Here’s how it happened and how it is three weeks later.

I didn’t blog about this when it happened. It may have been embarrassment. Or it may have been because my life got very busy for a while with house guests and day trips and life in general.

It was on Monday, August 5. I’d spent much of the day — the third or fourth day in a row — out at my future homesite in Malaga, clearing out invasive weeds along the driveway and the road in front of my house. It was hot, exhausting work, but I felt good at the end of each day. Like I was working toward a goal. (Am I the only person who feels that way while making progress on a project?)

That particular day, I’d been using a gas-powered hedge trimmer to cut weeds. I’d rented it from Home Depot. The tool did the job, but not as easily as I’d hoped. And it was a bitch to get started. I returned it that afternoon, contemplating the purchase of a chainsaw again.

On the way home — it was probably about 5 PM at the time — I stopped at the supermarket to buy groceries. Because I had so much junk in the truck I did something I very rarely do: I put the 5 or 6 grocery bags in the truck’s bed.

That was my mistake.

When I got home, I discovered that the grocery bags had shifted around in the back of the truck. So I lowered the tailgate and climbed up to gather them together. They were the usual plastic shopping bags and I grasped them by their handles with four in one hand and two in the other. I walked to the back of the truck, stood on the edge of the tailgate and crouched down with my butt about four inches off the tailgate. I put my right hand down on the tailgate and launched my feet off the back of the truck.

Keep in mind that this little jumping maneuver is something I do regularly. The distance to the ground is only about 3 feet. By crouching and launching like that, I minimize the impact of the landing. I do it all the time. I’ve never had a problem.

Except that Monday. As I launched my feet off, one of my feet — maybe my right? — got hung up on the rough surface of the spray-in bed liner. It could have been because I was tired from a full day at work, but it was more likely complacency — not thinking about what I was doing because I had done it so many times before. I didn’t make a clean jump. I realized this as I was falling and tried to recover.

I don’t know exactly how I landed, but I suspect my left foot took most of the impact on an angle. My left knee and the palms of both hands hit the gravel next. The grocery bags crashed all around me.

I immediately thought of the Tito’s vodka and Maker’s Mark bourbon what were in the bags. It would be a real shame to break the bottles of $50 worth of liquor.

But pain interrupted those thoughts. Lots of pain. I was hurting badly. I rolled over on my back and began taking inventory on body parts. One by one they checked in OK. Except my left foot. That was just registering pain.

I sat up and gathered the bags together. Neither bottle had broken. Whew!

I sat for a moment more. My left knee was bleeding but the palms of my hands were fine. That could have been worse, I thought to myself.

It was. When I tried to stand up, I realized I couldn’t put any weight on my left foot.

Oddly enough, I didn’t think much of the problem at first. After all, we’ve all gotten hurt in silly little accidents and after the initial shock wears off, everything works fine. I figured that my foot or ankle — whatever was sending those pain messages to my brain — was just whining a bit longer than usual.

In the meantime, it was hot and I was thirsty. I managed to get to my feet and sort of hop over to my RV. My porch was a bit of a challenge and I honestly don’t remember how I got up the stairs. I put down the bags of groceries and poured myself a glass of lemonade with lots of ice. I drank it all and refilled it.

My ankle was still sending those pain messages. What was up with that?

I sat down on the steps that lead up to my bedroom and pulled off my shoe. My foot seemed to explode into a swollen mass. I couldn’t move my toes.

This was not good. There was a chance, I realized, that I may have actually broken something.

I pulled out my phone and called my friend Kathryn, who lives in the orchard.

“What are you doing?” I asked once the greetings were over.

“Nothing much,” she replied. “Just hanging around, enjoying the weather.”

“Could you do me a favor?” I asked.

“Sure. What do you need?”

“Could you drive me to the hospital? I think I might have broken my ankle.”

The tone of the conversation changed immediately to once of concern and urgency. A few minutes later, Kathryn and her husband Donn were out in front of my trailer with their truck. I used a stepladder as a cane to meet them on the driveway and managed to climb aboard.

They took me to a local clinic, which they thought would be faster than a hospital. Donn fetched a wheelchair and wheeled me in. I did the paperwork at the desk. And then they waited 90 minutes with me. (I have such great friends.) Kathryn came into the examining room with me to keep me company. I was x-rayed, poked, and prodded. It was pretty obvious that the problem was in my foot — not my ankle. The verdict came from the nurse practitioner who’d been assigned to me.

“It’s not broken. It’s a sprain.”

“That’s good,” I said, relieved.

“No, it’s not,” she corrected me. “For people over 40, sprains are usually worse than breaks. They take longer to heal.”

She wrapped me up with an ace bandage, gave me a prescription for pain meds, and told me where to find crutches at 7:30 on a Monday evening. She also gave me a sheet with the standard RICE advice.

My friends took me to Fred Meyer. Kathryn went in and returned with a set of crutches. Then we went to Olive Garden for dinner (their choice). I had a terrible drink and an excellent meal, which I only ate half of. By the time I got home, it was after 9 PM. I was glad I’d remembered to put away the yogurt before leaving.

The day after my mishap was spent in bed with my foot elevated. But it swelled up anyway.

In the morning, I was amazed by how bad my foot looked. I took a picture and put it on Facebook. I spent much of the day in bed, trying hard to keep my foot elevated above the level of my heart.

Do you know how hard it is for me to sit still when I have things to do? It was a miserable day.

