It’s mostly in my hands.

I don’t know about other parts of the country or world, but in Washington State, where I live, an owner/builder can get a permit to do all of her electrical work. In an effort to save money, take a hands-on approach to the construction of my new home, and keep myself out of trouble during slow winter months, I chose this option and became my own electrician. I’ve been blogging about this for the past few months; I have links to specific posts in this one.

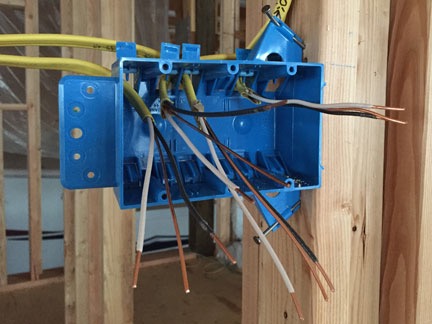

Like the plumbing work, which I blogged about over the weekend, electrical work has multiple parts. Back in September, I brought the power into the building. I guess that would be considered ground work. The rough-in stage would be getting the wires into the device boxes throughout my home and bringing the home runs down to the circuit panel; I did that in December and January. The final stage, finish, consists of attaching the ends of the home runs to circuits in the circuit panel and then putting devices on every device box in the home.

When I say devices, I’m referring to the electrical components you interact with: outlet receptacles to plug things into, light switches to control lights and outlets, and fixtures such as lights and smoke detectors. Every device on a circuit needs to be wired property before you turn on the circuit. The more devices you have, the longer it takes.

I know I joked about the vast number of outlets I have in my home, saying “You can never have too many outlets.” Well, when I started wiring them myself, I realized that you can.

Prepping for the Job

My home consists of mostly 15 and 20 amp circuits. Although I wanted to use 20 amp throughout, I soon realized that working with the thicker 12 gauge (as opposed to 14 gauge) wire would destroy my girly fingers. The main drawback to having a mix of circuit types is the fact that the device rating must match the amperage. So I couldn’t use a 15 amp rated receptacle or switch on a 20 amp circuit. That meant buying a bunch of each type and carefully matching them as I worked my way from room to room, wiring devices.

Here’s my wiring cart as it looked during the rough-in stage.

I set up a rolling cart to make the chore easier. The cart came from a school surplus sale I attended last year. It’s an old media cart with three shelves. On top, I laid out my electrical tools: pliers, wire cutters, wire strippers, screwdrivers, electric screwdrivers, bits, utility knife, hammer, drywall cutter (obtained near the end of the process), etc. Below that, in bins, I laid out 15 amp and 20 amp receptacles and switches, as well as a wide variety of switch plates and wire nuts. At the very bottom of the cart, I had a box of wire pieces I could use to create pigtails, as well as a small box for wire trimmings I could recycle. A garbage pail attached to the cart made it easy to keep my worksite neat and clean. I even had hooks I could use to attach my stepladder. I’d wheel the cart from room to room as I worked, keeping my tools nearby. I also wore kneepads and had a gardening pad to further cushion my knees when I did work near the floor.

I bought just about everything at Home Depot; not only did I get a 5% discount on every purchase, but they have an outstanding return policy that encourages people to buy far more than what they think they need and simply return the excess. In the beginning, I just bought huge quantities of everything I thought I might need. I was at Home Depot nearly every day and really got to know the staff. (It’s gotten to the point where they ask me how my project is going when they see me and I show off photos to them.) As the work progressed, I’d return some items and pick up others. Just the other day, I was so close to finishing that I took an inventory of what I still needed, compared it to what I had on hand, and made a “final” return/purchase trip. I have some spares left in case something needs to be replaced, but I don’t have bins full of devices anymore.

Getting the Job Done

I went room by room, trying hard to do one full circuit at a time so I could power it up and test it. The first circuit I completed upstairs was for my living room lights. That was only six devices. I then did the circuit for outlets on the south side of my great room — another five devices, including one outside on the deck. After that, I wired devices as I needed to, completing both kitchen circuits, the range circuit, the dishwasher circuit, the laundry room circuit, and the dryer and water heater circuits.

