving style popular in the New York City Metro area and, when I dialed in, I really enjoyed it.

I gave Penny some of the bacon and egg I’d saved from my breakfast wrap, and headed out of the parking lot. A short while later, we were driving south on the Garden State Parkway, headed for the Jersey Shore.

The drive way uneventful. The Parkway doesn’t pass through any really scenic places along the way. My brother had an E-ZPass on the car — yes, not only did he loan me his car, but he also paid my tolls — so I didn’t have to stop any any of those super annoying tollbooths along the way. I got off at the exit for Keyport and followed route 36 through some of the northern shore towns I’d never visited in all the years I’d lived in New Jersey: Hazlet, Keansburg, Atlantic Highlands, Highlands. Then the road climbed over a high bridge over a waterway. At the top, my first look in many years of the sparkling blue Atlantic Ocean took my breath away.

Even though I’d never lived on the Jersey Shore, I felt as if I’d come home.

I followed signs to Sandy Hook, which put me on a northbound road. There was a fee booth — Sandy Hook is part of the Gateway National Recreation Area, after all — but it was unoccupied and there way no fee. Back east, “the season” ends on Labor Day in so many places.

I pulled into the first beach access parking lot and got out. Signs reminded me that dogs had to be on a leash so I dutifully hooked up Penny’s and walked her out on path to a wooden observation deck and then down onto a sandy path that cut through the dunes. Out on the beach, a handful of people were walking or jogging or fishing or flying enormous kites.

The scene at the beach at Sandy Hook that fine September day.

Penny strained at her leash; she loves the beach and doesn’t like being on a leash when she wants to run. I didn’t want to get cited for letting her off-leash, so I waited until we were almost all the way down to the water to let her go. She ran south along the water’s edge, chasing seagulls, while I walked behind her. It was too cool to take off my shoes and socks, but warm enough to really feel comfortable. Although I’m not much of a swimmer and I hate sunbathing, I really do like the seashore.

Sandy Hook has a strategic location on the approach to New York City — which is why there are so many battlement remains and an active Coast Guard base there.

I let Penny run away, then called her back, then let her run away again. I wanted to tire her out a bit. This would likely be the only opportunity all day for her to be off leash. I think that’s the worst thing about traveling with her. She isn’t used to being on a leash and, when we’re in an open place like that, she doesn’t understand why she has to be on one. I don’t, either. If she doesn’t bother people or animals or destroy anything and I pick up after her when she poops, what difference does it make if she’s on a leash or off it? We were two specks on a miles long stretch of sand with only maybe a dozen people nearby. What was the big deal?

I put her back on the leash and walked back to the car. We continued on the road, looking for some sort of visitor center where I could plan my visit a little better. We wound up at the Sandy Hook Lighthouse a few miles away.

The lighthouse at Sandy Hook.

There was a visitor center there and I went in for a look. There were a few typical light house displays, but also a neat map that showed the locations of all the light houses that had been in the area over time. You could dial up a year and lights would indicate which lighthouses existed at the time and were functioning. Sandy Hook is at the south end of the entrance to New York’s Lower Bay and apparently it’s a crucial point for navigation, with lots of shallow water and obstacles in the mouth of the bay.

I went into the gift shop where a ranger sat at the counter. We talked a bit about off-season travel and the popularity of the area for birders. Then I went outside where I’d left Penny tied to a tree. There was a group of boy scouts in their teens, along with a few adults and a ranger at the base of the light house. I managed to wrangle myself a trip to the top of the lighthouse with the group. They were just waiting for the previous group to come down.

I went up last on the climb up a narrow spiral staircase to the top of the lighthouse, right behind a guy of about 16 years old who had to weigh at least 250 pounds. At the top landing was a ladder that we’d have to climb though a hatch. The big kid let me go first, which I appreciated; I honestly didn’t know if he’d fit through the hatch. Upstairs, the space around the fresnel lens was tightly packed with people. It got a little tighter when the big kid joined us.

A look down the spiral staircase from near the top (left) and the ladder to get up to the top of the lighthouse (right).

The views in every direction were amazing. It was a relatively clear day and we could see Manhattan’s skyscrapers to the north, as well as the endless expanse of the Atlantic Ocean, New Jersey, and the shoreline to the east, west, and south.