The next day, I had things to do and I wasn’t going to let my swollen foot stop me. So I wrapped it up grabbed the crutches, and got on with my life.

Of course, during this time I was still on contract for cherry drying. I had some concern over whether I’d be physically able to fly. After all, flying a helicopter requires four limbs, preferably healthy ones. But I put those concerns to rest on Wednesday when I fired up my helicopter and flew it down to Wenatchee for some scheduled maintenance. Fortunately, my helicopter doesn’t require much pressure on the pedals.

I admit I didn’t follow the RICE advice to the letter. Although I slept — or tried to sleep — with my foot elevated on two pillows, I didn’t ice it as often as I was supposed to and I certainly didn’t rest it very much. I was on two crutches for just two days and then just one crutch for a week. After the first week or so, I realized that it looked almost normal when I got out of bed but swelled up to epic proportions within a hour of being up and around. The swelling included my foot and ankle — indeed, I had a chankle. I ditched the crutches entirely about 10 days after my mishap. That’s when I flew my helicopter to Seattle to pick up a friend and did the tourist thing around Pike Place Market and the Space Needle. It was pretty swollen that night.

I’ve turned down five invitations from friends to go hiking. You have no idea how frustrating that is.

But I’ve also been out on my boat three times. Not much walking involved there. Once, while fishing, I sat on the swimming platform and dangled my feet into the Wenatchee River. The nice, cool water was soothing.

I’m now starting week 4 of healing. I’ve found a good compromise. When I prepare to go out for the day, I wrap my foot firmly in the ace bandage, put a sock over it, and put on my good walking shoes — ironically, the same ones I was wearing when the mishap occurred. The shoe gives my foot the support it needs; it only hurts when I step on uneven surfaces. Because the flexing motion of walking also causes pain, I have a pronounced limp when I try to walk quickly. But around my home, it’s not that bad. Yesterday, when I unwrapped it, it didn’t even look very swollen.

If I behave myself and stay off the hiking trails, I’m pretty sure I’ll be 100% healed by the end of September. That’s a long time, but I just have to deal with it.

As for jumping off the back of my truck — well, I think this little incident has reminded me that I’m not 22 anymore. We’ll see if I remember this lesson in the months and years to come.

There’s an excellent cheese shop not far from where I live: The Cheesemonger in Leavenworth. It — and the smoked meat house called Cured — is the only reason I go to that tourist town. I go early in the day, before the crowds arrive. I prefer taking my motorcycle, since there’s always motorcycle parking right outside Cured. I descend into the basement shop, make my way past the milling tourists nibbling on samples of cheddar and swiss, and find one of the many helpful counter people. Then I place my order, rattling off the names of the cheeses I like best: triple cream brie, morbier, butter cheese, and whatever blue-veined cheese behind the glass catches my eye. I whisper the secret password to get my local discount on checkout, leave a tip, and climb back out into the sunlight while the same milling tourists stand uncertain on how to proceed. In and out in a flash.

There’s an excellent cheese shop not far from where I live: The Cheesemonger in Leavenworth. It — and the smoked meat house called Cured — is the only reason I go to that tourist town. I go early in the day, before the crowds arrive. I prefer taking my motorcycle, since there’s always motorcycle parking right outside Cured. I descend into the basement shop, make my way past the milling tourists nibbling on samples of cheddar and swiss, and find one of the many helpful counter people. Then I place my order, rattling off the names of the cheeses I like best: triple cream brie, morbier, butter cheese, and whatever blue-veined cheese behind the glass catches my eye. I whisper the secret password to get my local discount on checkout, leave a tip, and climb back out into the sunlight while the same milling tourists stand uncertain on how to proceed. In and out in a flash.

Temporary power is what’s commonly installed at a construction site to provide power to the builders for their tools. It consists of a 4×4 post with a circuit box, meter, and outlets. Chelan County is very specific about how the box should be installed. It’s all detailed in their 74-page book, Residential Electrical Services Connection and General Information,” which is available as a

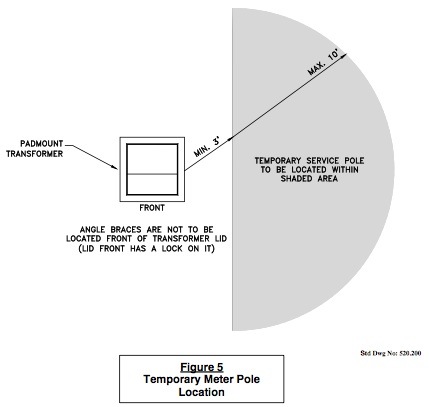

Temporary power is what’s commonly installed at a construction site to provide power to the builders for their tools. It consists of a 4×4 post with a circuit box, meter, and outlets. Chelan County is very specific about how the box should be installed. It’s all detailed in their 74-page book, Residential Electrical Services Connection and General Information,” which is available as a  You see, the power pole has to be 3 to 10 feet from the transformer, which is already on the property. So I’m limited as to where I can put the pole. Fortunately, the transformer and pole location will be quite close to the building site. That’s good because the building must be within 100 feet of the transformer. So I’m all set for that.

You see, the power pole has to be 3 to 10 feet from the transformer, which is already on the property. So I’m limited as to where I can put the pole. Fortunately, the transformer and pole location will be quite close to the building site. That’s good because the building must be within 100 feet of the transformer. So I’m all set for that.

Here’s the finished trench and hole, approved by my tiny inspector.

Here’s the finished trench and hole, approved by my tiny inspector.