My false start on a flooring purchase.

I have been thinking about flooring for my new home for a long time. A very long time. This month was the month to finally make a decision — and a purchase.

What To Buy?

I know what I don’t want:

- Carpet. I hate it. ‘Nuff said.

- Tile. It’s a pain in the ass to lay and, since my subfloor is plywood, I’d have to lay hardy backer under it. So that’s an added step with an added expense. And I hate scrubbing grout.

- Vinyl. Any kind of vinyl: sheets, tiles, etc. Yes, I know vinyl has come a long way since the 1980s when it looked like cheap crap or the inside of a school, but I just can’t wrap my brain around living in a place with vinyl floors.

I know I wanted my floors to either be wood or look like wood and be durable enough to last 15 years or more without any problems at all. I also wanted it to feel like wood — you know, that textured feeling that wood sheets can have? That left hardwood, bamboo, laminates, and something engineered, like Pergo. These were all available with snap-together installation to create a “floating floor.” No nails or glue. Wood-like planks simply fit together over padding to create a floor. Lots of my friends had gone with one of these options and they all raved about what they’d chosen. Seemed to be a safe bet.

But which to choose?

I had a budget for the floor, which was determined not only by my available cash but the simple fact that I was building a living space over a garage and spending $6/square foot for flooring was an investment I’d never get a return on. That pretty much knocked hardwood and bamboo out of the picture.

Of course, that also means that if you have trouble making a decision, there’s no one with a vested interest to help you.

Fortunately, I’m usually good at making decisions.

I must have looked at flooring at 10 different places, including online. (I’m sorry, but can’t imagine selecting a floor online where you can’t touch and really see what you’re getting.) Prices were all over the map, from 99¢/square foot to well over $4/square foot. To make my decision-making process easier, I decided to set my spending limit at $3/square foot including tax and padding. Then I went to Lowe’s, where I could put the purchase on my zero-balance Lowe’s credit card at 0% interest for 12 months, parked myself in front of the flooring displays, and tried to decide what to buy.

Color was a definite issue. I didn’t want the floor to clash with my kitchen cabinets. Or my red sofa. Since the cabinets are light, I figured I’d go dark. The high-ceilinged rooms with their light paint and Navajo white ceilings are big enough to support a dark floor. It would make a good contrast.

At least that’s how my reasoning went.

In the end, I choose a Pergo Max laminate with the padding already attached. It was $2.49/square foot, which was under my budget, even after adding sales tax. Because the padding was attached, I didn’t have the cost or bother of dealing with sheets of padding. The install should go easy enough, especially if I had a friend who’d recently done an install stop by and give me pointers on the first day.

“Manor Hickory” is a very dark shade of brown with near-black highlights.

“Manor Hickory” is a very dark shade of brown with near-black highlights.

The color? Something called Handscraped Manor Hickory. I thought the dark highlights would look good with end tables I still needed to buy. The red sofa had looked good with black furniture and, in the back of my mind, I thought I might go with black again.

At least that’s how my reasoning went.

I did the math on how much I needed to buy: 70 boxes. I got a sales person to help me find the boxes in stock. Amazingly, they had enough for my needs. I instructed the sales folks to put 70 boxes on shrink-wrapped pallets for me. I’d pay up front, bringing one box with me for the cashier to scan, and then meet the loaders in the Lowe’s outdoor lumber yard with my truck.

I also bought a bathroom vanity and a countertop with a sink.

Bringing It Home

There are several reasons why I have a big truck. This is one of them.

Out in the lumber yard, they loaded my truck with the two pallets of Pergo and tucked the vanity into the space between them and the fuel transfer tank I have in back. We put the countertop with sink on top of the fuel tank. Then I took out some ratchet tie-down straps and secured them in place.

The Lowe’s guys figured that each pallet weighed about 1500 pounds. I’m not sure how true that is, but if it is true, I probably had about 2 tons of stuff in the back of my truck. As I drove away, I felt the weight. But the 1-ton Ford diesel handled it well.

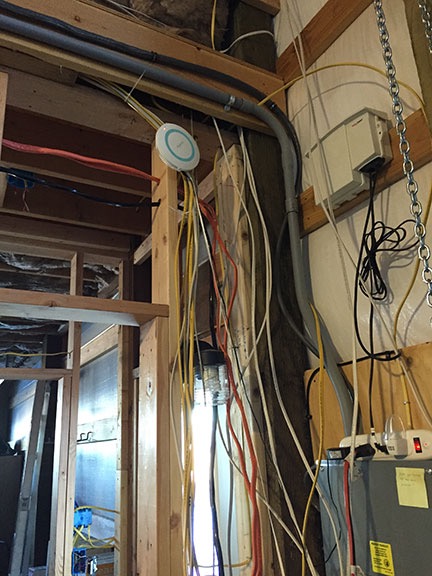

At home, the drywall guys were working in the bay where the truck lives. I’d already decided that I’d back it in for the night and worry about off-loading it the next day. I was having a party that night, a celebration with friends on the completion of the drywall and painting of my living space upstairs. I had lots of other stuff to do before I worried about offloading the flooring.

Later, after the drywall guys had left, when I had a minute of spare time, I went to open the garage door. Surprise, surprise! The drywall guys had made the ceiling too low in that bay — long story why — and I couldn’t get the door open more than two feet! Fortunately, there was no rain in the forecast. The truck would stay outside.

Offloading

The weather was beautiful on Saturday and I spent much of the day doing stuff outside in the yard.

I think I was secretly dreading unloading the truck. Because I didn’t have a forklift — I don’t have everything, despite what some of my friends think — I’d have to offload the truck one box of Pergo at a time. And I know from experience that no matter where I put it, I’d have to move it. (Ask me about the pavers one day, okay?) So I wanted to put it on something that could be easily moved. That meant a dolly.

