I take the camper to Tacoma to learn more about making jewelry.

Note: I actually wrote this and much of

the post after it about my new cargo trailer back in early October while I was still traveling. I can’t tell you how many blog posts I start writing and don’t finish. This one’s done. I’ll try to get the other one done this week, too.

Last September, I took a 3-day intensive beginner metalworking class at the Tacoma Metal Arts Center in Tacoma, WA. It was an amazing experience that really transformed the way I think of making jewelry. I learned a bunch of metal working skills and how to use new (to me) tools that would take me to the next level in my work: cutting, soldering, texturing, shaping, and polishing sheet metal using jeweler’s saws, shears, torches, flex shafts and attachments, dapping blocks and punches, rolling mills, texture plates, and burnishing tools. I left class with the basic tools I’d need to practice what I’d learned.

Getting Serious about Jewelry Making

Over the winter, I decided to get serious about making jewelry. I paid a contractor friend to frame in a 12 x 24 foot space in my absurdly large garage so we could make an insulated shop for me. That would give me a climate controlled space to work on jewelry projects. While I was in Arizona over the winter, I shopped for the tools and equipment I’d need to set up a full-blown annealing/soldering station and jeweler’s workbench. When I returned from Arizona, I ran the wiring in the new shop and my friend returned to put in the insulation and drywall while I fastened T1-11 paneling to the two outside walls facing into the garage. Then I painted the inside of the room and added some trim around the windows. I installed the two glass-paned doors last week with another friend. The room is large and bright from its two windows and four track light setups, with an 8-foot ceiling and 288 square feet of loft space above it that I’ll likely never use.

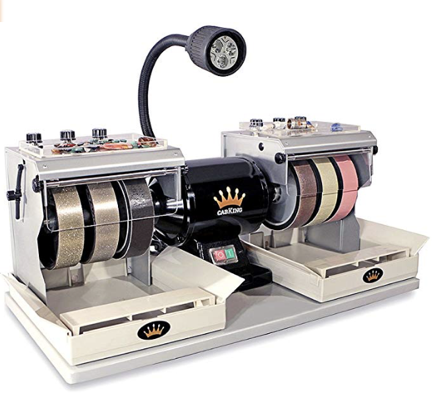

With the help of the folks at Rio Grande — my primary supplier of metals — I purchased a few rather costly quality tools: a Durston rolling mill, a Swanstrom disc cutter, and a PepeTools ring bender. I also acquired a set of dapping blocks/punches and a metal shear almost as good as a true guillotine style cutter. I moved my jeweler’s bench into my new space, putting it right beneath one window where I’d get plenty of natural light. I built a solid workbench for the corner where I bolted down the rolling mill. Then I moved in the rolling storage cabinets I’d been collecting for years, set up one as my soldering station, another as my rock storage and jewelry photography studio, and a third as storage for the display and packaging equipment I’d accumulated. Half the room is set up as a jewelry studio while the other half is my regular workshop with the big workbench I built several years ago, my tool chest, and the rolling cart I’d converted into a storage and charging area for my power tools. My table saw, miter saw, tile saw, and Cabking cab making machine remain in the garage, on the other side of the wall. (The room is big, but not that big.)

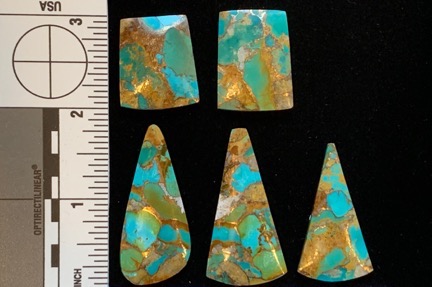

Now, in addition to the sterling silver and/or copper framed gemstone cabochon pendants I’ve been making for a while, I also make textured and etched silver and copper earrings, soldered silver and copper stack rings, hammered bangle bracelets, silver plated “spoon rings,” and novelty keychains. This gives me a full range of products to offer customers when I show and sell my jewelry. I make these items in my shop and make my cabochon pendants when I go to shows.

This summer, however, I realized that I was ready for more.

Classes at the Tacoma Metal Arts Center

The Tacoma Metal Arts Center (TMAC) offers a variety of jewelry classes. Although I wanted to take the three-day course again with a different instructor to polish my skills and learn things from a different person, the dates and times it was offered did not work with cherry season, which requires me to be at home every day for three months — roughly June through August. There were a few one-day classes in September and October that looked interesting, but I wasn’t interested in coming to Tacoma for just one day. And then I saw the two one-day classes offered on the weekend of October 12 and 13: Molten Magic and Possibilities of Precious Metal Clay.