You can see the Verrazzano Narrows Bridge on the left and the downtown Manhattan skyline on the right through the haze on the horizon in this photo. In the foreground, you can see the ruins of the various batteries built and abandoned over time.

We didn’t stay long. I was one of the first back through the hatch — mostly because it was so tight up there that no one could easily get around me — but the last down the stairs. Afterwards, I fetched Penny from her tree and we took a walk among some nearby ruins. I love photographing old, disused things and this place was full of them. Unfortunately, so many areas were blocked off — as is common in the eastern part of the country. (Out west, they let you go pretty much anywhere you want but in the east, they’re constantly fencing things off to supposedly prevent people from getting hurt.)

I like taking photos of old things, especially if they’re rusty. Why knows why?

Eventually, we went back to the car and drove to the end of the peninsula. There was apparently some sort of major Boy Scout camping event going on — tents with flags for various troops filled one of the parking lots. We walked out to an observation deck that looked out over some marshy lands, a beach, and the ocean and lower bay beyond. There were two rangers on the deck and several men with binoculars and spotting scopes. They were looking for birds. One of them claimed to have Shoreham Power Plant focused in his spotting scope and I accepted his invitation to take a look. Back in 1977, my family moved to Long Island so my stepdad could work on the construction of the Shoreham nuclear plant. I saw the smokestacks in the spotting scope, but I’m not convinced that was Shoreham, which was on the north shore of Long Island at least 100 miles away.

The view from the observation platform which was about one story above the dunes.

We hung out for a while, listening to the guys talk and get excited when they saw a bird. Huge tankers passed remarkably close to the beach; later, when I looked at a nautical chart of the area, I saw that the channel was right there with lots of shallow water between it and lower Manhattan in the distance. One of the men seemed knowledgable about marine navigation in the area and I asked him a few questions about the easiest way to get from the ocean into New York Harbor: a channel under the Verrazzano-Narrows Bridge or up the west side of Staten Island. He didn’t know. I hope to find out for myself one day.

We walked back toward the car and then beyond it to the remains of a big 9-Gun Battery from World War II. I’d seen lots of old batteries like this on the west coast — most recently on a trip out to the coast of Washington that I never blogged about — but this was my first in the New York area. It was a huge poured concrete structure with lots of rusting metal doors and rails and you can bet I took lots of photos of various parts of it — even though a fence kept me from getting close. I guess they wouldn’t want tourists climbing all over the ruins (like they can out west).

Here’s a very small part of the 9 Gun Battery at Sandy Hook.

Lunch at Sea Bright

After our walk, we went back to the car. I drove past some of the old housing on the west side of the peninsula in an area called Fort Hancock. Then we drove south off Sandy Hook in search of lunch. The weather was perfect and I was hoping to find a place with outdoor dining where I could take Penny. After pulling into a place with valet parking and deciding I didn’t want to turn over my brother’s car to a valet — remember that scene in Ferris Beuller’s Day Off? — I eventually found a parking spot at Tommy’s Tavern + Tap, a sports bar with a big family outdoor dining area. I carried Penny through, ordered a Bloody Mary and a clam pizza (don’t knock it until you’ve tried it), and settled down to enjoy my meal.

Penny waits for pizza. She ate nearly a whole slice.

One highlight: two women with a kid in a stroller and another kid about 4 years old walked by. The 4-year-old wanted to pet Penny but didn’t ask me or her mother if she could. The mother didn’t ask me, either. Maybe they were waiting for me to offer? I’m not going to offer to let a small kid touch my dog — what if she has allergies or scares Penny into yapping at her? It’s their job to ask me. But they kept walking by and then the kid started screaming because she couldn’t pet the dog. She kept at it for about 10 minutes. It was seriously annoying to everyone on that patio.

Meanwhile, Penny waited patiently until I shared my pizza with her.

We strolled down one side of the street in Sea Bright, looking into shop windows. Several stores had closed down. Remember, the season was over; I’m willing to bet that many businesses on the Jersey Shore get short term leases and close right after Labor Day. We crossed over and followed a path to a big board walk on a new embankment along the ocean. It looked brand new. I suspect the area had been pretty badly ravaged by Superstorm Sandy; there were a few homes under reconstruction on the land side of the walkway. There weren’t many people on the beach and I honestly didn’t feel like taking another walk there with Penny straining at the leash the whole way. So when we were abeam the restaurant, we followed a path off the boardwalk and returned to the car.

