Hard work, but not a difficult task.

This past week, I made a radical decision: I decided to install my own temporary power box at my future homesite.

Temporary power is what’s commonly installed at a construction site to provide power to the builders for their tools. It consists of a 4×4 post with a circuit box, meter, and outlets. Chelan County is very specific about how the box should be installed. It’s all detailed in their 74-page book, Residential Electrical Services Connection and General Information,” which is available as a PDF from the Chelan County PUD website.

Temporary power is what’s commonly installed at a construction site to provide power to the builders for their tools. It consists of a 4×4 post with a circuit box, meter, and outlets. Chelan County is very specific about how the box should be installed. It’s all detailed in their 74-page book, Residential Electrical Services Connection and General Information,” which is available as a PDF from the Chelan County PUD website.

I’d spoken to two electricians about doing the work. One wanted $500, which included “renting” me the post for six months. He never did say what it would cost if I still needed it after that. The other promised to come look at the site but never showed. I called him to follow up and left a message. But by the time he called back, I’d already made my decision.

A friend of mine had a power post he no longer needed. All I needed to do was buy some more outlets and wire and some conduit and a grounding rod. He went with me to Home Depot and an electrical supply place. I spent $120 for the items I needed, along with a electrical how-to book.

The biggest challenge, he told me, would be to get the hole dug and drive in the copper grounding rod. The rod was about seven feet long. It had to be driven all the way into the ground. He said that driving in that damn rod would be the hardest part of all.

I went out to the property the next day. I wanted to scout out where I’d put the pole. I also wanted to measure the distance from the pole to where I planned to park my RV during construction. I was hoping to run 30 amp power to the RV. I needed 75 feet of cable. I think I had 50. I began rethinking the parking space.

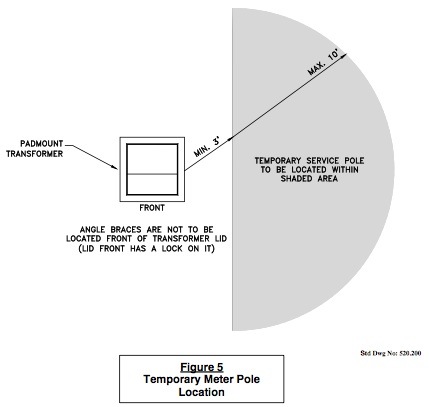

You see, the power pole has to be 3 to 10 feet from the transformer, which is already on the property. So I’m limited as to where I can put the pole. Fortunately, the transformer and pole location will be quite close to the building site. That’s good because the building must be within 100 feet of the transformer. So I’m all set for that.

You see, the power pole has to be 3 to 10 feet from the transformer, which is already on the property. So I’m limited as to where I can put the pole. Fortunately, the transformer and pole location will be quite close to the building site. That’s good because the building must be within 100 feet of the transformer. So I’m all set for that.

While I was there, I took a shovel and thrust it into the dirt, expecting to hit rocks. After all, I’d had a hell of a time driving the T-post for my name/address sign three weeks before. But the shovel went in smoothly. I dumped a shovelful of dirt to the side. Easy. The next one wouldn’t be that easy, though.

I dug again. It was.

I got out my tape measure and measured about 7 feet from the transformer, in a line almost abeam my city water spigot. And I dug.

I dug for a good 15 minutes, always expecting to hit rock. I didn’t encounter a single stone.

I got pretty far the first day, just looking for rocks I never found.

By that time, I had a good trench going but I was sweating hard. It was afternoon on a sunny day. I wasn’t dressed for digging. My foot, which I’d sprained more than two weeks before, ached. I’d have to come back earlier in the day, before it got warm out.

That day was yesterday. I showed up at 8 AM. After a little weed whacking to clear the area, I got to it.

The trench needed to be 24 inches deep. The hole for the pole needed to be 36 inches deep. Unless you’ve actually dug a trench and hole that deep you have no idea how deep it really is. It’s deep.

But there were no rocks. The dirt came up easily, shovel after shovel. I had no trouble getting down to 20 inches on the trench and 30 on the hole. Then it started to get a little harder — the dirt was packed solid.

I drove down the street to where my friend Kathy lives. She’s an avid gardener. She was outside with her husband, talking about plans to add a new tasting room to their winery. I asked her if she had a “digging stick.” I described it as a long, pointed pole that was heavy. I had one back in Wickenburg but had left it behind. No problem. Kathy had one. And a post hole digger. We loaded both into my truck and I drove back.

I pounded with the digging stick to loosen up the soil. The post hole digger worked great to pull the dirt out of the trench and hole — after all, they weren’t much wider than my shovel — but was too heavy for me to work over and over. I went back to the shovel.

By 11 AM, after several breaks, I was done.

But there was one more thing: the copper rod.

I brought it over to the hole and lowered down onto one side. Then I got the post driver I’d bought to put in my name/address sign and put it over the rod. I rammed it down hard. The hit made a gawdawful clanging sound, but the rod must have gone in 6 inches.

I put on a pair of earplugs and got back to it. Soon I was kneeling beside the hole, banging away with the fence post driver. When the rod was about 4 inches out of the ground, I stopped. I could always finish it off later.

Here’s the finished trench and hole, approved by my tiny inspector.

Here’s the finished trench and hole, approved by my tiny inspector.

I stopped and took a photo. When I put it on Facebook, my friends joked about using it to bury my wasband. We pretty much agreed that the ditch was so narrow he’d have to go in sideways. I told them I’d rather use it for its intended purpose since it was unlikely that I’d be able to cram his mommy in there with him.

On the way home, I stopped to chat with my next door neighbors whose home, the subject of my wasband’s investigation back in April, is nearly done. (I still giggle about that every time I drive by and see their RV parked there.) They were cleaning up after the builders — their way of saving some money. They’d loaded up their little flatbed trailer (another giggle) with scrap wood while their three sons played in the dirt. We exchanged phone numbers and talked about road maintenance.

Then I continued home, stopping just long enough to drop off the digging tools I’d borrowed.

Digging had been hard work, but it was surprisingly easy. As someone on Facebook mentioned, the lack of rocks was like some kind of good omen — it was meant to be. Still, you can bet I took plenty of ibuprofen last night.

As

As

I was able to pull the smaller plants out by the root. The slightly larger ones could be cut back with my weed whacker. But the larger ones were a real pain. The best way to get rid of them was with a

I was able to pull the smaller plants out by the root. The slightly larger ones could be cut back with my weed whacker. But the larger ones were a real pain. The best way to get rid of them was with a