Responsible gun owners get professional gun training.

My certificate of completion.

Earlier this month, I was a participant in an NRA Basic Pistol Course. The course was privately conducted at a friend’s home in the Wenatchee area, with the shooting portion done at a private makeshift shooting range on another person’s property. It lasted two days and although I had to leave early on the first day to attend a mead-making course I’d signed up for in Leavenworth, I caught up on the second day and met the course requirements well enough to earn a certificate of completion.

I’m not a supporter of the NRA. Well, let me rephrase that. I’m not a supporter of the NRA’s political lobbying arm. I didn’t realize this until the course, but the NRA has two distinct organizations. The one I don’t mind supporting is the one that promotes firearm safety, training, and awareness. The one I won’t support at all is the lunatic lobbying organization that seems to have given people the idea that it’s okay to carry assault rifles into Target department stores. More on that in another blog post.

My Gun History

I took the NRA course because although I’ve owned my Beretta Model 21A 22 caliber semiautomatic handgun for more than 10 years, I’ve never really felt comfortable using it or handling guns.

The other day, I cleaned my gun for the first time in years. I can’t believe how dirty it was.

I got the gun back in the early 2000s, not long after moving into my Wickenburg house with the man I’d later marry. The house was on 2-1/2 acres on the edge of town. Although I would not consider it a “remote” location, it was certainly not what someone would call suburbia. The house was new and it creaked a lot at night. My future wasband would spend a week or more each month back in New Jersey for work and I was left alone. The creaks unnerved me — I remember sitting up in bed one night all night because I was convinced there was someone walking around downstairs. (There wasn’t.) I wanted a means to protect myself when my future wasband was away, so he bought a gun. I’m thinking it was a 357 Magnum. I know it was a big revolver. A scary gun. A few years later, I got my little Beretta and he traded in the revolver for a Glock.

Although I grew up with handguns in the house — my father was a police officer — I was not familiar with them. I wanted professional training. So we signed up for the only gun training course we could find in our area of Arizona: a concealed weapons permit course. It was an extensive course with classroom training and range practice. The course was led by a local gunsmith and his wife. They wore camo to each session. I was the only female attendee among about 6 or 7 men. When it was over, I had a card that made it legal for me to carry a concealed weapon in the state of Arizona. These days, I don’t even think you need a permit to carry concealed in Arizona. That state is whacked out and I’m glad to have it in my rear view mirror.

It’s important to note that I didn’t take the course for the permit. I took it because I wanted professional training.

Over the following years, we occasionally practiced shooting at a local range or out in the desert. It was a big deal when guests from New York came to stay with us and we took them shooting. But I never really got much practice.

Fast forward to 2013. I moved to Washington state, leaving my wasband behind forever. I bought 10 acres of property on an unpaved road overlooking the Wenatchee Valley. The word “remote” would certainly apply more to this home than my last one, although I do have neighbors within 1/4 mile. My gun, which had been traveling back and forth to Washington every year in my RV anyway, was something I kept handy. (I hate to admit it, but my wasband and the crazy old whore running his side of the divorce were acting so irrationally — going so far as to send a private investigator to try to snoop on me — that I worried about my personal safety.)

In 2014, I bought a new gun that would be handy for long-distance protection from animals, rattlesnakes, and other threats: a Remington Model 870 Tactical 12 gauge shotgun.

Of course, since it had been so long since I’d had formal training — or had even shot my gun — I wanted more training. I had my eyes trained on the Complete AK 47 rifles from Palmetto Armory I’d once visited and was fascinated. A gun is useless as a means of protection if you are afraid to handle it or use it. A friend of mine — I’ll call her Lacy — was also interested in getting some training. She set us up at the range to work with a local gun enthusiast who offered training for a fee.

The instructor — I’ll call him Gary — was very knowledgeable. I shot my Beretta for the first time in years and didn’t do too badly. I also got a chance to shoot my shotgun. That was quite an experience. The kick bruised my shoulder, so I learned to shoot somewhat accurately from the hip. Lacy got to shoot it, too. But this instructor’s politics were questionable. He kept them to himself for most of the time, but later started hinting that we needed to be armed in case the government came to take our guns away and we needed to fight back. Real survivalist stuff. I suggested that he might like living in Idaho.

The NRA Course

When Lacy arranged for the official NRA course to be held at her home, I signed right up. The idea was to have an instructor lead a class for a handful of women. Four of us were supposed to attend, but cold weather chased off two of them. In the end, it was me, Lacy, and the instructor’s mom, who had been shooting her whole life.

