A quick overview of my experience with the craziness that is the Tucson Gem and Mineral Shows.

It rained almost all the way to Tucson from Organ Pipe National Monument. I got into the outskirts of the city before noon. I’d used Google Maps to direct me to a laundromat and it’s probably a good thing that I did. When I went into the camper to fetch my laundry, I saw that my roof was leaking.

I stripped the bed and set up pots and pans under the leaks atop a rubber-backed mat. My goal was to keep my bed dry.

It looked bad. Water was pouring in around the big skylight over the bed and through seams in the sealing slightly forward than that. My comforter was catching most of it. I moved quickly, fetching pots and pans out of the drawer under the stove and positioning them to catch the water. This was not a good situation, but I admit that I was surprised. I’d been in the camper in heavy rain before and had never had a leak.

That’s when I noticed that the skylight wasn’t fully closed. It was open just a tiny crack. I pulled it down the rest of the way and latched it securely. Could that have anything to do with the leaks?

Once the situation was under control, I brought my laundry in and sorted it into two washers. Then I went back out to pull my comforter out from under the pots and see how much water had soaked through. I was lucky; very little water had gone through to the blanket and sheets, which were pretty much clean. I brought the comforter into the laundromat and threw it in a dryer.

Then I went back into the camper with Penny and heated up a can of menudo for lunch. Nothing like hot soup on a cold day.

First Shows

Not my first timeI should clarify something here. This isn’t my first experience with the Tucson Gem and Mineral Show. I’d been to the show once before, in 1995. That’s the winter I lived in Yarnell, AZ to get away from the cold winters at home in New Jersey. My future wasband flew out to join me and the two of us drove down to Tucson, badly damaging my MR2’s front bumper in an accident along the way, to meet up with my future wasband’s cousin, Rick. Ricky believes that certain crystals have certain metaphysical properties that can make your life better. He was in Scottsdale visiting his aunts — really long story there — and met up with us to go to the gem and mineral shows. We were late (because of the accident) and he was pissed.

I honestly don’t remember much about that trip except a general feeling of being overwhelmed. I don’t know what shows we attended, although I don’t remember any of them being big. And I don’t remember what, if anything, any of us bought. I don’t think a trip could be any less memorable. Maybe it’s because I was still stewing over my accident and that nasty dent in my bumper.

After I had lunch, empty and repositioned the pots and pans under the leaks, and got my clean, folded laundry stowed into the dining area of my camper, I headed toward my first show. But before I tell you about that, let me tell you a little about the Tucson Gem and Mineral Shows.

Every year, from the last week or so in January to the second week or so in February, Tucson is basically taken over by at least 50 individual gem and mineral shows. They range from small shows in the lobby of a motel or the parking lot of a shop to huge, multi-tent shows spread out in big parking lots and expo centers. There’s an app to keep track of them, but it isn’t very well designed; it just tells you where each show is and lists each show’s vendors. You basically have to know which show you want to go to to make the best of the situation. I didn’t know where I wanted to go. And worse than that, I was driving a truck and pulling a 12-foot cargo trailer that I would have to park at each show.

While water dripped into pans on the bed, Penny’s bed was relocated to my dining table. She didn’t seem to mind.

But while I waited for my laundry to dry, I did some research with my friend Google. I knew I wanted to go to the show at the Kino Gem & Mineral Show because that’s where a friend of mine was showing his lapidary work. I also wanted to go to the JG&M Expo, which was a wholesale show. I had a list of possible shows and I separated them into areas. I figured I could hit at least two of them that first day, which was a Sunday.

So I headed to the Kino Sports Complex. I found a parking spot not far from the main area, near a few other large vehicles or trucks that were towing trailers. It was still raining on and off and there weren’t many people out and about. That’s probably why parking was so good for me. I put Penny in the camper and adjusted the pots and pans on the bed. The dripping had pretty much stopped, but I left the pots and pans in place. I made sure Penny had plenty of food and water and left her alone, locking the camper door behind me.

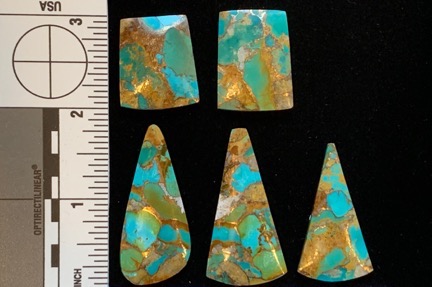

The Kino show was mostly smaller tents, although there were a few large ones with multiple vendors inside. Very much like what I’d seen in Quartzsite the previous month. The very first vendor I found was Nadri Gems, my source for about 90% of the cabochons I bought in Quartzsite. The guy I usually worked with was there, too, and he remembered me. (How could he not, considering I’d spent about $500 so far?) Knowing this would be my last chance to buy the kind of stones they sold, I filled a tray and made another big purchase. He took about $20 off the total for my purchase.