Back to Base

I made a few stops on the way back to my brother’s place.

First, an auto parts store. I wanted to get a cell phone holder for his car. He’s got a magnetic thing in there that works with his phone case. I wanted something that would stand the phone up. I wound up with one of those cell phone holders that sits in a cup holder. It worked a lot better than I expected it to. I was going to leave it for him but wound up taking it home and will likely use it in my truck since my new phone doesn’t fit quite as well as the suction cup mount I have.

Next, a Maserati dealer, to try to get the battery replaced in the key fob. There’s a long story about the key fob but it really isn’t worth telling. Let’s just say that the trip to the dealer was a huge waste of time.

Finally, Wegman’s. That’s a chain of premium grocery stores. Think of Whole Foods but without the attitude. (Although now that Amazon owns Whole Foods, the attitude might be gone; I don’t know.) I had the idea of buying something for dinner. But when I got my brother on the phone, he wanted to go out for Mexican. So I satisfied myself with buying some car snacks for the next day and headed back to his place.

We went to a Mexican restaurant that he likes and had a good meal. Then we hung out at his place until it was time for bed.

Heading Out on My Road Trip

In the morning, I got up at the same crazy early hour as my brother. He was going to a match in Pennsylvania that day — did I mention that he’s a competitive shooter? — and needed an early start. We chatted for a while before he left. Then he headed out and I prepped for my big road trip to Vermont.

But I wasn’t going straight to Vermont. Instead, I planned to spend the day in northwestern New Jersey. I figured I’d start with a hike at Watchung State Park, then hit a rock show in Franklin, and spend the night somewhere near Port Jervis where New York, New Jersey, and Pennsylvania meet.

I planned to bring all of my luggage. I had no idea what the conditions would be where I was going and I didn’t want to run out of clothes. I also wanted to spend some time organizing my luggage and shipping back some heavy things I bought before I headed home. Besides, did my brother really need my giant suitcase on his floor any longer?

It took three trips to get everything out to his car. Then, with Penny on her blanket on the seat beside me, I asked Google Maps to guide me to a coffee shop in Westfield and took off.

Watchung Reservation

I had coffee and an egg sandwich at Rock ‘n’ Joe. Although it was a bit chilly, I ate it at a high top table outside with Penny at my feet. Westfield was a completely different town at the same time of day I’d been there the previous week.

I let Google Maps guide me to the Watchung Reservation, a large park with miles of wooded trails. My brother had suggested it as a destination; he and his ex-wife used to take their dogs there. I wanted Penny to get some quality off-leash time and I wanted to go for a nice walk in the woods. But I didn’t know where to start my visit. I figured I’d wing it, as I so often do.

In the end, I let signs guide me. Once I got into the lush, green park, I started seeing signs pointing to various areas within the park. One of them directed to a “Deserted Village.” Since I’m always up for a walk through a ghost town, that’s where I headed.

I parked among about 20 other cars in a parking lot, but rather than head down the paved road to the deserted village, Penny and I struck off on a nice trail into the woods. I let her off her leash almost immediately and she ran off in front of me as she usually does, stopping occasionally at the base of a tree when she saw a squirrel up above. We don’t have squirrels where I live — not many trees and plenty of predators like eagles and owls — so it’s always a treat for Penny to go for a hike in the woods where squirrels are plentiful. I’ve been with her at campsites in the north cascades where she’s parked herself at the base of a fir tree for a half hour or more just waiting for a squirrel to come down.

I used an app on my phone to keep track of my path so I wouldn’t get lost. The trail had side paths and I chose them almost randomly with a goal of not straying too far from the parking area and getting closer to the deserted village. One trail I took was narrow and wound down a little hill before heading back toward where I imagined the deserted village might be. I only passed one other hiker: a woman walking alone in the opposite direction. We greeted each other and kept walking.

The sole remaining original gravestone in this tiny burial ground.