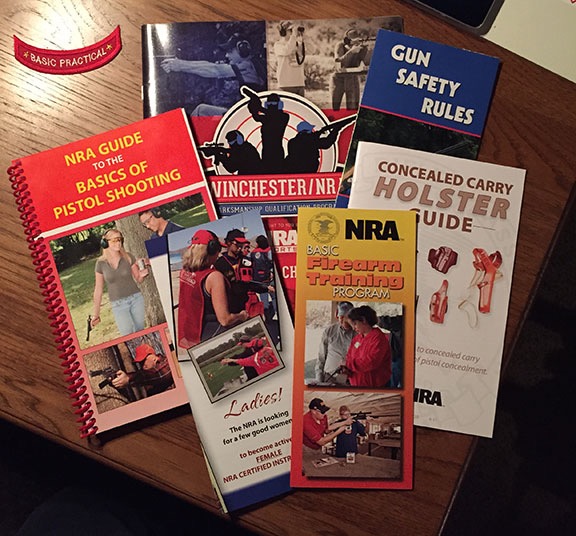

The course cost $50 and I’m pretty sure that all of it went to the instructor (who we paid), with a portion of it going to the NRA training materials and literature that we each got. Of this material, the 100+ page NRA Guide to the Basics of Pistol Shooting was very informative — a real keeper. The safety rules pamphlet was a good guide to handling firearms, but the same information was also covered in the book. Other material promoted additional NRA courses and solicited for women to become firearms instructors. The Concealed Carry Holster Guide was a 30+ page booklet with illustrations and descriptions of various holsters and clothing to carry a concealed weapon. I didn’t think there was that much to say about the topic, but apparently there is. There was even a patch that I could sew onto — well, whatever. I wonder how it would look on my old Girl Scout sash?

My $50 bought me 2 days of training and all this printed material. I admit that I threw it all away except the spiral bound book.

Gun Safety Rules

Because Steve quizzed us repeatedly on the three rules of gun safety, I came up with a mnemonic for them:

P – Point the gun in a safe direction.

T – Keep your finger off the Trigger.

L – Load the gun only when you’re ready to fire.

PTL = Praise The Lord. The PTL Club was a religious TV show hosted by Jim and Tammy Faye Bakker that I never watched. (I’m not religious.) I don’t know why this association came to me, but it did and it stuck and it works.

Praise the lord and pass the ammo.

This instructor — I’ll call him Steve — was a lot more “normal” than Gary had been. He’s the one who pointed out that the NRA was really two separate but related organizations. (I think it was a way to distance himself from the wackos.) He also made a clear distinction between open carry, concealed carry, and “discrete carry” that really made sense to me. (More on that in another blog post.) He was extremely safety conscious and quizzed us over and over on the three rules of gun safety. Although his presentation consisted primarily of NRA-prepared slides shown with transparencies on an overhead projector (!) he also had a wide variety of guns and other equipment to show us. I felt that his presentation was nicely done and complete.

My only complaint is his tendency to occasionally go off on a tangent — for example, spending too much time (on several occasions) talking about the types of ammo that were available. Did three 50+ women in a beginning shooter class really need to see a handwritten list of the 30-40 types of 38 caliber ammo presented on a whiteboard? All we really needed to know was how to find out what would work in our guns and some tips for choosing one type over another. This is just an example. Other than those few tangents, I think his presentation was right on target. (No pun intended.)

The range work was good, but not ideal — mostly because it was very cold with just enough wind to drop the temperature another 10 degrees. Lacy had provided hand and toe warmers and I had them open in my jacket pockets and shoes. Body parts that were covered were not an issue, but naked hands were. It was difficult to load the guns and I took every opportunity possible to shove empty hands into pockets and grasp those hand warmers.

Backyard Shooting Ranges

For those of you reading this in a metro area — especially back east — or in countries where gun ownership and use is severely restricted, the idea of a private shooting range at your home might sound odd to you. The truth is, there’s no reason why I couldn’t set up a range on my 10 acres of land and practice shooting at any reasonable hour of the day. Or shoot coyotes or other animals that threaten me, my dog, or my chickens. Hell, my Seattle transplant neighbors do it all the time, trying to live that “wild west” dream to the max.

Steve provided the guns. We shot with revolvers and semi automatic handguns. We shot single action and double action. The targets were paper dinner plates tacked onto a stand about 50-60 feet away. Beyond them was a berm. The “range” was at Lacy’s friend’s home. (Oddly, when I met the friends, I discovered that they knew another friend of mine from a trip to Wickenburg last winter. Small world, eh?) Steve was interested in us hitting the target as close to the staple in the middle as possible. (Real high tech, huh?) We all did fine, despite the cold.

