Fixing things and coming up with new storage solutions is a part of RV life.

Because I don’t keep my truck and camper on pavement and because some of the roads I travel on can be pretty rough, my camper is constantly being subjected to considerable bumps and jolts every time I move it. This has a direct impact on some of its components and every once in a while, I need to fix the things that break.

Latches

The most important of these are the latches that keep drawers and cabinets closed. Most of these are spring-action latches that are (unfortunately) made of molded plastic. Over time, these latches — or at least some plastic component within them — cracks and snaps due to the stress of the drawer/door against the rocking motion of the RV as it does down the road. Without latches, the drawers/doors can swing open and closed as I drive, either strewing contents inside the camper or, worse yet, causing stresses on drawer or cabinet structures that lead to wood snapping or other plastic pieces inside failing. The trick is to either get these latches repaired or replaced as soon as possible or tie the drawer or cabinet door closed in such a way that it won’t open in transit.

(The other day, I wrote a blog post about how RVing is preparing me for cruising. In it, I listed a bunch of things that are very similar in the two activities. This is one of them — and I have a good example. When I cruised on Nano earlier this year, one of the drawers would not stay closed when the boat rocked — which it invariably did while we were under way. Capt Paul rigged up a bungee cord to keep the drawer closed. I’m pretty sure he drilled something to make this happen. He also spent the good part of one afternoon fixing other little things around the boat that needed attention.)

The outside (top) and inside (bottom) of the drawer latch I had to replace. There’s another park attached to the cabinet, but that is made of metal and didn’t need replacing.

The problem I faced when I began using my camper this autumn was that the drawer under the stove, which holds heavy pots and pans, would not stay closed. In this case, it wasn’t necessarily the rocking of the camper that broke the latch, although it certainly might have weakened it. I had loaned the camper to one of the pilots who worked for me during cherry season and when he left I just put it away. It wasn’t until I did my first trip down to Pasco for an art show that I discovered the problem.

Although nothing fell out of the drawer in transit, I knew from experience that it would evolve into a larger problem if I didn’t fix it. The contents of the drawer weighed 20 pounds or more — the constant slamming back and forth in transit would break the drawer frame in no time. It had to be fixed.

I tried stacking heavy things in front of the drawer in transit and that didn’t work. Those things just slid elsewhere in the cabin. Then I found a way to jam something into what remained of the latch to hold the catch in place. It was a temporary fix.

The goal was to buy a replacement latch. The problem with that was that my camper is a 2007 and Lance no longer makes that style of latch. Fortunately, I didn’t need to make a newer latch do the job. The Lance dealer in Yakima had two just like the ones I had. I bought them both.

Replacing the latch was an easy enough job that required a screwdriver. I was able to retrieve both of the broken pieces of the old latch. I’ll use epoxy glue to put it back together and then put it with the other spare. I know that more of these latches will eventually break and I want to be prepared.

Light Fixture

My camper has a number of DC-powered light fixtures inside, including two florescent style overhead lights I rarely use. One of them didn’t work quite right — one of the two bulbs was never as bright as the other — and replacing the bulb didn’t help. I was willing to live with that because I didn’t really use those lights. But when the plastic cover over the fixture fell and broke beyond repair, having those ugly florescent style bulbs exposed on my ceiling really bothered me.

So when I was at the dealer getting those latches, I asked about a new fixture. The owner came out and tried a new bulb and got the same results I did. He dug up an old fixture that was the right size — I honestly don’t think it was brand new but it looked new enough — and sold it to me for a reasonable price.

After replacing the latch, I replaced the fixture. It was an involved job that required cutting and rejoining wires. It reminded me of the work I’d done when I wired my home during construction. I still wonder whether I would have tackled this small job if I didn’t have the experience of the big job behind me.

The light fixture looks and works great. But I still seldom use it. I threw the old one away.

Baskets

Every time I break camp and move my camper, I have to stow everything in a place where it’ll stay secure until I park at the next camp. Fortunately, this camper has a ton of interior storage space that’s suitable for large or small items. But what about the items you want to keep handy? Things you don’t want to put away and then take out again every time you stop?

For those things, I installed two baskets which hang on walls. The first is a metal basket that hangs over the door. I use it to store the camper registration, a small pair of binoculars, a pair of small lanterns, spare doggie poop bags, and a handful of other items I might need/want to grab in a hurry on my way out the door. This basket is affixed with two screws that hold it onto the wall.

The first thing that happened was that the screws came loose. They just pulled away from the wall. OK, it’s just crappy drywall and pretty thin. Of course screws wouldn’t be enough on their own. So I got a pair of appropriately sized plastic drywall screw do-dads and re-affixed the shelf with those in place. That fix lasted about two years. Then, the other day, after going down a very bumpy road, I noticed that one of the screws and plastic do-dads had come loose and the other was about to do the same.

I thought about how permanent I wanted this shelf to be. The answer was very permanent. I already had two large screw holes in the wall; if I took the shelf down, I’d have to look at those. So I picked up some epoxy glue at a hardware store and, one afternoon, mixed it up. I used a toothpick to put some in each screw hole. I took everything out of the basket and pushed the two screws with their plastic do-dads back into the holes. I held them in place for the 5 minute set time. Then I let it cure overnight. I was able to put everything back in there before moving on to my next campsite.

