Zero-Mike-Lima moves into its new home.

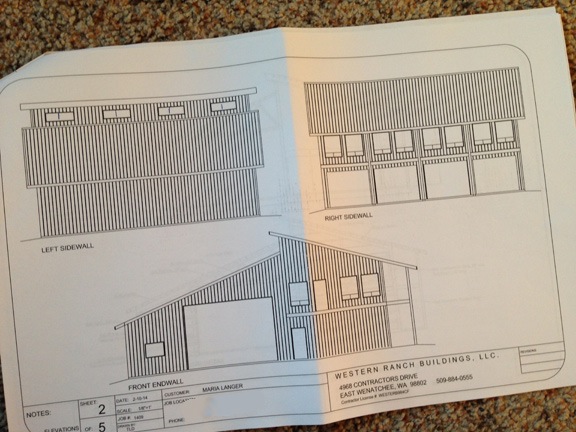

A lot of folks who’ve seen my building plans or listened to me tell them about its design can’t quite understand why I need so much garage space. Like an old motorcycling friend who sadly passed away from an illness some years ago, I’m building a “garage with a home attached.”

Garage, man cave, man trap. Call it what you will, but it has almost 3,000 square feet of garage and shop space.

Moving Forward with the Plan

I decided two and a half years ago, when I started looking for property in Washington, that I wanted to keep my helicopter at home with me. Not only would it be extremely convenient for the few times a month I fly, but it would save me hundreds of dollars a month on hangar costs — not to mention time and truck gas, wear, and tear.

Here’s a partial view of the hangar the helicopter lived in for about eight months. The building was huge and technically I leased only half of it, paying only half rent.

The hangar the helicopter was in last winter, along with my furniture and boxes of possessions from Arizona, was costing $850/month — that’s nearly double my mortgage! I couldn’t wait to get out of that place and was thrilled at the end of June when my building had reached a state of completion where my possessions could be moved into it and I could end the lease on the hangar.

I moved the helicopter to my future home at the end of May, right after the start of cherry season. I had an early contract in Quincy and needed to respond quickly to calls that sometimes came in without warning. From that point forward, it sat outside on a leveled piece of earth in my side (back?) yard — a sort of lawn ornament that I’d fire up when I wanted (or needed) to fly.

I kept the helicopter parked on a nice flat spot near my RV throughout the construction period.

The landing zone was good, despite the dust. I was able to approach from below, actually climbing to reach the spot. This minimized noise. In fact, a few neighbors asked if I were still flying from my home. When I told them I was, they responded, with some surprise, that they never heard me come and go. I’d actually chosen the building location, in part, because of its position between two hills. The idea was to focus the helicopter’s engine sound back out into the valley. A more attractive building location might have been where the helicopter was parked — it certainly would have given me better views. But in the interest of being neighborly — and to reserve that spot for the next property owner’s home — I tucked my building back up against the hillsides.

The building’s shell was finished — walls, roof, floor, doors, and windows — in mid July. The big garage door — 20 feet wide by 14 feet tall — was the last component to be installed. With the help of a friend and his son, I rearranged the furniture I’d stowed in the back of the RV garage space to make room for the helicopter and RV to be parked side by side, as I’d planned.

The Landing Platform

Ground handling a 1500+ pound helicopter by myself had always been a bit of a pain in the ass. It was impossible for me to move it without equipment, so I purchased a tow bar from Brackett Aviation in Kingman and a golf cart to tow it with. I’d had a similar tow bar for my old R22, but the R44 was a bit too beefy for the aluminum model they’d custom made for me (to keep it light). The steel replacement was heavy but manageable. It made it possible to tow the helicopter in Wickenburg from my hangar to the fuel pumps or helicopter pads, despite the hilly ramps.

But what I longed for was a helicopter dolly — a platform I could land on and tow into the hangar. I priced them up everywhere I could find them, new or used, but could never justify the huge expense.

In the winter of 2013, as I packed up my Arizona life and began liquidating possessions I no longer needed, a solution stumbled into my lap. My friend Mike’s friend Jan had bought Mike’s helicopter dolly. Mike had designed it for his Hiller and it had been made to his specifications. He’d used it a few times and, after a scare from a skid sticking to tacky paint in the hot Arizona sun, had sold it to Jan. Jan never used it. I had a very nice golf cart I wanted to unload. Would he take a trade?

