Two visits, amazing results.

When I designed my new kitchen, countertops were a big question for me. Back in Arizona, I had tile countertops which looked fine and could handle direct contact with hot pots and pans, but lacked a smooth surface for rolling out pie/cookie dough and were a royal pain in the ass to keep clean. (Think white grout.) I knew I wanted an easier to care for surface, but I wasn’t sure what I wanted. The Home Depot kitchen design person helped me make the decision: granite.

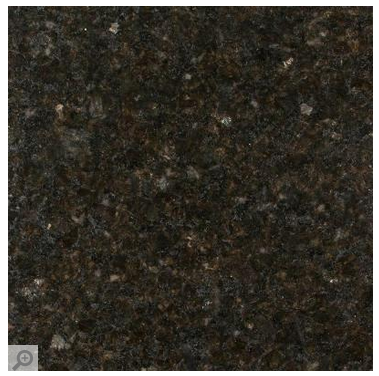

The color I chose is called Ubatuba, which is mostly black with greenish gold specks that work well with my cabinet and wall colors.

Granite! I’d always wanted stone countertops but it was just many of the things that were apparently not within the realm of possibility in my old life. Home Depot had a sale going on granite and I really liked one of their “level A” (i.e., least expensive) colors. Why the hell shouldn’t I treat myself to some nice countertops?

She worked up an estimate for the two countertops — main and island — and backsplash on the main island. She included the radius cut I’d need for the end shelf unit. I chose the simplest bevel, which was available at no extra charge. After an initial sticker shock with the final number she came up with, I signed and paid for my purchase.

That was back in January 2015.

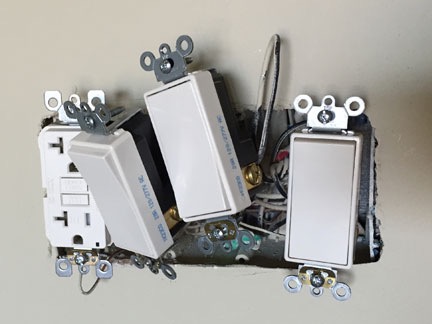

Some people might question why I went with Home Depot for my countertops. Simple: I used them for my cabinets and the price was acceptable. Installation was included. I didn’t have to visit a half dozen shops and be told a dozen different things about two dozen different options. I had enough on my plate as general contractor and electrician for the project. I wanted to keep things simple. That was worth maybe spending a little bit more than tracking down two matching pieces of granite, getting them properly cut and delivered to my home, and finding someone with plenty of experience to install them. Home Depot would take care of everything with their vendor so I wouldn’t have to worry about it.

The Template

My project started really coming together in February when the insulation, drywall, and painting was done. (I really need to blog about that one of these days.) I was on a 16-day vacation in Arizona when they were finishing up, but I scheduled the cabinet delivery for soon after my return. I had a shorter trip to California the following week and scheduled the cabinet installation for the day after my return from that trip. When I had a solid date for the cabinet installation, I booked the countertop measurement appointment. They needed the cabinets in place to create their template.

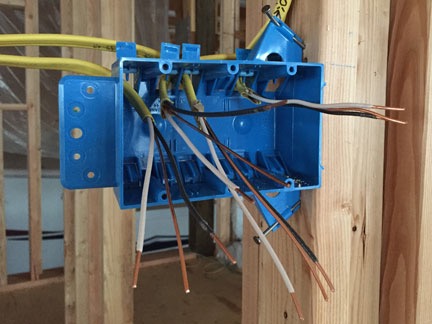

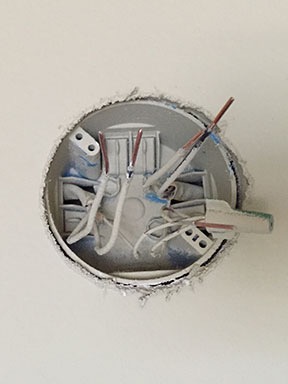

Two installers showed up on Friday, March 13 in a small truck with a bunch of previously used white corrugated plastic, tape, and a glue gun. While I continued working on my electrical system, they busied themselves in my kitchen, measuring spaces and cutting/gluing the plastic into the shape of my future countertops. That would be the template they’d use back in the shop to cut my countertops.

The templates for my kitchen countertops were made of corrugated plastic.

They asked me a few questions and tried halfheartedly to upsell me a fancier bevel, which I didn’t want. Then they advised me to get wooden corbels to support the breakfast bar side of my island countertop, which would overhang 12 inches. They told me the corbels should be 10 x 16 inches in size and that I should mount them with the long side against the wall. They advised me to avoid metal brackets because metal bends and wood doesn’t. I took notes, signed the paperwork they presented, and watched them leave.

Because the countertop company only came to the Wenatchee area once every two weeks from the Seattle area where they’re based, it would be two weeks before my countertops arrived. That was a good thing, mostly because the cabinet company had screwed up and made my lower end cabinet out of the wrong wood. It would need to be replaced. The cabinet folks and Home Depot were already on it. It would arrive in plenty of time before the countertop installation.

The Corbels

Getting wooden corbels the exact size the countertop guys recommended was not easy — at least at first. I worked the web over the weekend and found all kinds of corbels, none of which came very close to the size they suggested.

