What drives pilots at various career levels.

I’ve been flying helicopters since 2000, when I got my private pilot certificate. I learned to fly as a hobby but soon realized that if I wanted to fly, I needed an aircraft. Back in those days, I was earning a good living as a freelance writer and had authored two “bestsellers” in my field. I bought a helicopter and flew it in my spare time. I also worked toward my commercial pilot certificate, which I received in 2001, so I could fly for hire. After all, I wasn’t rich and who knew when the money from my writing career would dry up? Over time, I grew my business, bought a larger helicopter, and found a few lucrative niche markets for my services. Since the money from my writing career has pretty much dried up, I’m glad to have a solid standing in my flying career.

That’s the very short version of how I got to where I am today: an owner/operator with just one helicopter and a handful of regular clients, doing the occasional rides gig, tour, and photo/survey flight as need arises.

As I head home from two days of callout on a frost control contract in California’s Central Valley, I’ve been thinking a lot about what motivates pilots on each level of the aviation ladder: new pilots, experienced commercial pilots, and owner/operators. I’ve spent time in each group — although admittedly in unusual circumstances. I though I’d share a few thoughts from my experience — as well as what I’ve gleaned from talking to other pilots.

New Pilots

New pilots are mostly interested in doing one thing: building time.

Until they get enough experience as pilots, they’re not able to get a “real” flying job. Instead, they’re usually forced to take jobs as flight instructors, which most of them don’t really want to do. That’s the most common way for new pilots to build the 1,000 hours or more of pilot-in-command (PIC) time that’s usually required to get a non-training job.

This is an unfortunate time for any new pilot who doesn’t have the “right stuff” to be hired by a flight school. What is that right stuff? Flying skills, good attitude, patience, and a body weight under 180 pounds come to mind. Luck is part of it, too. Despite what flight schools tell their students, they can’t hire all graduates of their training program to be flight instructors. Sometimes new pilots need to be lucky enough to get their certified flight instructor (CFI) certificate just when one or more instructors are moving on to their first flying jobs.

For those new pilots who can’t secure a flight instructor job, things can be tough. They can’t get a job and move forward in their careers until they build time and they can’t build time without getting a job. Catch 22. These are the guys who will take any opportunity to fly, no matter what kind of flying it is, even if they have to pay for that flight time. I’ve had at least ten new pilots fly with me on long cross-country flights in my R44, paying an hourly rate much lower than what it would cost them to rent a helicopter, just to build time. There used to be a guy in Southern California who sold time in his JetRanger while he conducted traffic flights. (Is he still doing that?) And then there a few questionable operators who “hire” low time pilots to fly for them, requiring these “employees” to pay at least part of the helicopter’s operating cost when they fly.

No, I’m not interested in having a 300-hour pilot who can’t/won’t get a job as a CFI hovering at treetop level over cherry trees in my helicopter — even if he doesn’t want to be paid.

And don’t get me started on operators who use low-time pilots for potentially dangerous flying jobs, with that flight time as their only compensation. Every year I get at least one pilot calling or emailing me, offering to do cherry drying flights for free. My point of view on this: a professional should be compensated with money for his work, no matter what he does, and responsible operators should be hiring — and paying — sufficiently experienced pilots for the type of flying that needs to be done.

Time building is everything for new pilots — as it should be. Experience is vitally important for safety. And no matter how good a 300-hour pilot thinks he can fly, he’s nowhere near as good or safe as most 1,000-hour pilots.

Experienced Commercial Pilots

Once a pilot has gotten past the time-building stage and is able to qualify for a flying job, his main concern is — or should be — finding the right job. That should meet one (or all) of three criteria:

- Be the kind of flying the pilot wants to do.

- Give the pilot the flying experience he needs to get a future job doing the kind of flying he wants to do.

- Pay a living wage — or better.

In other words, an experienced pilot’s main motivation is the advancement of his career down the path he prefers.

For example, someone interested in EMT work will need turbine flying experience, as well as night flying experience. He may have gotten night experience as a CFI doing all those night cross country flights with student pilots on board, but he likely didn’t get turbine time. A tour job at the Grand Canyon or in Alaska might be a good start. Those jobs are a good start for other kinds of helicopter work, including utility work, since some operators also have utility operations and might have a career path with training right into those jobs.