Molten Magic’s description was as follows:

Ruth [the instructor] will show you how to cut a shape from copper sheet for your project, then you will cover it with texture through the molten magic of melted silver! The result is a wonderfully rich surface texture of ridges and waves. Then, you will learn how to apply an iridescent patina with a torch by flame painting the surface.

Possibilities of Precious Metal Clay was described as:

PMC (aka Precious Metal Clay). Create fine silver jewelry from a clay: this material works like earthen clay so it can be shaped and formed, textured and refined and then fired. The result is precious metal in pure silver. Once it is finished into silver you can polish it or apply a patina for that vintage look.

These two seemed perfect for me. I was interested in taking my sheet metal work to the next level and fusing silver and copper sounded very interesting. As for PMC, I had actually bought some of the stuff and a bunch of tools to work with it but because of its cost, I was hesitant to get started. This would give me the information I needed to try it with confidence — or realize that it wasn’t really for me.

I signed up and planned to spend the weekend, camping out in their back parking lot in my truck camper as I had done the year before. Not only would I save on overnight lodging, but I could bring Penny the Tiny Dog along.

Molten Magic

Although I’d been hoping to get to Tacoma the evening before Saturday’s class, a big project at home kept me busy until 4 PM. By the time I prepped the camper, it was 6 PM and sunset was less than 30 minutes away. I try hard not to drive in unfamiliar places at night, so I didn’t depart until 5:30 AM the next day. Of course, I still had to drive in the dark over Blewett Pass, which I seldom drive. It wasn’t light until I got to Snowqualmie Pass.

To give you an idea of the variety of food items Metropolitan Market offers, he’s a shot of some of the mushrooms they had for sale that day.

Traffic was light and I got there early. So I kept driving and stopped at Metropolitan Market, a supermarket that is so posh it makes Whole Foods look like a Smart and Final. I parked in the lot, got out to visit the restroom and buy some snacks, and then took Penny for a walk down the adjoining residential street. Then it was back to the TMAC, where I drove into the alley behind the place and backed the truck into the narrow parking area, trying (and failing) to use up only half the width of the space. The back gate was locked (as I knew it would be), so I got Penny set up in the camper with food and water, locked it up, and walked around front to the main entrance.

I was the first student to arrive. I met the instructor and chatted with her for a while. She must have thought I was a nut, talking to her as if I’d known her for years. I do that. The second of four students arrived before the 10 AM start time. The third arrived loudly 20 minutes late, after class had already begun. The fourth never arrived.

The instructor, Ruth, did not have a very structured teaching style. It was all very casual. There would be no specific project. Instead, she told us about the techniques we’d be using, handed out sheets of copper and scraps of sterling silver, and encouraged us to practice on the copper scraps in a bin near the rolling mill. Then she took us back to the polishing and soldering stations and demonstrated how to clean off the metal with wheels on three bench grinders there and then use heat from a torch to oxidize the copper enough to get different colors and patterns. She showed us how to melt silver onto the copper, including how to somewhat control how the silver melted by using heat to guide it across the copper.

Then she let us go to it.

There were three soldering stations and three of us so it worked out well that the fourth person hadn’t shown up. We each played with the sample copper for a while. One of the scrap sheets I’d taken had been run through the rolling mill and had a pattern on it. I managed to get shades of orange and pink on it. Later, I’d turn it into a pair of twisted metal earrings suitable for sale. (Yes, I can make jewelry out of scrap metal.) My silver melting wasn’t quite as interesting. I couldn’t come up with a suitable shape, so I’d traced a plastic spoon. No matter how I looked at it, it looked like a spoon. And I didn’t like the way I melted the silver on it.

Meanwhile, my two companions were working on nice projects. I felt uninspired. And disappointed. You see, I had already played with “fire painting” copper so it wasn’t new to me. The only thing I’d learned was that you could polish off the color to start over — I normally used “pickle,” which is an acid that removes oxidization — and that it was possible to melt sterling silver with the same little butane torch I used to solder and anneal.

Ruth spent a few minutes showing us how we could create a chain for a pendant using sterling silver wire and jump rings that she provided. I liked the chain on the sample piece she’d brought along, but it had been created with 14 gauge wire and she’d give us thinner 16 gauge wire. I played around with it for a while but didn’t like what I was doing.