Then I found ProWoodMarket. This company makes and sells a huge range of wooden brackets, braces, corbels, and other decorative and structural wood pieces. I put in a request for custom corbels and got a response back within an hour. The price was within reason — actually, no more expensive than the non-custom corbels they offered on their site. Unfortunately, to get them on time, I’d have to either put a rush on the order or the shipping or both. I paid a rush fee to get my order to the front of the production line and took my chances on shipping. My order was shipped out the next day via UPS.

I took another trip to California. The package arrived the day I left — I saw it sitting on my doorstep in the view from one of my security cameras. Fortunately, the weather was good that week and I didn’t have to worry about the box getting soaked.

When I got home, I opened the box and was pleasantly surprised by the size and appearance of the corbels. They’d been carved out of cedar and I could see the character of the wood, including tree rings and knots. The color was perfect — I wouldn’t have to stain them. Just a clear coat finish — a woodworking friend suggested tung oil — and they’d last forever.

The trick was to get them installed on the stub wall of my kitchen island. The problem wasn’t finding solid studs to fasten them to — I could see exactly where the studs were because the top of the wall was unfinished and the fasteners I’d used to attach the studs were visible. The problem was lining them up to be level with the countertops — which where slightly taller than the stub wall — and holding them steady while fastening them into place. That took more than two hands. I’d need help.

My friend Bob came to the rescue. He’s off on Fridays and I asked him to come by after breakfast. I made a 6 AM run to Home Depot to buy the right fasteners — 4-1/2 inch super-duty wood screws — and wood buttons to cover the screw holes. He showed up around 8:30 AM and let me make him a cup of coffee while his dog, Skip, played with Penny. Then we got to work.

I have a lot of tools — and seem to be acquiring more every day — but Bob has even more. He brought along his Forstner drill bit set. These bits are perfect for making inset drill holes that would accept a wood button. We marked two places on each corbel to drill holes and Bob did his magic. Then we used my four-foot level to position each corbel against a stub wall stud, level with the cabinet tops. The screws sucked the corbels hard into place. We were done in half an hour.

The corbels after installation on the stub wall. I bought the wrong size wood buttons; need larger ones I’ll get on my next Home Depot run. (And yes, that’s a quiche on the stovetop — the first I baked in my new oven.)

The Installation

Although the installers were supposed to arrive between 8 AM and 11 AM on Friday, March 27, they were late. They called around 10 AM and claimed they were having trouble with their truck. That was disappointing; I’d been trying to get the plumber in that afternoon to plumb my kitchen sink and dishwasher and I knew he didn’t want to come on a Friday afternoon. The countertop delay gave him the excuse he needed to put it off until Monday. It was a good thing, because the countertop guys didn’t actually arrive until after noon.

Here are the installers, carrying up the countertop for my kitchen island. I can only imagine what this piece of stone weighed.

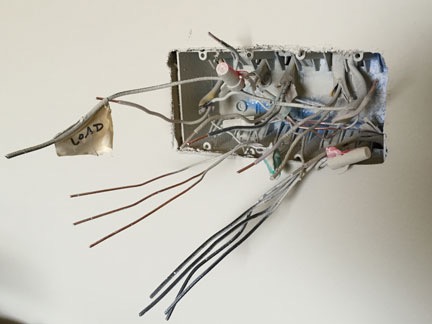

They didn’t waste any time — I might have been their first installation for the day, but I wasn’t their last. One by one, they brought the two pieces of my main countertop in through the front door and up the stairs. (The countertop was more than 12 feet long and couldn’t be created in one piece; there would be a seam in the middle of the sink.) When they laid one piece atop the cabinets near where my sink would go, I saw how perfect the color would go with my cabinets and walls.

While they worked, I stayed out of their way. I had begun laying Pergo in the great room while I waited for them and kept at it, stopping every once in a while to check out their progress and answer questions. They had a lot of small tasks to do, including setting my under-mount kitchen sink in place and drilling the holes for the faucet and soap dispenser. They worked slowly and carefully — a team that obviously knew exactly what they were doing and wasn’t going to let their late start affect the quality of their work.

The countertop installers align the two halves of my main kitchen counter.

It took them nearly three hours to do the job. That included laying in the back splashes, setting the stove in place, applying a sealant to the granite, and caulking everything that needed caulking. When they were finished, it looked — well, amazing.

I can’t believe how good my kitchen looks now that the countertops have been installed.

They packed up, had me sign a few papers, suggested that I apply granite sealer again, and gave me some advice about not putting hot pots on the stone. I gave them some cash and told them to have dinner on me. Then I watched them drive away.

Another milestone: brewing coffee on the countertop in my new kitchen.

Later, I brought my coffee maker upstairs and set it on the counter. This morning, I brewed my coffee in my new kitchen for the first time.

Tonight is “ladies night” again at my house. It’s a special occasion: Kitchen Box Unpacking. We’ll enjoy some wine and munchies while I unpack the multitude of boxes packed with kitchen things I brought from my old Arizona home. I’ll see what fits in my drawers and cabinets — whatever doesn’t fit or I don’t want anymore, I’ll give out as door prizes to my guests. Should be fun!

When I couldn’t find a cheap replacement for the battery charger, I simply bought the same drill, which came with a new charger.

When I couldn’t find a cheap replacement for the battery charger, I simply bought the same drill, which came with a new charger.