I want to point out here that those $80K/year helicopter pilot jobs do exist. They just don’t exist right out of flight school. If your flight school lured you in with promises of a big paycheck doing a cool job, they did you a disservice. Different types of flying pay different rates, but they all require a lot of experience to reach the higher pay levels. If your primary motivation is making a lot of money, you’re probably in the wrong career.

The more experience a pilot has, the more opportunities he has. And I’m not just talking about flight time, either. While logged PIC time is important, having a lot of time doesn’t automatically make a pilot qualified for a specific job. For example, I’ve got about 3200 hours of flight time logged, but I could never expect to walk right into an EMT job since I have limited turbine time and very little night flying time. But I could qualify for a job as a heli-skiing pilot because of my extensive experience in high density altitudes and off-airport landings. At this point in a pilot’s career, PIC time and experience, although related, are not of equal value.

So once a pilot has paid his dues and can start getting the jobs he wants, he’s mostly motivated to do the kind of flying he wants to do or that will help him further his career goals and earn a decent living.

Owner/Operator

And that brings us to where I am today and why I didn’t mind spending 40 hours traveling to and from and waiting around in California this week without turning a blade.

Owner/Operators are motivated primarily by one thing: making enough money to keep their helicopters, stay in business, and make a profit — often in that order.

In 2006, when I started seeing a decline in my writing income after riding a wave since 1998, I began to realize that if I didn’t keep my business in the black, I’d have to give up my hobby-turned-part-time-business. As the situation got worse, it changed the way I operated my aircraft. The ratio of non-revenue to revenue flight hours dramatically decreased as I flew more for hire and less for fun. While I still wanted to fly as much as I could — after all, I got into this business because I love to fly — money became my primary motivator.

Think about it: why would I let other pilots fly my aircraft if I love to fly? Because I was getting compensated for that flight time. That compensation would go toward paying my aircraft expenses.

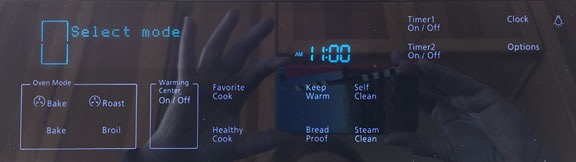

Here’s my company’s most valuable asset on Wednesday, parked in California, waiting to be flown. A smart owner/operator will find ways to earn money without turning a blade.

As my Alaska Air flight descends into Seattle, I think about the chain of events that led me to seat 9A today: getting a frost control contract in December with a start date in March, repositioning the helicopter to California in late February (with another pilot at the controls), spending a few days on standby for an early contract start date before returning home. Then a phone call at 3:22 PM on Tuesday followed by a scramble to book and catch a flight to Sacramento, two nights on standby, another call to release me from standby, and a trip to Sacramento airport to catch this flight. Along the way, there were rental car reservations, hotel stays, and meals. I preflighted the helicopter once and woke up long before dawn both days.

And I didn’t turn a blade.

But I’m happy. No, I’m thrilled. Why? Because without putting any wear and tear on my company’s most valuable asset — my helicopter — I netted more money in less than 40 hours than I did during the period of from October through January. More than most new pilots make in a month.

Some people might think this is a great deal — after all, I’m making money without doing anything except traveling and waiting around. But these people are missing the big picture. I paid $346K plus interest to buy my helicopter. It costs more than $20K a year to insure it and keep it airworthy. Shouldn’t that enormous investment not only pay for itself but earn a profit? Every opportunity it can?

And, sadly, that’s what’s most important these days for me: keeping my bottom line healthy enough to keep flying for a living. That’s what’s on the minds of most owner/operators who aren’t independently wealthy.

Respect that — and don’t expect handouts.

Think About It

So here are three different ways three different pilots might look at what’s important to them about flying.

Why bring this up? Mostly so that pilots on each rung of the career ladder can better understand what’s motivating the other pilots.

I think about the new pilots and how eager they are to build time at almost any cost. I think about the more experienced pilots who are willing to be picky about the jobs they take just so they get set on a career path that’s right for them. And I think about owner/operators who have a helicopter at their disposal all the time but must responsibly choose how to deploy that asset for maximum returns.

I want the folks just starting to climb that ladder to understand the rest of us — and realize how their priorities will change if they slip into our positions some day.