I walked around the rest of the show, looking at various merchandise. I bought some cord to fix a wind chime I have and a bunch of beads from another vendor who had been in Quartzsite and had already pre-qualified me for wholesale pricing. I was looking for turquoise and certain tools — that was my main reason for coming — and wound up buying a few small turquoise cabochons from a vendor in a big tent that had water running over the astroturf on the ground beneath the booths. (I was glad I’d worn my hiking shoes; the soles were thick enough to keep me above the floodwaters in various places I walked.) I got into a conversation with him about Sonoran Sunset, a stone that had been in high demand from my customers. He told me “there’s a guy set up behind the Howard Johnson who sells that.”

I kept walking around. A lot of the booths were closed because of the rain. I never did find my friend’s booth. There was just too much to look at but it was the same stuff over and over. After my long drive, camper leak situation, and laundry, my internal battery was down to 50%.

I went back to the truck, let Penny out for a run around the wet parking lot, and got into the truck with her. Then I told Google to take me to the next show, JG&M. I was very surprised to find that it was actually quite close by. In fact, I could have walked. Instead, I parked outside the gate where there was room for my rig and walked around the fence to the main entrance.

This was a huge show — actually three shows: Gem Mall, Holidome Show, and JG&M Expo — set up in multiple huge tents. I had to register and because I have reseller information, I could get a wholesale buyer badge. This is a huge benefit to me because it saves me the cost of sales tax. (The jewelry I make is taxed when I sell it.)

Inside the tents were mostly beads. Honestly — I don’t think I’ve ever seen so many beads in my life. All kinds of beads, all kinds of prices, all kinds of gimmicks and sales to get you to shop at one booth rather than another. There were “bead shows” in Tucson, too, but I couldn’t see any reason to go to them after seeing all the beads at this show.

I did wind up buying some beads. I had a blue opal cabochon that was blue and dark gray. I wanted beads to match it so I went from booth to booth and pulled out the cabochon to match. I eventually found what I was looking for at a price I was willing to pay and bought them. I didn’t buy much else, though. Other than beads and imports and finished fine jewelry for jewelry stores, there was nothing much else that interested me.

Well, on second thought, that isn’t really true. One guy did have leather necklaces with sterling clasps that I use for my pendants. Good prices. He also had some display items, including a “neck” that could hold seven chains. I stocked up on the necklaces and bought a neck.

Penny waited for me nestled into my comforter, which I’d stowed on the dry side of the bed while in transit.

When I was finished there — understand that I really breezed through — I decided to try to track down the guy with the Sonoran Sunset. I asked Google to take me to the address of the Howard Johnson. For the first time, Google failed me. It led me to an address inside the local university property, nowhere near where I wanted to be. (Yeah, I know: operator error; garbage in, garbage out. But Google should know what I want!) I pulled into a parking lot and tried again. Fifteen minutes later, I was driving on a narrow road past a handful of small motels, including the Howard Johnson. There were tents set up just about everywhere, but because it was getting late — nearly 5 PM — and the weather was still iffy, many of them were closed. But I figured that since I’d come that far, I should go all the way. I found parking in a muddy lot nearby, left Penny in the truck, and went in search of the Sonoran Sunset seller.

And this is where it got weird.

You see, the motels had been rented out to gem and mineral dealers. They had stripped the furniture out of their rooms and set them up as little showrooms. So as I walked past the doors to the motel rooms, they were all open with their front window curtains pulled aside and set up as shops. One after another with cases of stones. No beds, no night tables, no furniture at all. Just display cases. In some cases, they’d even draped the walls with curtains so the rooms had absolutely no resemblance to a motel room.

I wandered around, past the rooms and tents that were open. I looked at a few things. I never did find the Sonoran Sunset guy. He was either set up in one of the closed booths or not there at all.

Casino Del Sol

By this time, it was getting late, my internal battery was down to 20%, and I was very interested in finding a place to camp for the night before it got dark. My WIN friends in Organ Pipe had mentioned Casino del Sol so I asked Google to guide me there. It choose a weird route through a few neighborhoods but eventually put me at the entrance to the parking lot for a hotel casino complex.