Eventually, I wound up at a tiny cemetery. There was just one old gravestone still standing — it marked the grave of a man who’d died in 1776. I don’t know if I mentioned this elsewhere in this series of posts, but there are plenty of Revolutionary War error buildings and other sites. This was one of them. There were five headstones there, four of which were installed in the 1960s to replace missing ones.

Across a stream and up an embankment I could see some buildings, so that’s where we headed, crossing a bridge and climbing a path. I put Penny back on her leash, not wanting to get into trouble with any park rangers. We wound up on the Main Street of what was left of Feltville, which had been built starting in 1844 as a mill town, and Glenside Park, which had converted that mill town into a summer resort in 1882. There were a lot of old buildings, many of which were boarded up. There were also a lot of foundations, including that of the mill, which had been torn down in 1930.

We followed the roads and paths all over town to take in the various sights. There weren’t many people around on that pleasant Saturday morning; maybe because it was still early? Back down at the creek, I let Penny back off her leash while explored the mill site and a dam site. I took some pictures.

One of the buildings still in use a the Deserted Village. I was still getting use to my iPhone’s wide angle camera and didn’t expect this kind of distortion; I know now that putting it in 2x mode will prevent weird angles like this.

The dam site along the creek. You can just make out the berms on either side. This dam held back a small lake that channeled water to the mill downstream.

The obligatory mushroom photo(s). I played a little with the iPhone’s improved Portrait Mode in the photo on right. See how the background is out of focus? I think the mushrooms are a little out of focus because I was too close to them.

We were there about two hours and I only walked about 2 miles. But I was done and ready to move on. So I put Penny back on her leash and followed the paved road back up to the parking lot.

The Rock Show

I make jewelry out of gemstones. It’s a hobby gone wild that began with a lapidary in Quartzsite, AZ gifting me a small piece of bacon agate in January. I’ve since learned to use sterling silver and copper wire to create pendants and have branched off to making bracelets and earrings and even polishing my own stones. I now sell my jewelry online and at various venues in Washington and beyond.

The question I get most often from people who see my work and my sizable collection of gemstone cabochons — I have about 200 of these polished stones — is “Where do you get your stones?” My response, which tells only part of the tale without actually lying, is “I go to rock shows.” So when a chat with a gemstone dealer in Westfield the previous Saturday morning included him telling me about a rock show in Franklin, NJ that weekend, I put it on my list of things to do.

Franklinite in a sterling silver pendant.

Franklin, by the way, is where you can find Franklinite, a minor ore of zinc, manganese, and iron that was discovered at two mines in the Franklin area. I have a Franklinite cabochon that I used in a piece of jewelry (which is still available as I type this). The Franklin Mineral Museum has been hosting the Franklin-Sterling Gem & Mineral Show for 62 years. It was held in the Littell Community Center in Franklin, NJ. I learned what I needed to know to find it by working Google after talking to that rock dealer in Westfield. (Seriously: how did we survive before Google?)

Google Maps guided me there. I paid a $7 fee, got a wrist band, and drove into the parking lot. Since part of the show was outdoors, I put Penny on her leash and we walked from one outdoor vendor booth to the next. There were a lot of rocks, but not much of what I was looking for: affordable, interesting cabochons and slabs that I could cut and polish into cabochons at home. I bought a few small, cheap pieces: a pair of matched ammonites that I’ll make into separate pendants, a few polished agate slices, and some heart-shaped beads for earrings. Then I put Penny in the car and went inside.

(I should note here that when Penny is in the car, I can’t lock it; the alarm system in the Maserati is so freaking sensitive that a 7-pound dog moving around in there sets off the alarm and there doesn’t seem to be a way to lock the doors without turning on the alarm. So any time I left Penny in the car, the doors were unlocked. That’s normal for back home when I’m driving a 19-year old Jeep but not normal in the NYC metro area when I’m driving an exotic sedan.)

Inside was more of the same, although most of what was there was nicer. There was one booth with some incredible cabochons, but they were very expensive. My artist friend Janet says I need to buy good stones to sell my jewelry, but I know my local market. I can’t spend $50 on a stone when most of my local market balks at paying more than $49 for a pendant. The only pendants I can sell for more are the ones with popular, well-known stones like malachite and turquoise, and even then it’s tough to get more than $69. I’m hoping that if I sell at shows in Arizona this winter I can find a market with deeper pockets.