The basket hanging over the door. If you look closely, you can see where the epoxy oozed out of the screw holes.

The other basket is in the bathroom. It affixes to the wall with suction cups that you put in place and then twist until they’re secure. Because the bathroom wall is smooth, clean plastic, the basket, which holds shampoos, soaps, and my toothbrush, usually stays in place. For a while. Eventually, it comes down, scattering everything on the floor. I was tired of replacing it.

I thought about gluing the basket into place. Some epoxy on the suction cups would make them stick forever. But then there was the question of permanence. Did I — or the camper’s next owner — really want a basket there forever? Maybe not. (The previous owner had turned the bathroom into a large closet by hanging a metal rod across the whole thing; that was the first thing I’d removed and it required me to patch screw holes in the plastic walls.)

I came up with a solution that I hope continues to work. I bought some 3M adhesive hooks and affixed them to the wall under those suction cups. I then attached the suction cups to the wall as usual. The idea is that the hooks take most of the weight off the suction cups while providing two more attachment points. This would also limit the basket’s motion as the camper sways down the road. With less stress on the suction cups, the basket should stay in place.

That’s the theory, anyway. So far, it’s working. And those stick-on hooks can be removed.

Here’s the bathroom shelf. The screw-to-tighten suction cups hold most of the weight, but the two clear hooks I added below them help, especially in transit.

(Note here that I didn’t buy crappy plastic hooks. I bought 3M, which is well known for the quality of its adhesives. I have (finally) come to realize that it’s often worth a few dollars more to buy the good stuff.)

Shelves

My camper has a deep counter area between the fridge and the table. On brochures, it’s referred to as a “food prep” area. In a camper with very little counter space, it’s nice to have.

But it’s also a waste of space. It’s not terribly wide, but it is deep, going all the way back to the wall. Nothing can be left there in transit — it would definitely slide off the countertop.

In the beginning, I’d put relatively large items in there and use a standard spring-loaded rod to hold the items in place. But it was a messy, disorganized solution that really didn’t take advantage of the height of the space.

So I built shelves out of 3/8 inch sanded plywood. There are 3 shelves in the unit and each shelf has a lip that (theoretically) would prevent items from sliding off the shelf in transit.

There’s a lot going on here. First, you see my shelves with a spring-loaded rod to prevent it from sliding around in transit. Above them, you can see the AC and DC outlets, each with a power port plugged in.

If you watched the video tour of my camper, you can see these shelves in their normal messy state. The idea is to use the top shelf, which is close to both an AC and DC outlet, as a charging station for mobile devices and battery packs. The other two shelves would be used for items that I need to access often but are too small to put loose in a cabinet. The result, as the video clearly shows, is a mess. My latest project was to get that space better organized and to affix the two USB charging outlet units to the shelves so they’re neater and easier to access.

Here’s a closeup look at the two power ports I affixed with zip ties. The vertical one is all USB ports and is DC powered. It’ll work any time. The horizontal one is two standard outlets and three USB ports and is AC powered. It’ll work any time my camper is plugged in to an AC power source, including my generator.

Again, I needed to think about permanence. I also needed to think about attachment points on the actual units. Neither has screw holes and I don’t want to glue them on. My solution was to drill holes in the shelf unit and use zip ties around each unit to hold them in place.

So far, so good.

Other Improvements

I can think of three other improvements I made in the camper since I bought it four or five years ago.

The first was removing the two twin mattresses and replacing them with a queen mattress. Not only is my replacement mattress — one of those hybrids that combine springs with foam and come rolled up in a box — far more comfortable than the crappy RV mattresses that came with it, but who sleeps in a twin bed? It was a huge improvement. Unfortunately, I had to set up the mattress sideways so my pups can easily get in and out of the sleeping area. Still, it works.

The second was adding covered boxes for small clothing storage. Because the camper had two twin beds with a space between them, there was no room in the sleeping area for the cabinets that Lance usually builds into place on either side of the bed. That meant I had no storage for items like socks, underwear, t-shirts, etc. I found fabric covered cardboard boxes with lids in the local Fred Meyer Supermarket on sale for 50% off. I bought enough to fill the space next to the bed. They fit perfectly, are sturdy enough to do the job I need them to do, and they fit all the clothes I don’t want to hang in my closet.

The third was adding hooks. Heavy duty, metal, screw-in hooks. I put them on my bathroom door and on the walls in the sleeping area. They make it possible to keep things like coats, scarves, hats, and those clothing items that are neither dirty nor clean in a place where they’re out of the way yet easy to get to. I also use one of them to hold my laundry hamper in place in transit.

These relatively small improvements were an easy step to making such a small space livable for long periods of time.

My R44, parked out in the desert at a rides event.

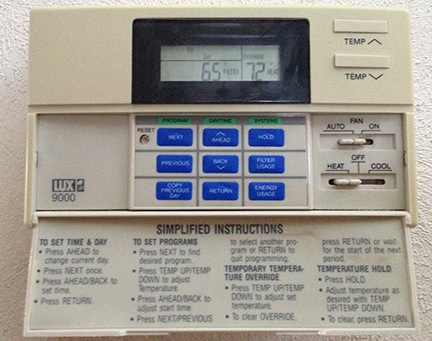

My R44, parked out in the desert at a rides event.