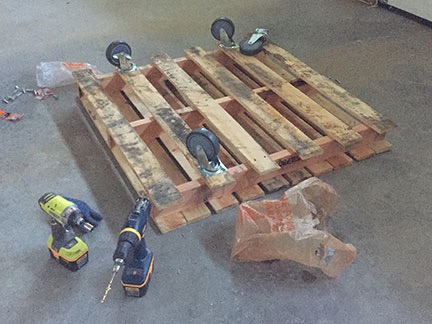

I already had a home-made dolly. My bathtub was sitting on it. I needed another one.

I had a very nice pallet outside that I’d asked the drywall delivery guys to leave behind. It was definitely large enough to hold one pallet of Pergo. I figured I’d make a dolly out of that and then make another dolly out of the pallet the first pallet of Pergo was sitting on. I’d leave one dolly of Pergo down in the garage and put the other one upstairs so it would be ready for installation.

All I needed were heavy duty caster wheels.

I took my Jeep to Home Depot. Two hours later, I drove away with it full of stuff, including 8 350-pound capacity wheels and the hardware I needed to fasten them to the bottom of pallets. Those were the most heavy-duty wheels I could find. They’d have to do.

Building a dolly is as easy as attaching good wheels to the bottom of a heavy-duty pallet.

My finished pallet dolly.

I stacked the boxes of Pergo on the dolly.

On Sunday morning, I put on some music, gathered some tools and got to work. It didn’t take long to turn that pallet into a very heavy duty dolly. The wheels were great and rolled smoothly on the clean floor, which I’d hosed out the day before.

I cut open the shrink wrap on one pallet of Pergo and started offloading the boxes, one at a time, and placing them on the pallet dolly. I don’t know what they weighed — maybe 30 pounds each? Not too heavy to lift, but not light, either. The length was perfect for me to grab them from the ends. I could feel the muscles in my arms getting a good workout.

Every time I finished a layer of Pergo, I’d move the dolly around a bit to see how well it rolled. After four layers, it was definitely feeling sluggish from the weight. But I suspected it would hold the entire pallet load. Time would tell.

An Unfortunate Realization

I was almost finished offloading that first pallet — I think I’d done the first four stacks — when I realized that one of the boxes was wet on top. The truck was parked in such a way that condensation from my roof had dripped down on it. I grabbed the box and got a rag to dry it off. The water was under the plastic wrap. I needed to open it to dry it properly.

And then I got a brainstorm. Why not take this box upstairs and lay it out to get a good idea of what it might look like on the floor?

A smarter person would have done this first, before offloading 28 30-pound boxes of flooring. Just saying.

I began laying out floor planks to check the color. What was I thinking? Of course it was too dark!

I brought it upstairs, dried the top piece, and set it down on the floor. It looked horrible. Way too dark.

I was in denial. It couldn’t be that bad.

Ten minutes later, the entire box was laid out in the corner of my living room. I didn’t like it. I realized that it was almost the same color as my dining table and chairs and just a tiny bit darker than my bedroom set. My furniture would blend into the floor.

I stayed in denial. Surely it couldn’t be that bad. I needed a second opinion. I called my neighbor, Kathy, who lives at the winery a half mile down the road. She was also a house painter who did a lot of decorative work. She’d have a good idea of whether it was okay. She was out pruning grape vines with her husband but promised to come in about 20 minutes, when she needed a break anyway.

She came and climbed the stairs with me. The first thing she said was, “You’re going to see all kinds of dust on that.” I’d already had that warning from other people when I mentioned wanting a dark floor and I knew she was right — it had gotten dusty just from being laid out. But I had a Roomba vacuum robot and wasn’t very concerned about that. It was the color that bothered me.

Although she didn’t seem to think it was bad, by that time I’d already decided that it was too dark. She agreed with me that if I didn’t like it now and didn’t change it, I’d regret it. I thanked her for coming and watched her drive away.

Shit. Back to square one.

Return and a New Choice

I loaded all the boxes of Pergo back onto the pallet in my truck and, since I couldn’t shrink wrap them, used the ratchet tie-downs to keep them together on the pallet. I wiped down each plank in the open box, stacked them neatly in the box, and put the box in the front of my truck. Then I loaded up Penny and drove back to Lowe’s.

Of course, I was a mile down the road when I realized I’d forgotten my cabinet sample. I made a u-turn, came home, got it, and left again. (I forget something I need about 25% of the time that I leave home and usually remember it before I hit pavement.)

One thing you have to love about Lowe’s and Home Depot is how easy they make it to return things. I brought the open box and my receipt to the counter and let them offload the truck and count the boxes while I went back to the flooring display to make a new decision.

I ended up with Tidewater Oak.

Fortunately, a knowledgeable salesperson appeared. With her help, we narrowed it down to three options. One did not include the attached padding, so I knocked it off the list. The other was a tiny bit too light. The third one seemed just right: Tidewater Oak. Although it didn’t have that “handscraped” texture I liked, it did have some woodlike texture. And it looked just like the hardwood floor I always wished I had.

Fortunately, they didn’t have any in stock. I say “fortunately,” because I also had to pick up a special order at Home Depot and I would never fit it in the truck with the Pergo. I placed my order and was told it would arrive within a week. Then I went back to the return counter, signed a form to get a refund, and went to the cashier to pay for my special order. Done.

At nearby Home Depot, I picked up the acrylic block walls for my shower stall, a shower pan, and a new miter saw. But that’s another story.

More To Come

So that’s the story of how I almost got my flooring. Obviously, there’s more to come when the new floor arrives and I start laying it. Stay tuned.