Things slowed down after that. I had some traveling to do, including an unscheduled trip to California, and that broke my momentum. A friend helped me install my ceiling fans, which hang 13 feet above the floor. I waited for deck fixtures to arrive, realized they weren’t quite right, and had to return them. Then I waited for the replacements to arrive. I tried (and failed) to install the track lighting in the hallway by myself. (It really needs two people to hang.) I wired all the devices I could but still found myself waiting for missing devices or another pair of hands to finish off the circuits.

How It’s Done

The difficulty of the actual work varied depending on the device(s) that needed to be wired. The easiest were the single gang boxes for outlets and switches. One or two sets of wires come into the box and you attach their ends to a device, screw the device into the wall, and screw on a cover plate. Done. I averaged about 10 minutes per outlet throughout my home.

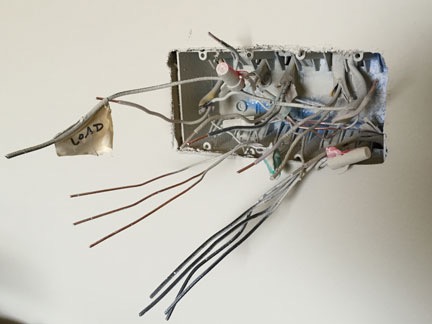

Originally, the bathroom switch box had only three devices; I had to swap in a bigger box to accommodate the switch for the exhaust fan.

With the drywall in place, it’s hard to see where the wires go.

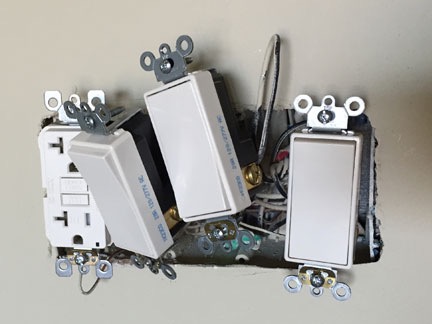

The switches are connected and ready to screw back into the box. This can be difficult with a lot of thick wires in the box.

The finished box. Well, finished until I open it back up for a little rewiring.

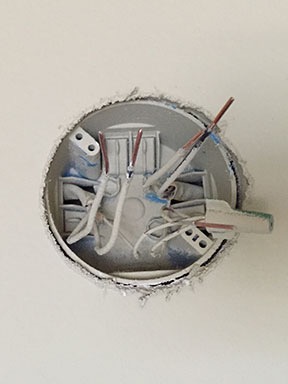

Other boxes were more complex. For example, the box shown here is for my bathroom. It has six sets of wires coming into it: source of power (home run), vanity light, exhaust fan, sconces, and two outlets. The box needed to be wired with one GFCI outlet that the other two outlets needed to be wired into for GFCI protection as well as three switches for the three other devices. Although it was pretty easy to see where the wires came from when there wasn’t any drywall (top image), it became a little tougher once the walls were on (second image). Fortunately, an electrician friend had advised me to mark wires as “load,” giving me a clue on how I needed to connect the wires. I wired the outlet and switches (third image), then screwed them into the box and put on a switch plate (bottom image).

Later, after I’d installed the light sconces and the circuit was done, I flipped the circuit breaker to test my work. I was disappointed to discover that it wasn’t quite right — I’d mismarked the “load” wires and had connected the sconces as a load and a switch to an outlet. The result: when the circuit was powered up, the sconces came on and could not be turned off; their switch powered the outlet on the west wall. Oops. I’ll be opening that box and rewiring the outlet and far right switch later today. So far, this is the only one I’ve messed up, so I think I’m doing okay.

Wiring light fixtures was a bit of a pain because it required not only doing the wiring, but installing a bracket that would hold the fixture in place. The bracket styles varied from one fixture type to another. The picture-based instructions were either incomplete or inaccurate almost every time, so there was a lot of guesswork and trial-and-error involved. Here’s an example using one of my bathroom sconces.

Installing a bathroom sconce. Start with a fixture box with wires (left). Connect the wires to the fixture support — in this case, a metal plate (right).

Fasten the plate to the wall (left) and then fasten the fixture cover — in this case, a glass shade — to the plate (right).

Although installation of the first six fixtures went remarkably well, I’ve since learned that not all fixtures come with the hardware you need to get the job done. The bathroom sconces, for example, came with duplicate parts but were missing vital screws — some idiot at the factory had packed the wrong parts. Fortunately, I had screws to do the job — 8-32 size. (I quickly learned what size screws are needed for different components of a device and began stocking up on extra parts.) This bit me again just yesterday when I tried to wire the motion-sensor lights outside each garage bay — they came with three pairs of screws that the designers apparently thought would do the job, but none of them were long enough. Another trip to the hardware store before I can finish.