He would and did. My friend Janet and I loaded the golf cart onto my flatbed trailer and towed it down to Falcon Field in Mesa. Jan and Mike and a few others drove the golf cart off the trailer and manhandled the dolly, broken down into three pieces, onto my trailer. We strapped everything down and drove back to Wickenburg.

Do I know how to pack a trailer? I replaced the trailer tires and had the bearings repacked before the trip north, just to minimize the likelihood of wheel trouble for my friend on the 1200-mile drive.

Due to the nature of my never-ending divorce, the trailer and dolly just sat in my Wickenburg hangar for months. In September 2013, I loaded a few more things onto the trailer and sent it north on the back of my truck, with a friend who offered to drive it for me while I drove my Honda and movers took everything else. The trailer and dolly then sat in my East Wenatchee hangar for another eight months. In July 2014, it moved from there to my property, where it sat out in the sun for another few months.

Here’s the trailer outside my building last month, waiting to be unloaded. The orange thing is my old tow bar, which I used in my East Wenatchee hangar.

Putting It All Together

What amazed me most is how small the platform looked in my building.

Finally, at the end of September, I asked my friend and his son to stop by and help me unload the dolly. It rolled down the trailer ramp onto the floor of my building. The hard part was pulling the top half off the bottom — I think one more set of muscles might have made that easier. But we did it, lined the pieces up, and bolted them together. The roughly 9 x 9 platform was ready for use. (The flatbed trailer was almost immediately put to work hauling apples to Seattle for a friend. It’s now parked, empty, out of the way behind my building — the only thing I own that’ll likely never be stored inside.)

The only problem was, I couldn’t get the helicopter inside until I had a concrete apron outside the big door. Not only was there a 4-inch drop from the doorway to the ground outside, but the ground was not something the dolly’s 12 hard rubber wheels could easily roll on.

I had the ground work and the concrete work done in September. The concrete guy said I needed to wait five days for the concrete to cure enough to be driven on. Sunday was the fifth day.

I happened to have a charter flight on Sunday and expected to be home by around 3 PM. That morning, before taking off, I positioned the helicopter dolly on my big new pad with my 600cc 1999 Yamaha Grizzly — did I ever mention how glad I am that I bought that thing and brought it to Washington with me? I locked the Grizzly’s brakes and put a wooden block behind one of the dolly’s 12 wheels. (Hard rubber chocks should arrive from Amazon.com today.)

Nothing like a little challenge to get the blood going, no?

Then I got out my extra long measuring tape and started measuring. I measured the helicopter’s skid length and spread. I measured the point from the front of one skid to the end of the front blade. I measured the back of the skids to the end of the tail. I measured the dolly’s width and the distance between the faded and mostly worn off orange painted lines Mike had stuck to years ago. I measured from an arrow on the dolly out the pilot side door to the post in the corner of my future deck.

And then I measured everything again.

And one more time.

It was doable — the measuring tape doesn’t lie — but with the RV parked where it was, I’d best make my approach down the driveway. It was important to come in slowly and not overshoot the platform. If I landed where I should on the platform, everything would be fine.

Yes, it would. I had to tell myself several times. It sure looked close. But then again, every time I land at the fuel island at Wenatchee airport, it’s a lot closer than this.

I shut the big garage door and locked up the building.

The Moment of Truth

I left at 10:30 AM to do my flight. I stopped at Pangborn Airport, fueled up, and met my passengers. We went on a scenic flight up the Methow to view the fire damage, then cut over the mountains to Chelan where we landed in front of Tsillan Cellars Winery. Bob, the owner, walked down with a glass of wine to greet us. My passengers treated me to lunch at the restaurant there before I flew us back to Wenatchee.

Then they were gone and the moment of truth had arrived.

It was right about then that I realized that I’d never landed on this platform before. In fact, the only time I’d ever landed on anything resembling a raised platform was back in 2002 when I landed my old R22 on the back of a trailer.

Well, there’s a first time for everything, huh?

