I’m not convinced it’s evil — well, not all of it — but I’m getting more and more convinced that it’s dumb for some sellers.

I’ll start by saying this: I hate traffic. Now I know that everyone hates traffic — nothing is worse than bumper-to-bumper stop-and-go on a freeway — but I even hate local traffic, the kind usually created by traffic lights and made worse by construction or too many vehicles on the road.

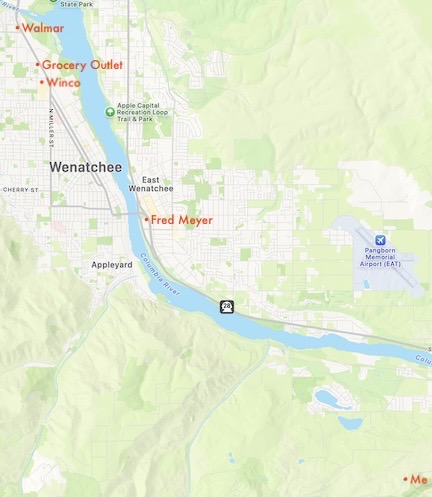

Some of the shopping options in my area. This isn’t all of them. There are also two Safeways, an Albertson’s, at least one other Grocery Outlet, and a Costco (which I am not a member of).

It’s for this reason that I do my grocery shopping at Fred Meyer, which I can get to by making a right turn at just one traffic light and not hit any other traffic. It’s exactly 10 miles from my house and is the closest supermarket. But it is definitely not the cheapest. That award would likely go to (in no particular order) Walmart, Grocery Outlet, and Winco, where some of my neighbors shop. I generally do not shop there because of the traffic I have to deal with on my way there and back. I know there’s traffic because I hit traffic at 7:30 AM Thursday when I had to go to Walmart. (More on that in a moment.)

So this explains why I prefer Fred Meyer, even though I know that if it weren’t for coupons that come in the mail and digital deals on the app I would definitely be paying a premium for my groceries. (For the record, though, I don’t like the attitude of the cashiers at Winco (which also does not accept credit cards) and Grocery Outlet seems pretty skeevy sometimes.)

But I had two online shopping experiences this week that have gotten me thinking more about shopping online for things other than groceries that I can buy locally.

Continue reading →