Do people really fall for this crap?

I used to own a Kitchenaid blender. It was a pretty simple model with a glass jar. I didn’t use it often, but it worked well enough when I did. Until it broke.

I’d bought one of those Magic Bullet blenders to use in my RV when I traveled. Because I didn’t replace the Kitchenaid, I started using it at home, too.

A Magic Bullet blender

A Magic Bullet is basically a blender base with two different blade assemblies and a bunch of plastic cups that the blade assemblies screw into. You fill a cup with what you want to blend, screw on the blade assembly, turn the whole thing upside down, and stick the bottom of the blade assembly into the blender base. When you push down and twist, the blender turns on.

Nowadays the “original” Magic Bullet comes with only a few cups and lids. But when I bought it, it came with about a dozen. I’m not sure why. They were a pain in the ass to store so I threw most of them away, keeping just one of each size. Ditto for the rings that turn the screw-top cups into smooth-top cups. (I’m not going to drink out of a plastic blender cup.) And the lids.

Let me be clear: the Magic Bullet is junk. It’s the same kind of disposable appliance so many Americans bring into their lives. Cheap and functional, but not exactly reliable. I knew mine would break and I knew I would throw it away. The only thing that surprised me is how long it lasted before it finally broke: maybe 8 years?

But it did break. And I was left blenderless.

My Braun immersion blender is part of a set that includes a chopper and whisk. I often use the whisk to make fresh whipped cream. I don’t think I’ve ever used the chopper. Maybe I should?

Well, that isn’t exactly true. I have one of those immersion blenders. It’s like a stick that you put blade side down into a pot of soup to puree it while it’s cooking. Mine’s a Braun and it works very well. I didn’t use it often until my Magic Bullet broke. Then I started using it to make smoothies. It got the job done — I’d just stick it into a big cup full of the ingredients and whir it until it was smooth — but I had to be careful if I didn’t want smoothie all over my kitchen.

Clearly, it was time for a replacement blender.

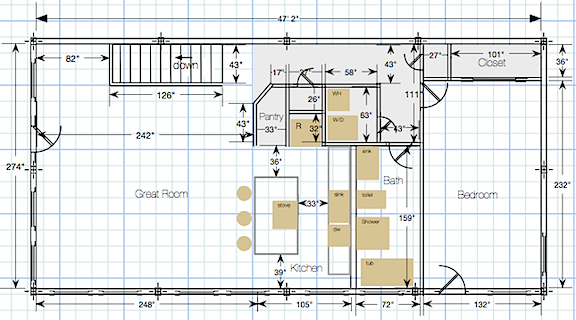

I mentioned it to my Facebook friends and the recommendations started coming in. Apparently, there are a lot of folks out there willing to pay in excess of $300 or $400 for a blender. I think they must use it a lot more than I do. I just wanted a small and functional kitchen appliance that I could store on a shelf in my pantry when not in use.

I was in Costco last month and saw that they had a Nutri Ninja, which another smoothie-making friend had mentioned. Yesterday, I went in to look for it. It was there, next to the $350+ Vitamix, selling for just $99. But it had a lot of parts — those damn blender cups — and I seemed to recall another model with fewer cups and a lower price. I found it hiding behind the Vitamix display for $69. Less parts, less money. I put it in my cart with the other things I’d come to Costco for.

Not the blender I thought I was buying, but I honestly don’t care.

It wasn’t until I got home that I discovered I’d bought another Magic Bullet.

What fooled me was the larger size and the prefix “Nutri” in the product name. It was a NutriBullet, not a Nutri Ninja. Sheesh. I really should pay attention when I shop.

Another person might have taken the damn thing back to Costco. But I honestly didn’t care. All I wanted was another cheap blender and that’s what I got. This one was bigger and beefier with bigger plastic cups than the old one. If I got 5 years out of it, I’d be happy.

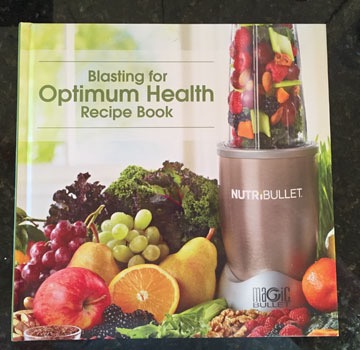

On the surface, this looks like a recipe book, right?

What surprised me, though, was the hard-covered book that came with it. On the surface, it looked like a cookbook. Later, when I went to bed, I took it with me to browse it before I went to sleep. It took only moments to realize what it really was: a piece of marketing material designed to fool people into thinking that they’d bought some kind of special nutrition machine that would make them healthier and help them lose weight like no regular blender could. After all, they’d bought a “nutrition extractor,” not a blender!

“Nutrition extractor”? It’s a freaking blender.

Yes, the book had recipes, but it also had a lot of nutritional information about trendy “superfoods” like cacao nibs, organic chia seeds, organic goji berries, and organic maca powder. There were pages and pages about these “foods,” along with information on how you could order them from the NutriBullet website.

And the testimonials! Pages and pages of them from people praising the NutriBullet to high heaven. Here’s an example closing line for one that stretched two full pages:

It has touched my life in more ways than I can explain.

Seriously? A blender? You really need to get out more, Daniel.

I especially liked the recipes that required you to cook a bunch of ingredients, wait for the mix to cool, and then “extract” it in batches before reheating it again. News flash: an immersion blender like my Braun can do it without cooling the soup down, saving hours of food prep time.

In all honesty, I found the recipe book offensive. Cover to cover, it was full of marketing bullshit, touting the mostly imaginary benefits of a crappy blender. I couldn’t believe anything I read inside it and felt insulted that someone thought I might. And the stock photos of the attractive 60+ men and women enjoying their healthy lifestyle were a real turn off. Is this blender for old people?

It amazes me how low marketers will stoop to sell an inferior product.

Anyway, I’ve already tossed the book into my Goodwill box. Maybe someone more gullible than me will find it worth reading.

And yes, today I’ll give it a try. But I won’t be making a “nutriblast.” I’ll be making a good, old fashioned smoothie, just like I always have. And you can keep the goji berries.