I started up the helicopter — now very light with only about 15 gallons of fuel on board — and headed home. It’s a 3-minute flight.

Instead of approaching from below over my Lookout Point bench, I came in slightly above my landing zone, a bit more to the east. I slowed down to a walking pace before I reached my driveway just behind my shed and chicken coop. Then I moved forward slowly, got myself over the landing pad, and lowered the helicopter down onto it. I had a moment of doubt when I worried that my left skid might be over the gap between the dolly’s two landing platforms and that made me double-think my landing. I wiggled a bit, inched higher, shifted to the left a little, and set it down. The rear of the skids landed first, as they usually do when I’m alone. Then the front. Nice and solid. No movement on the platform.

Success!

Needless to say, I was thrilled.

I went into my RV to let Penny out while the blades slowed to a stop. I took a bunch of photos. I opened the big garage door all the way and locked it in the up position. Then I locked the helicopter’s blades into a front/back position, got on the ATV, started it up, and began rolling it backwards into the building.

The door was supposed to be 14 feet tall. The helicopter’s mast is 10’9″ tall. The platform was 18 inches tall. It should fit, right? Of course it did! But it wasn’t until I actually rolled it in that I believed it.

My landing wasn’t perfect. I could have been forward 6-10 inches and left about 6 inches. When I get a chance, I’ll repaint the surface with better markers. And next time, with the hard rubber chocks handy, I’ll move the platform a bit closer to the edge of the pavement.

The only trouble I had was the fact that my furniture was pushed up against that back wall. With the ATV in front and the helicopter not quite as far forward as it could be, I didn’t have enough room to pull in all the way with the ATV. So I unhooked it, moved it out of the way, and pushed the dolly in the rest of the way. It was remarkably easy to push on the level ground, considering it weighed at least 1800 pounds with the helicopter on it. It was in far enough to close the garage door.

Good thing I didn’t put that arc lamp on a longer chain! It clears the rotor hub by about a foot and a half. In the future, I’ll be parking to one side or another anyway.

A while later, after walking around and taking photos and being thrilled that I could so easily walk under the tailcone to get around the garage even with the helicopter in there, I rolled the door closed and locked it.

My helicopter was in its new home.

On Milestones

This was yet another milestone in my rebooted life — another goal reached without a risk-adverse, fearful, sad-sack old man holding me back. I was moving forward, I was making it happen.

(I feel another divorce-related rant coming on. Stop reading now if you’d prefer not to read it.)

I try not to think about all the years lost waiting for the man I loved to get his act together and take control of his life, to stop being a 9 to 5 slave to possessions he bought for reasons I’ll never understand: a plane he never flew; an expensive, cave-like condo in a dismal city; a luxury sedan not suited for the unpaved road we lived on. I try not to think about what might have possessed him to live beyond his means, year after year.

I try not to think of his broken promises — promises I banked on to build a financially secure future in which we’d both be able to achieve life-long goals.

I try not to think about how hard he tried those last few years to pull me down into the rut he’d dug for himself and how he plied me with guilt and attacked my self-esteem when I resisted.

I try not to think about how miserable I’d be if we’d stuck together and I had to continue a stagnant existence in a dead place with a man who just never seemed to be happy.

But when I see how easily I rebuilt my life here in a better place, how easily I made good friends, how easily I designed and arranged for the building of my dream home, how easily I’ve learned to take care everything that needed to be done — I realize that no matter what he said to put me down, I was not the problem. He was.

I would never be here in this happy place with him holding me back. The divorce freed me to move forward with my life, a life so much better than I had with the sorry excuse for a man that he’d become.

The sad part of it is the way he chose to do this: the deceptions, the betrayals, the legal battle to steal what I’d worked hard for my whole life. The lies in court documents and under oath in court.

He told me two years ago when he asked for a divorce that he wanted to remain friends and I was open to that. But then he did everything in his power to fuck me over emotionally and financially. What’s up with that?

And yes, the battle still rages on, two years after it started. Delays, delays, delays. He’s doing everything in his power to delay my happiness — and he’s failing miserably, at his own expense.

He burned his bridge to any possible future friendship. And in doing so, he threw away the best part of his sorry life.

What an asshole.

As for me — well, I haven’t been this happy in years.