As if I didn’t have enough hobbies to keep me out of trouble.

I’m in Quartzsite, AZ, this January and although I originally had plans to camp out in the desert for the first half of the month, a variety of circumstances convinced me to take a booth at Tyson Wells’ Rock and Gem show. I’m selling (or trying to sell) aerial photos of desert campsites. (More on that in another post.) The east side of the show is full of rock vendors, many of which sell polished cabochons (or “cabs”) and finished jewelry.

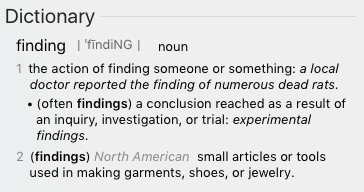

In case you’ve never seen the word “findings” used this way, check definition 2 here.

There are several ways to make a rock into a piece of jewelry. The most obvious is to drill a hole in it to fasten a hoop or use some other sort of findings. But a more artistic method is to use wire to wrap the stone securely and add embellishments. This is called wire-wrapping and there are a lot of examples of it here, especially during the rock shows at Tyson Wells and the bigger/better rock show at Desert Gardens nearby.

Kindling an Interest

Last year, my friend Rebecca came to town while I was here and introduced me to her friend John Heusler, a gemologist who has a booth each year at Desert Gardens. John not only cuts and polishes stones, but also makes jewelry. Dorothy Roubik-Ellenbecker, another jewelry maker, works for/with John and shares booth space. She makes beautiful wire-wrapped pieces with intricate wraps that are really a joy to behold.

I got slightly interested in wire-wrapped jewelry last year, but was busy doing a lot of other things. This year, I’m sort of trapped in my booth, especially on weekends when there’s a decent crowd at the show. I’ve been looking at a lot of different wrapped jewelry styles while I’m here and starting getting the idea that maybe making some of these was within my capabilities.

Getting Training

I talked to Dorothy and asked if she’d be interested in teaching me in the evening, when we’re both done booth sitting for the day. She agreed and set a date for Monday evening. I asked about books that might be helpful and she recommended skipping the books and going right to YouTube. So I did.

I discovered that there are a lot of how-to videos on YouTube about wire-wrapped jewelry. Search for yourself. I spent one evening watching about a half dozen of them, mostly by one artist. “Tried-and-Tested Wire-Wrapping Tutorial for Pendants” showed one basic technique and “Quick Wrap! Wire Wrapping Tutorial for Pendants” showed a quicker but less polished technique. Neither of them looked terribly difficult. I went to bed that night eager to get started.

Buying Materials and Tools

Fortunately, everything I needed was walking distance from my booth. Before I opened that morning, I went shopping for cabs. I bought two nice ones, then realized that since I was just learning, I should start with lesser stones. I found a booth selling some nice but apparently low quality ones for a lot less. I bought ten.

I closed up early (as I often do — seriously, how to people do 9 to 5 unless they’re busy the whole time?) and walked over to the booth where I could find tools and wire. Although the woman working there tried hard to sell me expensive square silver wire, I homed right into the silver-plated copper. I expected to make a lot of mistakes and didn’t want to screw up with expensive wire.

If you look at the two videos I linked to above, you’ll see that the woman who does the tutorials makes a point of saying that she uses regular tools — not special jewelry tools. Sure, you can use an Ace Hardware needle nose pliers and wire cutter to get the job done. But look closely at her work. Those ridges that make needle nose pliers so good for gripping also mark up the soft metal wire she uses to wrap the stones. I didn’t want those ridges on my stones so I bought the right tools.

Her husband was extremely helpful with the tools. They had a big selection with a variety of qualities. One video I watched discussed tools in some detail, so I knew what I needed to get started. He helped me find every one of them, including one that wasn’t displayed that he had to dig through stock to find. (He also recommended another tool, which I passed on but wound up buying the next day.) The tools weren’t expensive — they averaged $5 to $10 each. My initial investment in tools and wire was $35, which I didn’t think was bad.

In case you’re wondering what I bought, here’s a list:

- Small chain pliers

- Small flat pliers

- Small round pliers

- Wire straightener

- Wire cutter

- 18 gauge silver plated copper wire

- 20 gauge silver plated copper wire

- 22 gauge copper wire

First Tries

That evening, after dinner, I spread out my tools, pulled out some wire and a large teardrop-shaped labradorite cab, and got to work. I went with the quick wrapping technique in the second video I linked to above, using the 20 gauge silver wire. The biggest challenge was holding the cab and wire in place while I did the wire twisting required to hold it. I was almost surprised when I got the cab to stay in the cage I’d built for it. I then made and positioned swirls on the front of the piece with two of the leftover ends. I admit that I was kind of blown away by the results. The finished piece didn’t have the same polish as John or Dorothy’s work, but it sure wasn’t bad for a first try.