Afterwards, we each got a chance to shoot our own gun with Steve. I let Lacy go first while I warmed up in my car. While waiting, I took my Beretta apart — following the instructions in the manual I had with me — and sliced my index finger open trying to get it put back together. (Yes! Guns are dangerous! It took over an hour to stop the bleeding!) I managed to reassemble it just as Lacy was finishing up.

I pointed out to Steve that one of the problems I had with my gun was jamming. I’d brought my ammo, which were CCL and Federal — both very good brands that he had recommended. He asked permission to fire my gun and I let him empty the magazine at the berm. Then we reloaded with Federal ammunition and I shot. The first empty shell was not ejected. Steve was surprised but after thinking about it for a moment he said he thinks it’s because the shell was bare lead and not jacketed. We emptied the Federal shells from the magazine and reloaded with the CCLs. It worked fine. At least I know what not to load.

It was too cold to do any more, so I left. Lacy and I will likely do some practicing up at the range when the weather warms up a bit. I might set up a range at my place to practice, too.

On Firearms Training

Would I recommend this course to anyone who owns a gun? Definitely.

But I’ll go a step further to say this: I believe that every gun owner should be required to take a professionally run gun safety or gun use course. In other words, I don’t think you should be able to buy a gun or own a gun unless you have a certificate or something on record proving that you’ve had gun training.

And frankly, I don’t see how that affects a gun owner’s “rights.”

Yes, this course cost me $50. But do you know what a gun costs? My silly little Beretta retails for $410. My Remington 12-gauge shotgun retails for $600. What’s $50 compared to that? An avid gun user would spend more than $50 on ammunition in a month.

And who’s to say it has to cost that much? Who’s to say that a larger class size can’t cut costs? Or that gun clubs can’t be certified to provide this training to members for free?

You want me to go even further? How’s this? I believe that any gun owner with children in the house should be required to attend a gun safety course with their kids. It doesn’t have to be long and it should be upbeat and fun while stressing the danger of guns — apparently, the NRA offers such a course. Kids need to know that guns are dangerous and shouldn’t be touched without supervision or training.

What? Kids touch guns? You think that’s okay, Maria?

Age and Maturity Level Matters

This is what happens when you give a 5-year-old a 22 caliber rifle.

The NRA and gun manufacturers apparently don’t think there’s anything wrong with marketing guns to kids aged 5 to 12. This is wrong.

While it is possible for a 10-year-old (for example) to be smart, mature, and responsible enough to safely handle a gun with supervision, I think that’s the exception rather than the rule. Think of the last kindergartener you saw — maybe you have one at home. How do you think that kid would be handling real gun?

Why does the NRA think this is okay? This is one of the reasons I can’t be a member of this organization.

Yes, I don’t see any reason why a mature and responsible young person — especially one living in a rural or remote area — can’t be professionally trained (like his/her parent) to safely use an appropriately sized/powered gun for supervised target practice or hunting. Of course, age and maturity level must be considered, and that’s likely where this would all fall apart because of the gun wackos out there. More on that in another post.

I do want to mention here that I received some very basic training and experience with a bolt action rifle back when I was in Girl Scouts. In suburban New Jersey. How old was I? Maybe 12? (Ah, if only Girl Scouts was as good now as it was back then. But I digress.)

I’ll summarize with this: the Basic Pistol Course I attended earlier this month — and the Concealed Weapons Permit course I took in Arizona years ago — provided me with a wealth of information about safely handling and storing guns, as well as how guns work. There is no reason why gun owners shouldn’t be required to learn — and be tested on — this material prior to owning or handling a gun.

Comments?

This is a hot button topic and I’ve stated some very strong opinions. I’m sure everyone who reads this has something to add. That’s what post comments are for.

But be warned: While I don’t mind readers sharing conflicting opinions, I don’t allow abusive comments, especially those posted by people who hide behind aliases. Comments here are moderated and I have zero tolerance for trolling. I have a Comment Policy and if you’ve never commented here, you should read it before trying to comment. It would be a shame if you spent 30 minutes getting all hot and bothered while composing a nasty comment aimed at me or another commenter and your comment never appeared. What a waste of time, huh?

And if you want to rant about how the government is evil and will be coming for our guns and how we need to rise up against “Emperor Obama”, go ahead. I can always use a good laugh.

There’s a new kind of typo in town.

There’s a new kind of typo in town.