I did find some large cabochon beads with holes right down the middle. I’ve been using these to make “budget pendants” and, for a while, they were selling really well. I also found some small, inexpensive rose quartz cabochons. I chatted for a while with a dealer who goes to Quartzsite and Tucson every year; I’m wondering if I’ll find him down there in January.

Back outside, I made a conscious effort to find the rock dealer I’d spoken to in Westfield. I’d walked right past his booth on my first pass. We chatted for a while and he remembered me kind of vaguely. I noticed that he had a nice big labradorite slab with really nice blue highlights. He made me a deal on it and, although it’s a bit more than I wanted to spend, I know I’ll get at least a dozen cabochons out of it so it will definitely pay for itself with dividends. There’s even a chance that I might sell part of it for what I paid for the whole thing — I’m thinking about selling some of the slabs I’ve accumulated lately.

I should mention here that I do sell the cabochons that I buy. Although I began by showing them off at my day table as a way to interest customers in custom pendants — buy a stone and pay an extra $30 to have it made into a pendant in two hours — I’ve been selling quite a few stones to other jewelry makers and people who just like stones. The other day, in fact, a woman bought five stones, spending over $100. Although I make more money when I sell the stone in a pendant, I have a markup on the stones and selling them loose is a lot quicker and easier than making a pendant so I’m not complaining.

In all, I spent about an hour and $50 at the show, not including that $7 entrance fee. It was a nice little show, with “little” being the important word. When I go to Arizona in the winter, I see a thousand times more gems and minerals at just one of the venues. Prices are much better, too. I’m spoiled.

High Point

From there, we headed out towards Port Jervis. I had it in my head that I wanted to see High Point, so that’s what I asked Google Maps to guide me to.

Along the way, I stopped at a funky little restaurant in Sussex, NJ called the Sussex Inn Restaurant. It was on the lower level of a hotel. I sat in a booth and had a calzone (of all things). In one of the booths behind me was a very loud (and apparently old) British couple talking about the war — yes, World War II — and another equally loud Trump supporter. The calzone was huge and I wound up taking it with me but later throwing it away.

A wide angle view up the High Point Monument from its base.

On the way out of the park, I stopped for a more artistic shot of the Monument. I really am a sucker for reflections.

At High Point State Park, I followed the signs to get into the park. High Point gets its name because it’s the highest point in the State of New Jersey — a whopping 1600 feet above sea level. The entrance fee booth was closed — remember, it was after Labor Day — but there were plenty of people in the park. I followed the road up to the High Point Monument, a 220-foot tall obelisk built in 1928-1930 to honor veterans. I parked, put Penny on a leash, and got out for a walk. We went to the base of the monument, stepped inside but didn’t climb to the top, and took a hike in the woods. I got some nice views, especially out to the west where the Delaware River separated New Jersey from neighboring Pennsylvania.

A Night in Port Jervis

We didn’t stay long. After our hike, I worked Google Maps a bit to find a place to spend the night. Traveling with Penny is a bit of a challenge sometimes; many places don’t allow dogs. I found the Erie Hotel and Restaurant in Port Jervis and gave them a call. Apparently, the only phone was at the bar and it took a while for the bartender to find a manager who would say whether dogs were allowed. I finally got the green light and a rate and told them I’d be there within an hour.

It took considerably less than an hour to get there. Along the way, I stopped for gas and some dog food. I had a cooler with me — I’d bought some Italian pastries for my friends in Westfield that morning — so I bought some orange juice and yogurt, too. I was hoping to get some dry ice, but the supermarket didn’t sell it.

The hotel was one of those old railroad hotels built in 1890. Restored in 1994 after a fire, it still had the small rooms it might have had when built, although each room also had a bathroom which I doubt it had when first built. It was comfortable and quiet and cheap enough. I had a light dinner and a cold hard cider in the restaurant downstairs, which seemed to allow gambling via a keno-like game. After dinner, I fetched a bucket of ice and put it into the cooler to keep those pastries and other items cold. Then I took a quick walk up and down the main street in town — which was pretty dead on a Sunday night — and went up to my room with Penny.

We were asleep before 10.

(Continued in Part 5: On the Road to Vermont)