My first finished piece: labradorite wrapped in silver-plated copper.

A closer look at the piece, however, reveals its problems. The biggest problem, in my opinion, were the small burrs I’d created in the wire by rough handling. Simply said, I’d used my flat pliers too aggressively and had damaged the soft metal wire. There were burrs on the decorative bends, especially on the back. This could catch on fine fabrics like silk or nylon, making the piece pretty much unwearable. Unless Dorothy knew a way to fix it, it would never be more than a piece for show.

My wire twists aren’t as neat as they could be, either. Although my spirals are very good with minimal tool marks, the wire joins are clumsy. Surely Dorothy would have tips to fix that, too.

I decided to try the more difficult technique on a small piece of bacon agate that the vendor in the next booth had polished up and given me the day I arrived. I really think that the desire to do something useful with this pretty little stone is what helped fuel my interest in wrapping.

My second piece was a small bacon agate stone gifted to me that I wrapped in copper.

I chose the thinner, 22 gauge copper wire for the job. I thought (rightly, I believe) that the copper wire would go well with the colors in the rock and the small size of the rock meant I needed a thin wire. I followed the instructions in the video to the letter to create the tightly wrapped anchor points that would form the cage around the rock. I was very careful to avoid overworking the metal; this was a piece I wanted to wear and I didn’t want burrs. I purposely made the bail small and loose and added a single swirl to the front. When I was finished, I was very pleased with my work.

I sent photos to a few friends and put them on Twitter. I got some positive feedback, which made me feel good.

I watched a few more videos before I went to bed.

Additional Efforts

The next morning, I went back to the tool shop and bought three more tools:

- “Micro” chain pliers – to get into tighter places

- Nylon headed flat pliers – to prevent marring soft metal

- Bailing pliers – to make nice bends

My third piece was an oval of some sort of speckled agate wrapped in silver-plated copper.

I chose another cab from my collection of cheap ones: an oval stone that combines a white quartz with black and pink rock specks. (No one seems able to give me the exact name for this stone, but I will keep trying to find out.) Again, I went with the more polished technique that used tightly wrapped anchor points to build the cage. I ended up with spirals that I positioned over the area that had no colored specks. I think it came out good, although I wish I’d made the upper spiral a little larger.

I had a nice elongated piece of rose quartz that was actually two-sided and decided to get fancy. I’d do a bevel mount with a thin wire to weave the bevel and hold the stone. I walked over to the findings booth and bought two more types of wire for my quickly growing collection:

- 24 gauge silver plated copper wire (for this piece)

- 28 gauge copper wire (for future use)

Then I went back to my booth and got to work. I started off well, using the 18 gauge silver-plated copper wire for the edges of the bevel. When I brought the ends up and around, I created a really pretty spiral finish.

Around this time, a woman I’d seen around the show came by my booth. She was on a bicycle with a small, white, curly-haired dog in the front basket. She’d caught sight of me working on the wire wrap as I sat at the table in my booth. She also does wire work. I told her I’d just started and showed her my pieces. (By that time, I’d also bought a small glass-fronted box to hold and display my work.)

We chatted for about 45 minutes. She complemented me on my work, pointing out how nicely I’d used the swirls to fill the white space on the stone with the pink and black speckles. She said that the labradorite piece I’d chosen was not a good one, showed me how to look for features in labradorite, and explained the importance of finding good stones by “cherry picking” them. She told me about a big booth on the other side of the show that had decent quality, inexpensive cabs, as well as where to find more wire in a shop in town. She pointed out that the swirls in one piece could move if they were caught on the wearer’s clothing and gave me a tip about preventing that. She also told me about some inexpensive wire-wrapping classes being held evenings at the QIA building not far away.

While we talked, I tried to work on the piece. The distraction is probably what screwed it up — I accidentally shifted one of the thick wire frames while trying to weave it to the opposite side. My wraps were okay — neither good nor bad — but I’d made one side much smaller than the other, thus screwing up the bevel.

I had to run out to the post office so I closed my booth early. On the way back, I stopped at Hardies Beads and Jewelry in town. They sell mostly beads and jewelry (as you might expect) but do have a good selection of wire-wrapping wire at the back of the store. I wound up spending about $32 on a selection of wires in colors and styles, including an interesting 21 gauge twisted silver wire and various thicknesses of antique copper wire. I now had just about all the wire I’d need to move forward with additional projects.

