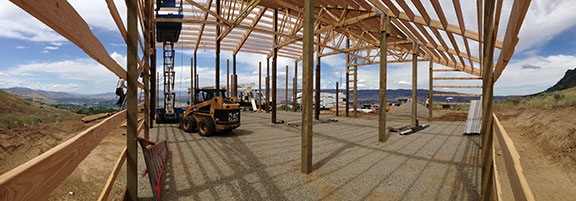

Interior is starting to come together.

My building will have a second floor over a four-car garage. This 24 x 48 foot space will be my home.

The builders who have been working on my place for the past two and a half weeks are providing a shell — an enclosed but otherwise empty space. The only things they’re doing for the upstairs living space are providing an unfinished (plywood) floor and stairs. They’ll also be installing the windows and doors, and providing the basic framing (but not the floor) for my deck space.

Once the floor is in place, I can begin getting bids from contractors to do the interior framing — in other words, build the interior structure of that living space. The framing needs to be done before I can move in and install the plumbing and electrical systems. So the completion of the second floor’s floor and stairs are a key milestone for moving forward with my living space.

Yesterday, they began work on the second story floor by installing two very thick laminated beams and then hanging the framing between them.

The second floor will be supported by a series of laminated beams like this one.

The beam sits atop a 4×6 post on either end.

The laminated beams come from the lumber supplier a bit too long for the job. The workers had to trim them to size. The scrap piece from one of them is a serious block of wood that, with a little work, would make a nice butcher-block table. I’m thinking of fixing it up for just that purpose, perhaps for the east deck where I plan to put my BBQ grills.

Here’s where they left off on Day 9.

Framing between the two big beams really gives the second floor some structure. I found myself getting really excited, knowing that before the end of the week, I’d be able to walk inside the upstairs space I’d soon be living in.

Angel, the lead worker, told me that Tanya from the office would be by on Tuesday or Wednesday to finalize the locations of each window. Throughout the planning process, windows have been a huge deal and I’m happy that they’re as serious as I am about getting them just right.

The crew also prepped some other beams with hangers, getting a head start on the work they’d do the next day.

Here’s the time-lapse video: