A lot of work with good results…so far.

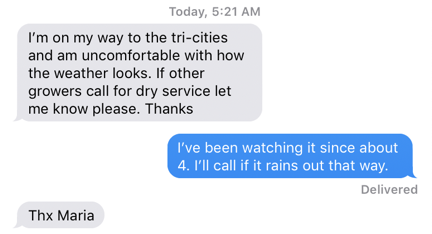

September 2016 Update:This post is very popular every autumn and this year is no different. I responded to some emailed questions with a new blog post that provides additional information on this topic. You can find it here: “Wintering in an RV.”

It was October when I realized that I’d likely need to stay in Washington for the winter. Although I didn’t expect to have much work to do, other business in-state required me to stay for various meetings throughout the winter months.

And then I started getting flying jobs, out of the blue, giving me enough work to make it worth sticking around. I started thinking about enjoying a winter season for the first time in 15 years, of cross-country skiing and snowshoeing with friends. Of really enjoying all four seasons of a year.

Not only was I going to stay, but I was going to make the best of the situation and enjoy my stay.

The No-So-Tough Decision

But where to stay?

I had a few options for winter lodging:

- I could rent a furnished apartment. There are some available in the area, including some that are normally rented out to skiers coming to nearby Mission Ridge. The monthly cost would likely be somewhere between $500 and $1,500 — if I could find one that allowed dogs.

- I could rent an unfurnished apartment. This would likely be cheaper, but it would also require me to move some of my stored furniture to make myself a home. I had to figure in the cost and bother of the move. And again, I needed to find a place that allowed dogs.

- I could “camp out” in my hangar at the airport. The hangar has two offices with baseboard heaters, as well as a full bathroom. My furniture is already there, so it’s just a matter of reorganizing it to meet my needs for the few months I’d need to live there. Unfortunately, I didn’t think my landlord — the folks who manage the airport — would like those arrangements.

- I could live in my RV, either in my hangar — there’s plenty of room — or on my property where it was already parked and hooked up. The trouble with that was that my RV, the “mobile mansion” is not designed for cold weather living. To make matters worse, I had parked it 66 feet from my onsite water source and I knew the hose running in a makeshift conduit under my driveway was very likely to freeze.

Here’s what I saw out my window the other morning, not long after dawn. I look forward to seeing the changing seasons in my view.

In the end, the decision was made easy by the amazing views out my window every day. From my perch high above the Columbia River and Wenatchee Valley, I could enjoy the ever-changing scenery, which varied throughout the day with changes in light and weather. I could watch low-level clouds form and dissipate over the river. I could see the shadows move and lengthen with the shifting of the sun. I would watch the moonlight play upon the hillsides and cliffs. And I could marvel at the lights down in the city, sparkling with color. Would I see all that cooped up in a tiny rental apartment? Or closed up in a cavernous hangar with just three windows? No.

And what of the work I could do on nice days? I was working on a pathway from my RV parking area to my beehives. I’d been planting wildflower seeds and bulbs. And I still hoped to begin construction on my building at the beginning of the new year; I wanted to be around to supervise and document the work.

Besides, since I’d been living in the mobile mansion full-time since the beginning of June, it had become my home, my space. Bought to house two people, a mid-sized dog, and a parrot, it was amazingly comfortable for one person and a tiny dog. After dealing with seemingly countless delays, I’d finally moved it to the piece of land I’d been dreaming about for over a year. I was in my home, on my home. I was loath to give that up, even for a few months.

Of course, to stay in the mobile mansion meant a lot of prep work. I needed to “winterize” it and its water connection to ensure that my water pipes — inside and out — didn’t freeze and that I could keep warm inside. And with frost appearing outside my door on some mornings, I knew I didn’t have much time.

PEX, the Miracle Pipe

The first thing on my list of things to do was replace the standard RV drinking water hose that ran from my city water source across my driveway (in a makeshift conduit I’d created) to the mobile mansion. I needed to run some kind of water line that I could run heat tape along. Heat tape (or trace heating) uses electricity to apply a small amount of heat to pipes to prevent freezing. I had some experience with it from my Howard Mesa cabin, where we’d used it on a very short length of hose between a water tank and the building. But rather than a 6-foot length of the stuff, I’d need 66 feet of it. That meant two 30-foot lengths plus one 6-foot length.

Regular hose, however, was not recommended by the heat tape manufacturer, which clearly specified metal or plastic water pipe. A hose was not a water pipe. Perhaps it wouldn’t work as well. Or perhaps it would degrade the hose and cause problems. I could imagine being poisoned by the breakdown of chemicals in my hose. (Seriously: I have a pretty good imagination sometimes.)

Enter PEX. My friend Mike, who’d done most of the interior work on his home in Wenatchee Heights, had raved about it. I did some research. PEX was more costly than PVC but less costly than copper. It didn’t require any welding — or whatever it is that people do to copper pipes to join them — and it was flexible. There were two kinds of fittings. One kind required special (costly) crimping tools. The other kind, known as PTC, let you literally snap pieces together, with no special tools at all. All I needed was a PVC pipe cutter (which I already had) and a very inexpensive tool I could use to separate joined pieces if I made a mistake. The snap fittings were a bit more costly than the crimp type, but I only needed a few. I bought a 100-foot roll of blue 3/4 inch PEX.

A typical PTC to female pipe fitting.

I also bought PTC fittings. I needed one to join the PEX to a male hose connection and another to join the PEX to a female hose connection. I had a tiny bit of trouble with that — PEX connections normally work with pipe threading, not hose threading. (The fact that the two threadings are different is something I learned back when I set up the irrigation system at my Wickenburg house years ago.) The Home Depot pipe guy helped me get what I needed.

But there was one more thing I needed: pipe insulation. I wanted to wrap the pipe with the heat tape on it to help keep it warm. I checked out my options and decided on an adhesive wrap. Although it came in 15-foot lengths, I wound up needing 7 rolls of it because it had to go around the pipe. (This, by the way, is also when I learned that when you buy stuff for a home project at a place like Home Depot, always buy more than you think you need. It really sucks to run out of something in the middle of a project and you can always return unused items later. Home Depot has an excellent return policy.)

I went back and got to work. The biggest chore was attaching the heat tape to the pipe and insulating it. The big challenge there was straightening the PEX. It does straighten, but it straightens easier when it’s warm and it does require muscle. (Needless to say, I was sore the next day.) I cut off about 70 feet of the stuff and ran it across my driveway from the water source to my RV’s water connection area. Then, with the sun shining full on me the next morning, I brought out a clean damp rag (to clean away dust on the PEX as I worked), set up a chair, and got to work.

You see, because the PEX was so long and relatively inflexible, I had to move along the length of the PEX to get the job done. I couldn’t stay in one place and move the PEX. Adding the heat tape and insulation also made the PEX heavier, so moving it later would not be a good option. That was okay.

I was very pleased with my choice of insulation. Normally, I’d have to tape the heat tape to the PEX every six inches with a piece of electric tape. (Heat tape is not adhesive, despite its name.) But the insulation tape was adhesive so I just used it to stick the heat tape to the PEX, wrapping it as I went along.

It took a long time. Three days of about four hours a day with a few breaks for phone calls, snacks, and to track down a tiny dog who thinks she can chase bighorn sheep up on the cliffs. But finally, I was done. One end had two cords (one for the 30-foot length and one for the 6-foot length) and the other end had one cord (for the other 30-foot length).

I attached the fitting on the RV end of the PEX. I could not believe how easily it snapped into place. Working with this stuff on my new home was going to be a breeze. I trimmed the water source end and attached the fittings there. So far, so good.

Finishing Up the Water Pipe

Of course, I couldn’t have the wrapped tape stretched out in the elements across my driveway, especially when the snow started falling. So I got out my shovel and I dug another trench just deep enough to lay a conduit that I could seal the wrapped PEX into to keep it dry and enable me to drive over it.

For the conduit, I used brown vinyl downspout pipe. That’s the stuff people usually use to go from the gutter on the edge of the roof to the ground. I bought six 12-foot lengths of the stuff and six connectors. I also bought a pair of matching flex elbows to use at either end. I ran the PEX in this pipe, making connections as I went along. Then I laid it in the trench, put the flex pipes on both ends, and connected the ends of the PEX to the water source and RV. When I was finished, the PEX was completely enclosed in the pipe.

I crossed my fingers as I turned on the water. This was the moment of truth. If any of my connections leaked, I’d have a bunch of disassembling to do to find and fix the problem.

Imagine my pleasant surprise when not a single drop of water leaked from either end of the PEX! I love this stuff!

I had a few more things to do:

- I needed to insulate the water source pipe and any portion of the pipe that wasn’t covered with heat tape or adhesive insulation. I used regular foam pipe insulation for that.

- I needed to cover the water source area with waterproof material to prevent water from getting into the flex elbows. I used a heavy duty plastic garbage bag with bungee balls to keep it in place.

- I needed to cover the trench across my driveway. I shoveled the dirt back in and placed construction cones at either end where the pipe emerged from the ground.

- I needed to plug in the heat tape. I plugged two of the three cords in at my power pole and ran an extension cord across the driveway for the third plug. (I didn’t want the heat tape using the same circuit as the RV for various reasons.)

Then I was done.

Testing the Water Setup

Just in time!

The next morning was cold. I turned on the faucet and nothing came out.

I turned on the RV’s water pump. My internal tanks were full and functioned fine. But I had to troubleshoot the problem with the new pipe.

It turned out to be pretty simple: the heat tape was plugged into a socket that had tripped its GFCI. I reset the GFCI and tested the outlet. It worked.

Of course, it didn’t get cold again for quite a while. Three weeks, in fact. This morning, the temperatures dropped down in to the 20s. I turned on the water and it flowed.

All that work — and the approximately $150 I’d spent on parts — had paid off.

Basement Pipes

The mobile mansion has what I call a basement. It’s a huge storage area in the front under the bathroom and part of the bedroom. Most of the pipes that supply water to the bathroom fixtures run exposed in the basement ceiling.

The basement is not heated. When temperatures in the basement dropped down to freezing, the pipes could freeze, too.

My first thought was to insulate them with regular foam pipe insulation. I even got started doing that. But then I realized that a better solution would be to simply put a space heater in the basement and make sure it ran when it was cold out.

The trouble was, the basement was full of stuff. I’d have to move all the stuff out. I couldn’t fit all the stuff inside the mobile mansion. That meant having to store it in my hangar with the rest of my things.

I was bummed. There was some stuff there that I wanted to keep handy. Still, protecting the pipes was more important than convenience so I resigned myself to moving it all out.

Every morning, Penny lounges by the radiator in the living room.

That’s when I happened upon a gently used 6 x 8 shed for sale at an amazing price. I moved almost everything in the basement into the shed. Storage problem solved. The basement was now empty enough to put in a heater and not have to worry about things catching on fire.

Inside the RV, I had been using one of those oil-filled radiator style electric heaters for years. I kept it in the living room. In the bedroom, I had a small tabletop electric heater with a fan to push the warm air. Trouble was, I don’t like listening to a fan while I sleep so I never used it at night.

The radiator heaters are silent. I bought a second one, which had a fancy thermostat, and put the original in the bedroom. That freed up the little tabletop heater for basement duty and ensured a warm, quiet sleeping environment.

I placed it in the middle of the basement floor. Then I connected it to a temperature-sensitive outlet called a Thermocube at the end of the extension cord I was already using for the heat tape. The Thermocube supplies power to its outlets when temperatures dip to 35°F and turns off power when temperatures rise to 45°F. I turned the heater on to the lower of its two settings, figuring that would be enough to keep the area from freezing.

In this shot you can see the basement insulation panel as well as the connection for the water into the RV. The orange wire is for the heat tape; the red is the extension cord. Both are run into the basement where the heater is also plugged in. The blue coiled hose is the RV’s “outdoor shower” which I can’t seem to disconnect so I left it there.

Of course, like the rest of the RV, the basement isn’t very well insulated, either. Fortunately, I had four foam insulation panels I’d bought for another purpose. I did some trimming and made two insulation panels for just inside each basement door. Although it wasn’t a perfect solution for insulating the space, it was better than nothing.

Over the next few weeks, I’d open the basement doors to check the temperature in there. Although I never saw the heater on, it was always considerably warmer in that space than outside. I assumed the heater was getting the job done.

The Straw Skirt

The reason I had the foam insulation panels in the first place was because I had a crazy idea about possibly using them to build a skirt around the base of the RV. Many people had advised closing this space off to help keep the RV warm. But the mobile mansion is about 35 feet long. Foam was neither practical nor cost-effective.

I consulted with several friends. My friend Bob sketched out a frame that I could build with 2x4s and plywood. It would take a lot of wood and a lot of work. He gave me some wood for the frame to get me started.

But then my friend Tom, who lives in Vermont, suggest straw bales. I felt like slapping myself on the side of the head. Like duh. Not only were they good for insulation, but I’d be able to use them in the spring in my garden.

My first load of straw bales in the back of my truck.

So I went to get straw bales. I started with six. They loaded them in the back of my truck. It reminded me of the old days, when I’d get hay for my horses. I even bought a hay hook to make it easier to move them around.

I backed the truck up near the mobile mansion. The guy who loaded them told me they weighed around 80 pounds each. I don’t think they were that heavy. After all, I was able to get them into position easily by myself. They made a nice thick skirt against the sides of the RV.

The first six bales of straw in position around the mobile mansion. It took 22 bales to get the job done.

But six wasn’t nearly enough. I went back later in the day and bought another eight. This time, the loader put a palette in the back of the truck. It just fit. I strapped the straw down to prevent it from tipping off and brought them home. When I finished moving them around, I realized that another eight bales should do the job.

I got them two days later and put them in place. Although it wasn’t perfect, it was better than nothing. I’d fiddle with them and with spare pieces of wood and cardboard throughout the coming weeks.

Total cost of the straw skirt: around $200. Time and effort: minimal.

About the Physical Activity

I want to take a moment to comment about the physical activity needed to get all this work done.

First was dealing with the coiled PEX. I really needed to put some muscle into it to straighten it out. And that needed to be done about 3 feet at a time.

Next was digging the trench across my driveway. Although I’m fortunate that there are very few rocks in my primary building site — which also made the septic system guy pretty happy — the driveway did have a layer of gravel over it. I had to dig through that gravel and into the softer dirt beneath it. Later, I had to shovel all that gravel back. Hard work!

Finally, I had to deal with moving 22 straw bales from the back of my pickup into position all around the RV. I don’t really know what they weighed, but they were pretty heavy. I did a lot of dragging, mostly because I couldn’t do much lifting.

The days after doing each of these things, I really felt it in my muscles: shoulders, arms, abdomen, etc. But the soreness felt good. I can’t really explain what I mean by that. I think it has something to do with finally being back in shape after so many years of living in limbo. I’d let myself go physically (and mentally) while my future was delayed, waiting for a partner to fulfill promises he never meant to keep. Losing weight last year, getting back into outdoor activities, feeling good about myself again — that’s only part of my reward. The other part is the ability to do hard work again, to get a job done without waiting for someone to do it for me. (Not to mention the ability to make decisions without having to debate them with someone who seems to prefer arguing over getting things done.) The aches and pains were a reminder of how good independence really is and how great it feels to be physically fit and healthy. I love it!

The End Result

Last night, the temperatures dipped into the 20s. I know because I bought a thermometer with three wireless sensors — the one I fastened at my water source read 22°F this morning. In the basement, the temperature stayed in the high 30s. When I turned on my taps, the water flowed.

Inside, the RV is cool but not cold. Both radiators are on, although the one in the bedroom is set to low. I have an electric blanket on my bed so I’m never cold at night. The RV’s gas heater with its loud fan supplements the heat in the living room in the morning. I know I could keep it warmer if I’d just close the blinds, but I’d rather put on a sweater than miss out on the views outside my windows.

It’s unseasonably cold this week so I’ll have a good chance to test my setup. I’m not too concerned. The other day, one of my neighbors, who is going away for the winter, kindly offered me his home. I’ll talk to him later today; that might make a Plan B for nights that are just too cold to stick around. But it shouldn’t get much colder than it is this week, so there’s a good chance I’ll be living in my own space all winter long.

We’ll see. I’ve done my part; let’s see what Mother Nature challenges me with.