Two days of heating and hammering metal.

• Red Top Lookout

• American River Campsite

• Mt Rainier and the Buck Creek Campsite

• A Driving Day with a Crappy Campsite

• The Blacksmithing Weekend

• Dungeness Recreation Area

I have been interested in blacksmithing — heating and hammering metal to shape it — for a while now. In a sense, it’s related to the metalsmithing work I do with my silver and copper jewelry, but rather than cold working relatively small pieces of soft (annealed) metals, blacksmithing involves hot working larger, harder metal: steel. So last month, when the Tacoma Metal Arts Center announced the Blacksmithing Weekend course in the Seattle area, I immediately signed up for it and then began planning my vacation around it.

And that’s why I was in Eatonville on Saturday morning after a terrible night’s sleep, following Google’s directions to a five-acre farm with a huge shop on the outskirts of town.

The Setup

Mike has a YouTube channel to provide information about the equipment he makes. He’s also interested in doing tutorials. If you’re reading this because you searched for “blacksmithing,” be sure to check out his YouTube channel, Mathewson Metals, and give him feedback about what you’d like to see. Oh, and please do subscribe; that’ll help motivate him to make more content.

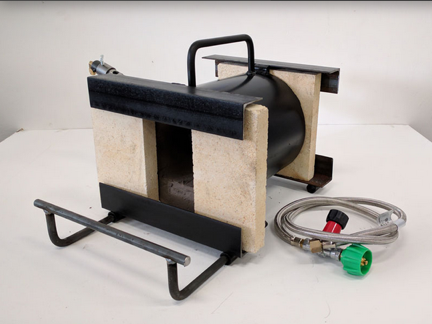

The class was taught by Mike Mathewson of Mathewson Metals. Mike has been blacksmithing for years and has done all kinds of work, from the small projects we created over the next two days and tools to much larger furniture and architectural installations. He’s also the inventor and manufacturer of several different simple, affordable, propane-powered forges, one of which was in use for the whole weekend.

This is the MetalSmith Propane Forge that we used in class. You can see a video of it in action here.

The class was conducted on one side of his 48 x 72 foot shop building, with the big sliding door on that end wide open to let in lots of air. (The air wasn’t anything we could call fresh, though, since the wildfire smoke situation only worsened over the weekend.) He had the one forge set up as well as several anvils and vices, with dozens of hammers in all shapes and sizes to choose from. He used an amazingly quiet Jet metal saw to cut the 3/8 inch mild steel rods we used for our projects and I watched it in awe nearly every time he ran it. He had lots of other equipment that we didn’t use, like an old Little Giant power hammer and various cutting and finishing tools. The place was a bit of a mess outside our work area; he had only been in the space a little more than a year and he was still figuring out the final organization he wanted. He spent a lot of time organizing while we worked on our own, staying nearby in case we had questions or needed help.

Because of COVID-19, class size was limited to four students. We started with three: me, Travis, and Gary. Gary made a phone call while I went back to my rig to get a flannel shirt. When I returned he was apologizing and saying goodbye; his wife was ill and he needed to get back home. So that left two of us for the class, which was fine with me.

Travis already had a forge and anvil and a bunch of other equipment at home. He was serious about learning blacksmithing and wasn’t moving forward with his self-taught skills. I hoped he’d get an “aha moment” that helped him break through whatever was blocking him in his own shop.

Of course, I wasn’t very serious at all — I just wanted to try it out — so if there were any situations where we had to work one at a time, I usually let Travis go first. As the weekend wore on, we developed a good working rhythm when we had to share a tool; while I heated my piece, he’d work on his and then we’d switch positions. Very efficient. I’m not sure if it would have gone that smoothly with three of us.

The Projects

Mike has obviously taught this many times before. He’s a good, patient teacher who explains everything clearly before we start work. He uses visual aids when necessary to illustrate processes. He is encouraging and never tells you when you get something wrong — unless neither of us did? Instead, he points out a way you can do it better or easier to guide you on the right path.

Here’s the nail hook project. From left to right: bar we started with (this is actually Gary’s, which he never did more than mark with dots to identify as his), my version, Travis’s version, and the model we were going for. I made my nail part too long so I made my twist a lot shorter — too short? — and ended up with a sort of wimpy hook.

We did four projects, all of which were made from varying lengths of round or square 3/8 inch mild steel rod: a nail hook, a pair of blacksmithing tongs, a fork, and a spoon. Each project taught and gave us an opportunity to try or practice specific skills. For example, the nail hook got us to hammer one end into a point, hammer the other end into a paddle, twist the rod, and then bend the rod in a variety of ways. The blacksmithing tongs had us create two rectangular paddles, bend the paddles to be able to grip 3/8 inch steel rods, bend the rods into a scissors shape, and then rivet a pivot point between them. You’d start a project thinking “how the hell am I going to be able to make that?” and Mike would break it down, step-by-step until you were done.

I have to admit that I was surprised that I was able to “keep up” with the class — especially given that my classmate already had some experience and I had none. Well, that’s not actually true. A lot of my silver/copper forming techniques did apply to the steel work. I think that’s what allowed me to give most of my shapes a decent form and not embarrass myself.

My four projects. They need to be wire-brushed to take the fire scale off.

The class ran two full days — 10 AM to 6 PM — with just 30 to 45 minutes for lunch. In that time we finished three of the projects and had gotten a good start on the last one, the spoon, which only required that we finish it to match the fork. Travis will probably finish his up this coming weekend; mine will likely remain as is forever.

Fringe Benefits

A look over the fence at the pigs, which were actually quite large and didn’t stink.

A fringe benefit for me at the class is that Mike kindly let me park in his yard overnight, so I didn’t have to scramble (again) for a place to stay. He had me back into a space near his pig yard, then moved the two pigs out so I wouldn’t be bothered by their grunting. The space behind my rig was perfect for my pups to go out and take a pee first or last thing in the day.

There were a ton of huge, fresh blackberries along the road in front of Mike’s house.

We also went for walks out on the road in front of his home. The first walk is when I spotted the blackberries, which were mostly ripe and ready for picking. I ate a few right off the bushes. Later, I asked for permission to pick them and filled an empty clamshell container (previously holding a pound of fresh dates) with the nicest blackberries I’d ever seen. I’ve been eating them with breakfast since then.

On to the Next Destination

When class was over, it was time for me to bug out. I had planned to stay at Dungeness Recreation Area near Port Angeles that night. It was over two hours away by car. I detest driving in unfamiliar areas at night, so the last half hour or so was brutal for me. We made it by just after 8 PM and I was very happy to back into a campsite in the forest.

Discover more from An Eclectic Mind

Subscribe to get the latest posts sent to your email.

Blacksmithing is obviously one of those terms which has been changed across the US /UK linguistic divide!

To me that term means fitting a hot metal shoe, specially shaped, to protect the hoof of a working horse. That is an incredibly difficult task which involves knowledge of horses, their control, their confidence, and their great weight, on your back! There are few amateurs and a two day course would be impossible.

The course you went on was decorative ironwork. Something very different…

You did well in the iron work class.

I actually used a hot shoe farrier (the term here for a horseshoer) back when I had horses. Amazing to watch.

Here blacksmithing is anything you do by heating metal (usually steel) and forming it, normally with a lot of hammers and an anvil.

Thanks!