Tools Make the Job Easier

When I couldn’t find a cheap replacement for the battery charger, I simply bought the same drill, which came with a new charger.

When I couldn’t find a cheap replacement for the battery charger, I simply bought the same drill, which came with a new charger.

Having two battery operated screwdrivers really helped. I had bought one of them years ago but its charger was zapped in a power surge back in 2013. I realized that it was only a few dollars more to buy a replacement drill with a new charger than just the charger. But why throw out the old drill? They take turns getting charged. I keep a different bit in each drill and reach for the one I need as I work.

My electrician friend, Tom, also gave me a handy tool for tightening winged wire nuts. It fits onto my screwdriver like a drill bit and really does the job well. It’s all about tools.

Like a dearly departed wise man used to say, “Any job is easy if you have the right tools.” I can vouch for that.

What’s Left and Ladder Woes

At this point, I’m nearly done. Here’s my list of devices still needing wiring:

- 3 garage entrance fixtures (need screws)

- 4 garage ceiling outlets (need to man up and climb the ladder)

- 1 outside entrance fixture (need to man up and climb the ladder)

- 1 inside entrance ceiling fixture (need to man up and climb the ladder)

- 1 deck outlet (no excuse; this should be done)

- 6 deck fixtures (need 2 fixtures and need to man up and climb the ladder)

- 1 smoke detector (need to man up and climb the ladder)

- 3 sets of track lighting (help is coming on Friday for the cost of a rib dinner)

As you can see, I have a bit of an issue with ladders.

The problem isn’t having ladders. I have ladders out the wazoo. First of all, the drywall guys apparently took my 5-foot aluminum ladder, which is extremely easy for me to move around and left me their 6-foot fiberglas ladder, which is a better ladder but much heavier. And, of course, I already have a 6-foot fiberglas ladder, so now I have two. I also have an 8-foot aluminum ladder I bought for preflighting my helicopter. A friend loaned me his 10-foot fiberglas ladder, which is great except I can’t move it on my own. Another friend loaned me his extension ladder which was moved out to my deck by the drywall guys and will likely remain there until my friend comes to retrieve it — I can’t lift the damn thing. Oh, and for outdoor work, I have a 10-foot orchard ladder I bought two years ago.

Out on the deck, the 5-foot MIA ladder would be perfect — except I don’t have a deck yet and I’m working on 2 x 8 sheets of plywood 10 feet off the ground. It’s scary. I really have to work my way up to doing it. The key is to not look down. I worked on one of the more difficult-to-reach fixtures last week only to discover that the fixture wouldn’t fit in the damn box. After consulting my electrician friend, we decided that the best course of action was to buy a different fixture. That’s on my list of things to do.

In any case, the end of my electrical work is near. I expect to have it all done by this coming weekend. Then on to the next challenge — rails around my loft that are needed to pass inspection for my certificate of occupancy. You can bet I’ll blog about that soon, too.

Discover more from An Eclectic Mind

Subscribe to get the latest posts sent to your email.

Most people think I have no fear of heights, but sometimes, when I climb a tall ladder I get apprehensive!

I don’t like climbing ladders, but I spent most of today on one.

I’ve always found it humorous that since I’m a pilot that I don’t mind heights! Your house is really coming along! You have every reason to feel so proud- you’ve come a long way Maria!

Thanks, Jim!

A quick thought:

Make sure that your room lighting is on a different circuit than your room outlets or appliances.

If something trips a local breaker, you want to have the lights remain on.

It’s a little late for that now, being as all the circuits have been run and wired. But thanks for the advice.

The wiring cart is a great idea.

Thanks! It really is. Actually ANY kind of rolling cart can help you out on a project. I’ve built rolling carts out of discarded wooden crates for use in my shop. Makes it easy to move big bunches of tools — or heavy tools — around. Most recently, I set my miter saw up on one. Very handy.

It’s really interesting to see how much actually goes into electrical work. I’ve been considering doing some of the wiring in my new house, but I’m not very experienced. Your tips helped out quite a bit, especially the part about marking the wires. I’ll have to see if I can get everything installed correctly.