My fourth piece was an incredibly boring round piece of rose quartz that I dressed up with fancy twisted silver-plated copper wire.

That evening, I tried to fix the bevel piece but failed miserably. I took a few photos of the design (which I won’t share here) so I could remember what I liked about it, then took it apart. I tried two other wraps on that stone and gave up before putting much time into it. But rather than finish the day with a failure, I picked a round rose quartz piece and did a wrap on that using the new twisted silver wire with a narrower wire for the wrap points. The stone was extremely boring — I honestly don’t know why I picked it — but the fancy wire and swirls I added really dressed it up a bit.

So at this point, I have four completed pieces, three of which can be worn.

Next Steps

It’s Saturday morning. Before I open my booth for the day, I’ll stop by that shop with inexpensive cabs and buy a few interesting ones. I feel better qualified to choose them now that I know how I can work the features of the stone into my work.

After I open my booth, I’ll settle down with my little bin of cabs and tools and wire. I’ll pick out a cab and work up another piece. And maybe another after that.

And I’ll likely do a few others on Sunday.

On Monday evening, I’ll bring my collection to Dorothy for her critiquing. I hope she’ll be honest and frank. I also hope she can offer good advice on doing the wraps and twists I find difficult. And teach me how to do bevels!

It might take more than one evening. That’s fine. I’ve told her I’ll pay for her time, although I don’t think she expected that. (She is a professional; she should be compensated when sharing her expertise with a novice.) We’ll both be here at least until January 25, so we have time for a few lessons. I’ll post an update on my progress — if I make any!

Discover more from An Eclectic Mind

Subscribe to get the latest posts sent to your email.

I’m guessing that wiring ‘cabs’, like auto-rotations, or greaser landings, improve with experience..

I really like the bacon agate in the copper wire, it has a sort of Aztec feel and the stone has ‘presence’.

My only observation is that the top linkage of all the wires looks a little undefined and uncertain. An engineer would crimp these wandering wires off with a band of matching metal and resolve them with a single simple loop for a chain/ thread; that would concentrate the observer’s mind on the decorative features of the piece…

Good work.

Thanks very much. The Bacon Agate piece is my favorite, too. And I do agree that I need work making the pieces look more finished. The two I did yesterday are better. More photos to come in the update.

Agree about the bacon agate. And actually about the loops at the top as well.

But, more importantly, I am so impressed by how you pursue things and how down to earth you are.

Thanks, Barbara.

Don’t be so impressed! I get bored easily and am always interested in learning new things. I seem to have a lot of time on my hands — one of the benefits of not having to share my time with a greedy partner — and I’ve been spending it on more artistic endeavors lately.

What I really should be doing is writing…

Go for it I started out making pieces just like the ones you made and within a year I was doing multi layered woven pieces that I had once thought I’d never be able to do!! Check out what I have done at alittlebittwizted on Facebook and then check out “Go Art Yourself” on YouTube and Nicole Hanna on Facebook (same person) she’s an amazing teacher and she is really helpful to new artists too ❤ good luck in your new hobby I can’t wait to see how fast you evolve as a wire wrapper

It’s gone way beyond a hobby. The post you’re commenting on is two years old and I’ve turned jewelry making into a side business. It now accounts for about 15% of my total income. I sell on Etsy, in several galleries and shops, and at art shows in Washington, Arizona, and California.

I don’t do woven wire pieces; I’ve never really liked that style. I like to minimize the wire work to emphasize the beauty of the stones. That’s why I try to buy (and polish myself; I do some lapidary work) really nice stones — when you’re covering them with wire it really doesn’t matter what they look like.

I’m actually evolving away from wire work and into more silversmithing these days. Sadly — as you might be aware — wire wrapping has a bit of a bad reputation in art show circles. There’s so much bad wire wrapping out there that as soon as a jury sees wire work, they reject it out of hand. I’ve even seen art show descriptions written to exclude jewelry made with wire. I’ve had some success with my work and can get into most of the juried shows I apply to, but I realize that I need to step up and move beyond working with wire. A recent update to my Etsy shop shows off some of my newer efforts: https://www.etsy.com/shop/MLGemstones

I’m hoping to expand my YouTube channel this spring and summer with some how-to videos. I’ll be posting about it here when there’s something worth seeing.

Thanks for visiting! Good luck with your work!

Nicely done. I was taught to use a popsicle stick or a wooden dowel to rub smooth your burrs from your pliers. Make sure the cabs you get are high polished with no obvious scratches on the surface. If you do get one like that, either rehab the surface yourself, or take it to your local gem and mineral club’s shop and one of the lapidary instructors should be happy to polish up your cab. Keep up the great work!!