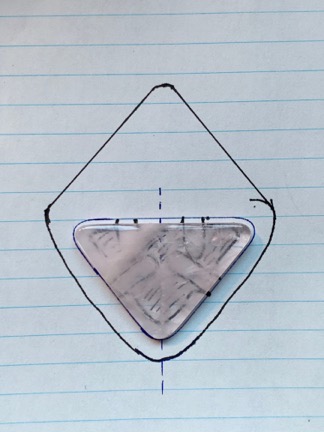

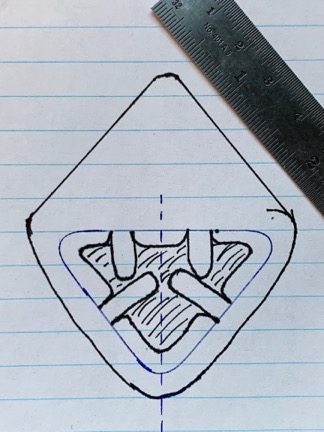

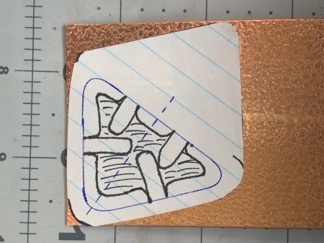

Here’s the pendant I made in class. I finished it with a leather necklace and added a pair of matching earrings. They sold as a set on the first day I displayed them in my booth.

Then I got an idea for a pendant that would consist of three textured copper panels, each of which had silver wire melted on it. I’d join them together with jump rings. So I cut some of the copper sheet and went at it with two different hammers. Then I took some of the wire she’d given us to make a chain and made a zigzag pattern with it. I made tiny dots with more wire. I melted the wire to the copper without allowing the zigzags to get completely molten so they were fused onto the copper without losing their shape. I polished off the oxidation and then used the torch to apply just a tiny bit of color. I liked the result. I fetched some copper jump rings from my camper, colored them a bit with the torch, and put the whole thing together. Funky, but I liked it.

By this time, the day was pretty much over. Amy, the owner, came in to do some paperwork and she took photos of what we’d made. I felt that I made a respectable showing; everyone seemed to like the pendant and earrings. My companions had created more things than I had, but I didn’t mind. I had some ideas and that’s all I needed.

More at Metropolitan Market

After class, I went back to the camper — I’d checked on Penny at lunchtime — and put Penny on her leash. We walked the mile or so to Metropolitan Market. I parked Penny at the outside dog parking area where an Australian Shepherd was waiting for her human. I bought some things for dinner from their extensive prepared food area, remarking to the person behind the counter that if I lived nearby I’d be 300 pounds and flat broke.

Penny and I shared a gelato — I scooped some of mine out into the lid of the container for her — and walked back. Then we climbed into the truck and drove to a local U-Haul place that filled propane tanks. One of my tanks was completely empty and the other was only 1/4 full. I did not want to run out of gas overnight. That done, we returned to our parking spot and I backed all the way in so my back door was only a few feet from the back gate.

I heated my dinner in the camper’s oven — I wasn’t plugged into power and hadn’t brought along a generator so the microwave was useless — and worked on some earrings while I waited for it to finish heating. After dinner and another quick walk with Penny, I stretched out on my bed to read.

I slept well. During the night, I was treated to a rainstorm. The only thing I love more than hearing rain on my camper’s roof is hearing it on the metal roof of my home.

The Iliad and The Odyssey

I was up at 5:30 the next morning. I lounged in bed for a while, like I do at home, and then got up, threw on a pair of sweatpants, and made my coffee. I did a little web surfing at the table while I had my coffee. Before I knew it, it was 7:30. I made breakfast and ate it as Penny came down off the bed to let me know she was ready to go out.

I put the leash on her and we walked down the alley. There was a Bartell’s pharmacy about two blocks away and it looked like the kind of place that might have a refrigerator case. I really felt like having some orange juice. They had every sugar or alcohol drink in that case except real orange juice.

We crossed the road to a coffee shop. They didn’t have orange juice either. But they had a nice staff that let me bring Penny in so I bought a latte and caught up on Twitter at a table near the window while Penny ate a dog biscuit and a nearby dog watched her.

At one point, a young guy came over and complemented me on how well behaved my dog was. That got us into a conversation about dogs in public and how the owners really needed to keep them under control. I pointed to the other dog. “That’s a well-behaved dog,” I said.

This is the edition recommended by my friend.

I noticed that he was reading The Iliad and asked him if he was reading it for a class or if he was just reading it. He told me that he’d always wanted to read the classics and figured he’d start with the first one. (At that point, I found myself wishing he was about 20 to 30 years older and single — I felt the same way about reading the classics but needed a bit more motivation to actually do it.) I had recently explored reading a specific translation of The Odyssey that a friend had recommended. I told him about it and looked up the translator’s name for him. He said that was next on his list and he’d look for that version. I think he really will.

Possibilities of Precious Metal Clay

By that time, it was 9:45 and I was running the risk of being late for class. So Penny and I hurried back. I put her in the camper and went into class. I arrived at about the same time as one of the previous day’s students, Ellen. Two other students joined us. Again, there was a no-show.