Understand that Arizona does not normally have gambling. Most native American tribes, however, do have gambling. I’m pretty sure this one was for the Tohono O’Odom tribe. I call it the Indian’s Revenge — they suck us in to gamble and make money to support their people. I’m not a gambler, but I have a certain affinity for casinos — one of my favorite ways to spend a day in Vegas is walking the strip, through as many casinos as possible to see how outrageous they have become.

Casinos, of course, usually make an excellent overnight parking spot for RVers. Not only do they have big parking lots and access to restaurants and other amenities, but they also have excellent security. I’ll take a casino parking lot over a truck stop (or Walmart parking lot) any night.

Casino del Sol took overnight RV parking to extremes. There had to be at least fifty rigs parked in one of the outer lots and some of them looked as if they had been set up there for a while. This wasn’t parking — it was camping. I later found out that they had a two-week limit for free RV parking. Two weeks! No wonder so many people were camped out there.

I parked on the other side of a parking lot divider from a motorhome. Penny and I got out just as the motorhome’s owners got out. “Do you mind me parking here tonight?” I asked. I’m pretty sensitive to people parking right next to me and wanted to make sure they weren’t.

“Oh no, not at all,” the woman said. That started a conversation about where I was from and what kind of dog Penny was. I asked about restaurants in the casino. I was thinking about prime rib again. “There are restaurants,” they told me. “But they’re expensive.” They told me about a certain special on a certain night of the week that was a good deal. I don’t remember the details because I knew I wasn’t going to be around. Then they got into a car with another couple and drove away in search of a cheap dinner.

After settling in Penny, I went in for dinner. The steak place, which was supposed to be really good, was closed on Sunday nights. (WTF?) I wound up having Chinese food and sushi. It was good. It was my first meal in a restaurant in over a week. While inside the casino, I discovered that there was another gem and mineral show there, To Bead True Colors/Colors of the Stone, although it was closed until 10 AM the next morning.

Back in the camper, I stowed the pots that had been collecting water earlier in the day. The leaks had stopped — but so had the rain. I put away my laundry and made the bed, which was remarkably dry. I got everything organized.

And then I went to bed.

Breakfast and the Casino Show

I made myself coffee in the morning and took Penny for a walk. Beyond the regular parking lot was a gravel and dirt area where even more people were parked with RVs. We walked between the two areas. Then I put Penny in the camper and went into the casino for breakfast and to check out the show.

I learned a lot at breakfast. I sat at a table for two in the outer part of the only restaurant that served breakfast and they sat another woman who was by herself at the table next to me. She was a jewelry maker from Toronto who came to Tucson every year. She used her budget to cover the cost of transportation, a room in an AirBnB, jewelry making classes, and tools and materials at shows. She was having breakfast before going to the show in the casino.

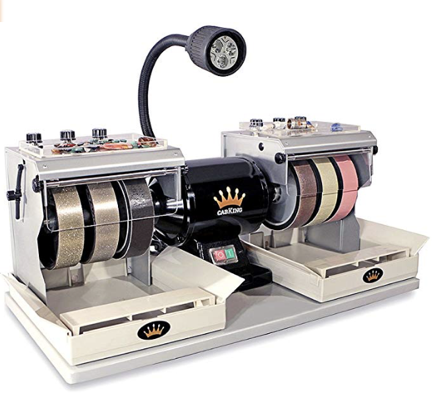

We chatted for quite a while. I realized that I had the wrong focus in Tucson. I shouldn’t be buying stones and other materials — I could get that cheaper in Quartzite in January. Instead, I should be focusing on educational opportunities and seeing demos of tools and equipment I might find useful for my work. I should be building skills and getting new ideas. She gave me some names and I jotted them down. It will completely change how I approach Tucson next year.

Words of Wisdom from an Unlikely SourceSome of the few actual words of wisdom I remember from 29 years with my wasband is this: “Any job is easy when you have the right tools.” (He used to say that when we watched “This Old House” or “Yankee Workshop” on PBS.) Every time I buy the perfect tool for a task, I think of that.

I have a shit-ton of tools now and lots of jobs that were impossible for me 10 years ago are now very easy.

