Off to a good start.

The lumber delivery truck pulled into my driveway at 6:15 AM sharp. I was already up. In fact, I was setting up my time-lapse camera on the roof of my RV.

The truck was neatly stacked with lumber. A forklift clung to the back. It didn’t look like enough lumber for a 48 x 60 foot building, but the driver assured me it was. In fact, he told me it was a lot of lumber.

The lumber truck arrived at 6:15 AM. I was awake (of course).

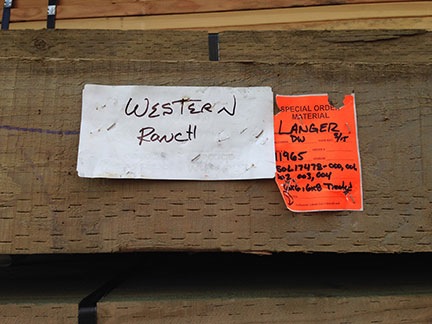

It must be mine. It has my name on it.

He didn’t waste any time offloading it and leaving it spread out on the building site. Then, without taking up my offer of coffee, he backed down the driveway the way he came and was gone.

I looked over the lumber he’d left behind — my lumber. The skeleton of my future home in a sort of kit.

As one of my Twitter friends said about this photo, “Some assembly required.”

The builders showed up less than 20 minutes later. There were 3 hispanic guys who introduced themselves and shook my hand, the owner of the company, and a bobcat with two augers. They spent about an hour moving around the lumber. Then the boss left and the workers got down to work with the auger.

A pole building utilizes post-frame construction. From Wikipedia:

Pole framing or post-frame construction (pole building framing, pole building, pole barn), is a simplified building technique adapted from the labor-intensive traditional timber framing technique. It uses large poles or posts buried in the ground or on a foundation to provide the vertical structural support and girts to provide horizontal support. The method was developed and matured during the 1930s as changes in agricultural practices, including the shift toward engine-powered farm equipment and the demand for cheaper, larger barns and storage areas. Unlike competing building methods, once the poles, girts, and rafters are put in place, much of the construction work on a pole-built structure can be handled by a single individual over the course of a month or season.

My building required 40 holes roughly 3-4 feet in diameter and 4 feet deep. The builder estimated that construction could be completed in 6 to 8 weeks. Of course, that’s just the exterior of the building; I still needed to finish my living space.

Close-up view of one of the augers they used to dig holes for my building.

So that first day was all about digging holes. I was worried about rocks on the south side of the site. I’d been warned that although the pricing included some work with rocks, if there was a lot of rocks and they couldn’t do the digging, I’d have to pay extra for earth moving equipment to come back in and dig the holes. Extra could get into the thousands of dollars. Every extra dollar I spent on the building’s frame was a dollar that wouldn’t be available to finish the living space. Needless to say, I wanted those holes to be easy to dig.

They encountered a rock about three feet down on the first hole. The workers stopped and got tools out of their truck. I came over to watch. Angel, who seemed to be in charge of the workers, told me it didn’t seem to be a big rock. They banged away on it with a digging stick and then dug it out with shovels. And then they got the auger back in place and dug.

They had the same problem with the other south corner. Angel said it wasn’t bad, though.

The workers deal with a rock on the second hole.

And when they moved north, they didn’t hit any rocks. At all.

In fact, of the 40 holes they dug, they only hit rocks on four of them — the four south side holes.

The digging went amazingly fast. I’d estimate about 10 minutes per hole. The auger went in and filled its grooves with earth. Angel moved aside and then rotate the auger in the opposite direction to dump the earth in a pile. He made two of these piles and later used the bobcat to move the earth into my future driveway apron. They took a break for lunch at 11:30 AM. By about 2 PM, they were done with the holes.

Sometime around the middle of the day I emailed Tanya, the woman I’d been working with at the builder, to let her know how it was going. I think she was just as happy as I was that the work was going smoothly.

I had to leave at 3 PM, so I didn’t get a chance to see them finish up. I did watch on the time-lapse, though. After finishing the holes and moving that dirt, they spent the rest of the day moving the posts around. By 4:15 PM, they were gone.

The project is definitely off to a good start. Even today, as I type this, I can’t believe how much they’ve gotten done in less than 90 minutes. A crane is pulling down my driveway right now. You can read about that tomorrow.

In the meantime, here’s yesterday’s time-lapse.