Your questions, answered in one place.

Since I began blogging day-by-day construction progress of my new home on May 20, 2014, I’ve gotten a lot of questions and comments from blog readers, Twitter followers, and Facebook friends and followers. I thought I’d respond to a few of the most common ones here.

“Not much in the way of foundations. Small wonder whole towns disappear when tornadoes hit.”

The long posts were hoisted with a crane.

This comment appeared on the blog post for Day 2, which showed the posts supporting the building in place. News flash: there is no traditional “foundation” and there won’t be.

I’ve repeatedly linked to a Wikipedia article about pole buildings in an attempt to educate readers about this type of construction. Unfortunately, the ability to consume web content beyond looking at pictures and video remains above the skill level of many blog visitors.

The posts supporting my building are 6×8 or 8×8 (depending on length and position). Each pole is sunk 3 feet into a hole 4 feet deep and 3 feet across. The holes and post placement were inspected by the county literally minutes before the concrete trucks arrived to fill each hole with concrete.

As far as tornadoes go, the chances of a tornado barreling down a path along the base of the cliffs in Malaga, WA are pretty slim. So slim, in fact, that you stand a better chance of winning a lottery jackpot, being struck by lightning, and being attacked by a shark — all in the same day.

But just in case it does get windy, the building is designed to withstand gale force winds. I don’t recall the exact number, but I do remember it being over 100 miles per hour.

And if you’re worried about seismic activity when Mount Rainier turns Seattle into an ash-covered scene from a futuristic disaster film, it’s also built to withstand earthquakes — not that we’ve had any serious ones here in a very, very long time.

Where’s the foundation?

See above.

When are they going to pour the foundation?

See above.

Please tell me they’re going to pour a concrete slab.

They’re going to pour a concrete slab.

Really. They are.

For some reason, they do this after the building has been constructed. I don’t know why. Maybe it’s so they can drive equipment around inside without worries about damaging new concrete. Does it really matter? The building is not attached to a foundation or a slab so it doesn’t really matter when they pour it. For some pole buildings, they don’t pour a concrete slab at all. In fact, I could save a bunch of money now by putting off the pouring of my slab until I’ve got some more cash. And believe me, I’ve been thinking about that for the garage side, which really doesn’t need concrete right away.

My building will also have a floor drain in the RV garage. That’ll make it possible to do something silly — like wash my car or helicopter inside. (Imagine that!) Or for the building to someday be used as a wine-making facility. (That’s thinking ahead.) The concrete in the RV garage/shop side will be gently sloped to that drain; the concrete in the car garage side will be gently sloped toward the garage doors.

I’ve got it covered, folks.

Who designed the building? Did you work with an architect?

I designed the building. I did not work with an architect.

This probably saved me about $10K in design fees.

It’s also one of the reasons I went with a pole building. Not only is it simple construction, but the folks who specialize in pole buildings can make whatever you dream up a reality without getting costly third parties involved. I brought my sketches to Western Ranch Buildings and Tanya patiently worked with me to fine-tune them for cost effectiveness without sacrificing my must-have features — such as the windows and huge RV garage door. Tanya, working with an in-house engineer for some components, drew up plans that would satisfy the county and give the workers something to work with. If you saw how simple my building plans are, you’d be shocked.

As for the design itself, I thought about what I needed in the building — space for all of my possessions and a modest living area. Then I thought about what I wanted in the building — a shop area, windows to let in light and air and show off the views from inside, decks to take in the views from outside. I knew I wanted that living space on the second floor and I knew it had to face the views. Since the RV garage side needed to be tall to accommodate my RV and helicopter, the living space had to be over the regular garage. I went with a four-car garage because that’s what fit in the 24 x 48 foot space I limited the living space above to.

(County ordinances allow me to have two homes on my 10 acres, as long as one of them is under 1,200 square feet. Since I can’t afford to build a garage and a home, I’m building the 1,200 square foot living space first and leaving the prime building location available for the construction of a real home, likely by the property’s next owner. When I had the septic system installed, I ran lines for both building sites, so the next owner will be all set to build that dream house.)

In a way, the design emerged on its own. Sketches evolved. The original design was a huge square building with a standard peaked roof. But when my neighbor put in a split roof, I realized that it would not only look better but also give me another interior wall for windows into my living space. I changed my sketches accordingly and the final design took shape.

Everything I did was well thought out — hell, I had enough time to think about it — with plenty of consideration for future needs — even a future beyond my ownership.

Why aren’t the builders doing the interior of your living space, too?

Two reasons.

One is that these folks specialize in pole buildings. Although they can do interiors, it’s not what they usually do. Not only that, but they’re very busy and I really can’t delay this project any more than it has been delayed. (I’m sick of living in a trailer and want a solid roof over my head, preferably one that doesn’t sway when the wind blows.)

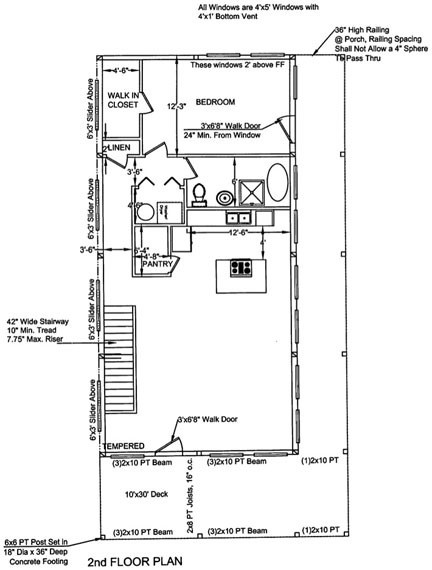

Here’s the living space floor plan as submitted to the county. It’s not 100% right, but it’s close enough for permitting purposes and to get bids on HVAC, framing, insulation, and drywall.

The other more important reason is money. I’m not quite sure what I can afford to get done. I know I can pay for the shell of the building; I’ve been saving for well over a year, living on the cheap in my RV to put aside every penny I can. The income I get from this season’s cherry drying work and the promise of a loan from a family member if I need it assures the shell will be done.

I’m not sure, however, how far I can stretch my money beyond that. I know I can save money by doing things myself; I have every intention of doing all the plumbing and electrical work, for example, and will likely do the floors and all the painting. But I also know that I need to hire professionals to do difficult things such as HVAC ductwork, framing, and drywall. By breaking down the living space project into sub-projects, I can do them one at a time, knocking them off as time and money allows.

With luck, heavy rain over the next few months, and a lot of hard work, I’ll be cooking up Thanksgiving dinner for friends in my new kitchen.

Can you share a conceptual drawing of what it will look like when done?

This question from a Facebook friend made me giggle. You see, they’re working so very quickly.

My response: If you wait two weeks, I’ll have a photograph.