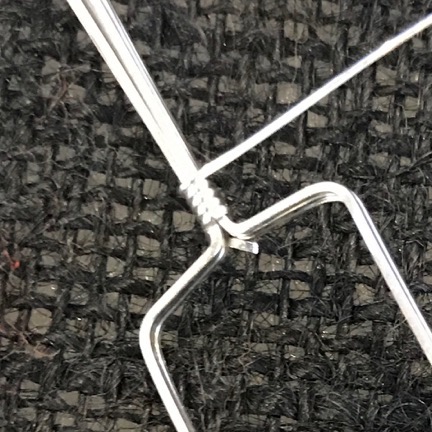

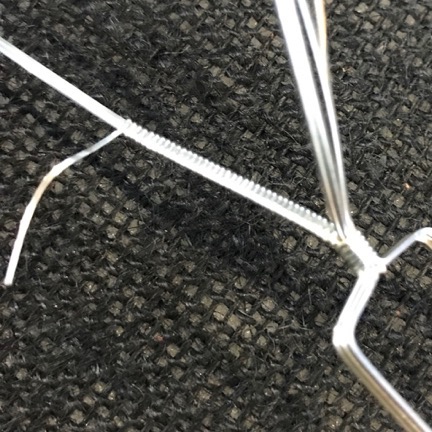

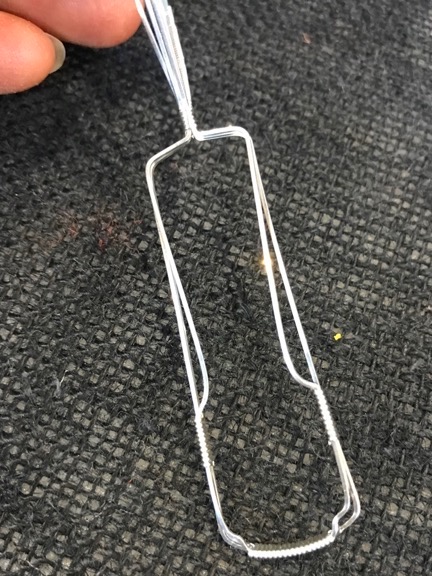

I got on the express line to sign up as a wholesale buyer for the casino show and, with my badge hanging from a lanyard, went in. This show had a lot more of what I’d come for: tools. I saw a few demonstrations and even got hands-on experience stamping metal the correct way (with the correct tool). I also learned the most valuable thing I learned in Tucson: how to quickly and effectively polish my wire framed pendants. (Hint: it involves a Dremel (or flex shaft) and a specific radial polishing wheel.)

One of the booths sold the full range of Wubbers hand tools and had two women doing demos — they just happened to be the founder of Wubbers, Patti Bullard, who had designed all the tools, and her daughter. Their demos gave me some great ideas for new bracelets and chains; I bought three of their tools. (You can see Patti Bullard’s tool demos on YouTube.)

In just 10 minutes, Patti Bullard showed me the basic skills I need to make bracelets and chains like these. I’ve since made a prototype of the beaded bracelet in copper.

I also found a booth selling precious metal clay tools — I’d decided to explore that when I got home — and bought a few items to make it easier for me to get started. There were lots of hands-on classes going on and I regretted not planning ahead and signing up for some of them.

Two More Shows

I was done before noon. I took Penny for another walk and pulled out with my rig, which I’d already prepped for traveling. My destination was the JOGS Tucson Gem and Jewelry Show at the Tucson Expo Center. Google Maps guided me. I ended up at a huge X-shaped building near the freeway. The parking lot looked crammed. Against all odds, I drove in, stopping by the valet parking station to ask where I might park. The guy was very friendly and pointed to an area with a few U-Haul trailers. I thanked him, squeezed into a narrow entrance to a disorganized dirt lot, and backed into a spot next to a U-Haul relatively close to the main entrance.

I went in, registered as a wholesale buyer, and walked into the show. The very first booth I saw was all tools — exactly what I had been looking for. Well, not exactly. The truth of the matter is that what I really hoped to buy in Tucson was a large jeweler’s anvil. Spoiler alert: I did not find one. But I did look at a lot of different tools for different jobs.

The rest of that show was about 60% beads and 20% fine jewelry for resale. There was another Nadri Gems booth — those guys are everywhere — and I bought two very nice azurite with chrysocolla cabochons. I bought some more beads. I bought some display pieces. Although I tried to do the building without wandering off path too much, I eventually failed, lost track of where I was, and had a senior moment: which way was out? Too many of those bead booths looked too much alike. I finally got back on track and headed for the exit.

