My living space begins to take shape.

Although I plan to do a lot of the interior work on my living space myself, there are a few things I simply can’t do. Framing is one of them.

Framing — in case you’re not familiar with the term — refers to dividing a space into rooms with the use of lumber. It’s basically the skeleton of the home. Framing must be done before insulation, electrical wiring, plumbing, and HVAC systems can be installed.

Because I built a pole building and not a regular frame construction home, the framer had to frame the entire inside of my designated living space area. In effect, he had to build my home within that space.

Here’s the upstairs right after the stairs were put in. The subfloor isn’t even finished yet in this July 7 shot.

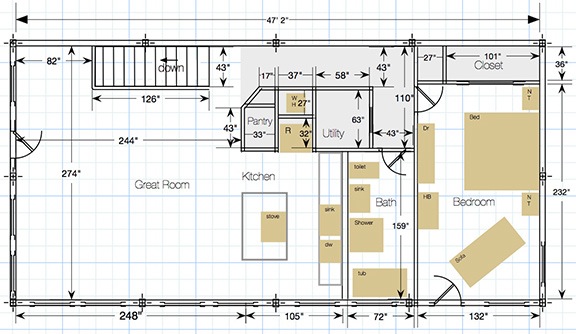

My living space is only 1200 square feet. In that space, I needed walls to split it into a bedroom, closets, bathroom, laundry room, pantry, and great room (with kitchen).

I got three bids. Although I wanted very much to go with a framer who came highly recommended by my next door neighbor, I found his partner’s attitude condescending and simply didn’t want to deal with her. So I went with another framer that a friend of mine had used for his home in Wenatchee Heights, a guy named Mark.

The Broken Planter

Things got off to a bad start.

Yes, I know it’s just a crappy little rock garden, but it had been there for months, unscathed by other truck drivers.

Mark keeps all of his supplies in a trailer — the kind that’s pulled by a semi truck. When he pulled in with the trailer, he ran over the corner of the little rock garden I’d built for my house number sign. It wouldn’t have been so bad if he’d admitted that he’d done it and apologized, but his assistant played it all down, assuring me that they’d “fixed” it. It wasn’t fixed. It looked like crap.

I didn’t let it go. I voiced my concern about carelessness — literally dozens of truckloads of materials had been delivered down the same driveway past the little rock garden by large trucks over the previous three months and he was the first to hit it. I wanted him to understand that I was paying attention and that I wasn’t interested in letting little things go. Yes, I might be a woman acting as a general contractor on a construction job, but I wasn’t the kind of woman who could be pushed around.

It took me an hour to fix the planter and replace the crushed plant.

Floor Plans

The next little problem reared its ugly head soon afterward. I’d come up with a simple design for a floor plan that took into consideration window placement and approximate room size. I handed this off to Mark. Although I was prepared to work with him to lay out the chalk marks for the rooms, he told me he’d do it with his assistant and I could review them that evening when they were gone. Assuming that he’d use my floor plan as a guideline, I let him get to work.

The version of the floor plan that I gave Mark was a lot like this. The posts in this drawing are round.

I don’t remember why I came up to check on the progress a while later, but I’m very glad I did. He was using my floor plan as a blueprint for the walls. Unfortunately, my floor plan did not include exact measurements and did not take into consideration the thickness of walls: 5-1/2 inches. So when they marked the wall between the bedroom and bathroom, it extended past the post I’d used in my design to divide the rooms. When I came up to take a look, he was measuring the wall between the bathroom and kitchen, placing it right in the middle of the kitchen window.

When I pointed this out, his response was, “Well, they shouldn’t have put the window there.”

“I told them to put the window there,” I said firmly. “This is my design.”

It wasn’t worth explaining the concept of symmetry to him. I thought he’d understand — I thought someone who built homes for a living would understand something about design aesthetics. Fortunately, I didn’t have to. My anger over the entrance planter incident was probably still fresh in his mind. And, like me, I’m sure he often recites the mantra, “The client is always right.”

Whatever.

I did explain that the measurements were rough estimates and that they didn’t take into consideration wall thicknesses. I explained that the walls needed to be set in relation to the windows. And then I spent the rest of the morning with him while he laid down the chalk marks. We had some difficulties with the pantry, which had crept into the living room — too many walls! — but we fixed that by making a much smaller pantry.

The Work Begins

They got to work the next day. Mark had a ton of experience and things went quickly. His assistant, however, seemed to need a lot of guidance and that was slowing things down. The speed of their work didn’t bother me — I was paying by the job, not by the hour — but I think it frustrated Mark.

Framing in progress.

To save the $500 cleanup fee, I’d elected to do job site cleanup myself. (Frankly, I think it was dumb of him to put cleanup as a separate line item. If they’d just clean up as they went along, there wouldn’t be much to do. If the amount had been included in the cost of the framing, I would have paid it.) Each day, I’d go upstairs, sweep, collect nails and small scraps of wood, and throw away Gatorade and water bottles. That made me the daily inspector of their work, too.

One thing he did that wasn’t in my plans was to relocate my bedroom door. I’d wanted it a bit farther down the hall, closer to the bathroom door. He’d put it right next to the closet wall. I thought about making him change it, but then realized that his design would probably make it a lot easier to move furniture into the room. I left it as is.

This terrible picture of George at work shows how fearless he is — he’s standing on a scaffold above my open stairway, at least 20 feet off the ground.

After a few days, the young assistant stopped coming and George, his more experienced assistant, showed up. I like George. He’s got a really upbeat personality and a good sense of humor. A real pleasure to deal with. And unlike Mark or his younger assistant, George didn’t seem afraid to climb the scaffolding to get to the high areas — at its highest point, my ceiling is 18 feet off the ground — even over the open stairwell.

Finishing Up

Mark had a deadline, which was determined by another job he needed to start right after mine. In the end, I think that’s what got them to finish up within two weeks.

Here’s how the framing looks today with the area (mostly) cleaned up. This shot was taken from the northeast corner of the living space, in what will be the great room, looking toward the kitchen.

I think the job was a lot more work than Mark had expected. It certainly looked like it should cost more than what he’d bid. But when he gave me the final bill, it wasn’t any more than he’d told me it would be. I thanked him and wrote him a check.

Later, I went upstairs and measured everything. I updated my floor plan drawing to reflect actual measurements and then even began drawing in furniture to scale to make sure it’ll fit. (Admittedly, the bedroom will be tight with my king-size bed, two night tables, two dressers, and sofa. The sofa may wind up in the consignment shop in town.) Eventually, I’ll get around to drawing in the rest of the furniture. There doesn’t seem to be much of a rush — there’s still so much to do. In the meantime, this drawing is useful for estimating building materials and planning my kitchen cabinet layouts.

Here’s the final floor plan with wall widths taken into consideration. The gray shaded area is a loft 8 feet off the floor over the hallway and utility areas.

I will admit that I wasn’t sorry to see that ugly trailer pull out of my driveway.