This instructor, Meredith, had a more structured approach — but not much more. She spent some time talking about PMC — what it is, how it works, etc. She sent around examples of her own work — some of it with problems she pointed out as examples of what can go wrong. She handed out 9 gram packets of PMC3, bunches of 10 standard playing cards (which are used to gauge thickness for rolling), tiny pieces of plastic needlepoint grid (for a simple texture, a small sheet of foam (for creating our own textures), and long pins with masking tape flags on the end (for cutting clay). She seemed a bit disorganized; she’d forgotten to bring along work surfaces for us. Instead, we’d be rolling out the clay on the same teflon surfaces we’d use to dry it on. All the other tools were laid out in piles on unused benches and workspaces.

And then she let us go to it, again, without a specific project.

I guess wanting a specific thing to make is something that affected me more than my companions. I suspect that it’s because I’m pretty new to art — so new that I usually don’t provide a straight answer when people ask me how long I’ve been making jewelry.

Although I’m a visual person when it comes to learning, I’m not visually creative. (My creativity has always come with words; I have always been a writer.) Show me how to make something specific using a set group of techniques or skills and I’ll make it. Then, as I make it over and over, the creativity comes out. You can see that in my silver framed jewelry. Dorothy taught me how to make a pendant in her style using her materials and tools. The more pendants I make, the more my materials, tools, and final products differ from hers. I look at a stone and I think about how I could make an interesting pendant from it. The idea clicks and I make something creative and new. But when it all comes down to it, I’m just doing the same thing over and over, with minor twists that make something new.

Although Ruth had provided a project idea — the sample pendant she’d made for the course description — I hadn’t been interested in duplicating that. And Meredith did provide many examples of what we could do with PMC, but there were too many. I guess I was expecting her to walk us through the process of creating some of these things rather than giving us an overview of how to make them and then answering questions to help us complete our own personal products.

My problem was that I lacked ideas.

I made two textured pieces that could be earrings or charms. It took only minutes to do, even with the custom texture I created in the foam I’d been provided. I was interested in creating a bead and had picked out a small piece of cork clay to form a bead around. I had a few false starts — you have to surround the cork with clay before applying a texture (duh). My mistake was choosing such a small piece of cork; it meant that I was working with a very tiny object. But the damn clay is so expensive that I can’t imagine using it to make anything large. And we’d only been provided with 9 grams of the stuff so I was afraid to use too much right from the start.

Around lunchtime, Meredith set out a timeline for the rest of the class. All of the pieces had to be fired for about 45 minutes in a kiln. It took 30 minutes to ramp up the kiln to 1470°F. After that, we’d have to brush, tumble, and burnish our pieces, which would take at least another 15-30 minutes. With the class ending at 4 PM, that meant we’d need to get everything in the kiln by 2:30 at the latest.

I decided to use the rest of my clay to make a rectangular pendant with shapes adhered to it. This would enable me to practice “gluing” pieces together. What I made was ugly, but it did let me practice techniques. I worked and fine-tuned my pieces until 2:15 and laid them all out on the heating pad with the others to dry.

Compared to everyone else’s work, mine was pitiful. I didn’t even take a photo of them.

Meredith loaded the main kiln, which she’d brought along with her, and, while the kiln was coming up to temperature, talked to us a little about kilns. She’d brought along a smaller kiln designed for enameling that also worked with PNC and wound up firing that up for a few more pieces. Then we waited, asking questions and looking at more examples.

Finally, it was done. Meredith opened the kiln shortly after it was finished firing, opening and closing the door at short intervals to cool it slowly. She pulled out and quenched our pieces in a bowl of water. As I expected, they were all covered with a white film. She had us brush them off with a brass brush that put scratches in my pieces. I was pleased to see that none of them had any problems, although none of them had gotten any nicer.

Then she prepped the tumbler and dropped all of our pieces in. We cleaned up our workspaces while we waited. The owner, Amy, had come in and we shopped. TMAC is an excellent source of jewelry making tools and equipment at reasonable prices. I bought a small hand drill and two silver hallmarking stamps (.925 and .999FS).

Out of the tumbler, my pieces still had a lot of white residue on them. Meredith told us to burnish them with steel. I found a suitable tool and went to work on one of the pieces. The silver shine popped out. So now it was ugly and shiny.

Of course, I’m half joking here. Although my work wasn’t anything to be proud of, I had learned quite a bit about working with PMC and am no longer afraid to play with the 30 grams I bought earlier this year. I’m hoping to get my tiny desktop kiln running again; it’s the perfect size for this kind of work.

I just need some ideas.

After Class

Although I’d originally planned to spend the night in Tacoma, it was early enough to get a start for my next destination: Yakima. I needed to pick up a cargo trailer that I’d be converting into a mobile jewelry studio.

But I think you’ve read enough here. I’ll cover that in another blog post.