There was a food court outside and I treated myself to Salvadorian food — a sort of thick-shelled soft taco with beans and chicken. Tasty.

I went back to the truck to stow my purchases and let Penny out for a walk. I liked my parking space and I knew that my next destination, which was closer to downtown Tucson, would probably not have such accessible parking. So rather than drive, I put Penny in the camper, locked it up, and called a Lyft.

I was headed for the Kent’s Tools Jewelry & Lapidary Tools and Supply “Show.” I put “show” in quotes because when I got there, the “show” consisted of one guy who made cabochons and did pretty basic wire work under a tent in front of the shop’s entrance. The shop, of course, was Kent’s Tools, which is like a candy store for anyone who is serious about making jewelry or working with stones. This shop has everything — although it was out of stock on the anvil I was looking for — with good prices and a knowledgeable staff. I bought some texturing hammers, a soldering tripod with screen, a metal stamp, some polishing wheels, a brass hammer, and a bunch of other things to outfit my shop at home. All my purchases fit in a big shopping bag. Lyft took me back to JOGS.

Another Night, Another Casino

At this point, I felt done. It was late afternoon and I’d bought most of what I’d come to buy. I didn’t feel capable of looking at another single bead and knew that any show I went to would have lots of them. So I decided to try Tucson’s other casino, Desert Diamond, for an overnight parking spot. It was near the airport and a lot closer to the freeway than Casino del Sol.

The Desert Diamond Hotel.

There were a lot fewer RVs parked at Desert Diamond, and that was okay with me. I found a parking spot on the edge of the lot, not far from an open area where Penny could run loose. Rather than go in for dinner, I decided to have a light meal in my rig and try to organize some of the things I’d bought.

I was asleep by 9 PM.

I the morning, I went into the casino for breakfast. I walked in through the nearby hotel entrance because it was chilly out and I didn’t want to spend more time outdoors than necessary. I got a real treat along the way. The hotel’s design and architectural details are reminiscent of Frank Lloyd Wright, making a pleasant walk through the space.

The hallway outside the hotel’s conference rooms and the detail from a door between the hallway and casino. Nicely done!

Breakfast was okay. The only place open was the buffet, which was nearly deserted on that Tuesday morning. I had a fresh-made omelet, too much breakfast meat, and some yogurt with granola. I hate eating at buffets because I always eat too much — although I usually love the variety.

The Metal Bar

I had gotten the idea — okay, I got the idea from YouTube — that I could use a piece of railroad steel as an anvil. The trick, of course, was finding a piece of railroad steel that was only 1 to 2 feet long.

So after breakfast, I worked my phone. I called a handful of metal fabrication places in Tucson and hit what I thought was pay dirt at one of them: the guy I spoke to was pretty sure they had a piece of railroad steel somewhere “out in the yard.”

Of course, when I got there, no one knew who I’d spoken to or what I wanted. No one seemed interested in looking around the yard, either. One guy, trying to be helpful, showed me to an area where they stored rolled steel. They had these two inch square solid bars with rounded edges. I asked if they could be cut. “Sure,” he said. I saw that the price was 83¢/pound and wondered what a one-foot long bar would cost. More than $100? He laughed. Probably about $15.

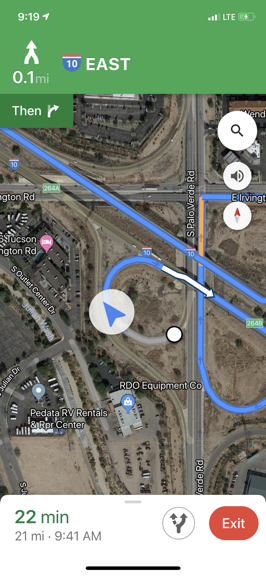

Ugh! I missed my turn for I-10 heading westbound out of Tucson and Google Maps guided me in a convoluted U-turn. Operator error!

So I told him I’d take a foot. I went to the checkout area and chatted with them men there. One of them had a hobby of making guns and he showed me a few photos on his phone. A few minutes later, a man came in with a one-foot long piece of the solid steel bar. They weighted it: 14 pounds. With tax, it was about $13. I carried it out to my truck and stowed it behind the back passenger seat.

One Last Stop

I did have one last stop to make on my way out of town: an outlet mall just off the freeway. I needed a new pair of jeans and I like to wear Levis. So I hit the Levis store and walked out with two new pairs of jeans.

My next stop was a lunch date in Mesa, AZ. I hopped onto I-10 westbound and headed north.