It’s like getting silver sheet for 1/3 off the price.

I use a lot of silver when I make jewelry: fine (100%) silver, sterling (92.5%) silver, and Argentium (93.5%) silver. Although I used to work primarily with silver wire, I’ve begun doing more with sheets of silver. I generally use 22 gauge sheet to make pendants and 26 gauge to make earrings.

The Cost of Metal

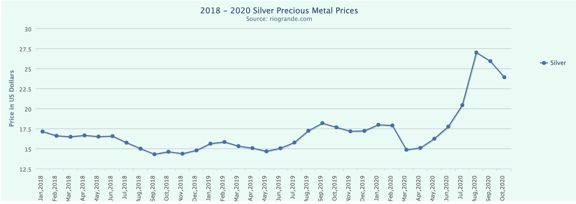

As I type this, I can buy 22 gauge sterling silver sheet for $4.36 per square inch. That price varies wildly — just a few months ago it was about 30% less. More recently, it was about 10% more. You can track precious metal prices online in a bunch of places, but I track it on the Rio Grande website, since that’s where I buy my metals.

Here’s a chart of the silver prices, which went nuts back in June 2020. It looks like it’s settling down now. You can track metal prices at the Rio Grande website.

The price I pay is a combination of market price (as shown in the graph above) and the type of processing applied to the metal. Sheet metal will cost more per ounce than just plain old lumps of silver. After all, the folks doing the processing have to get paid for their work, no? That’s value added pricing.

The Value of Scrap

Rio Grande has a scrap metal program that will take my scrap silver and pay me 85% of market value for it. So if I send them an ounce of fine silver and the current market price is $24/ounce, they’ll pay me $20.40/ounce. The values are different, of course, for sterling and Argentium. They do gold and platinum, too, but I don’t use much gold or any platinum in my work (yet) because of the crazy high price.

I’ve taken advantage of the recycling program at least twice. I save every single scrap of silver and try hard to keep the fine silver separate from the alloys. When in doubt about a scrap, I throw it in with the alloys. The first time, I got about $50 back. The second time I had more scrap and got over $100 back. I take it as a credit on my account because I generally spend well over $1,000 on metals every year anyway.

Recycling My Own Scrap

Ok, here’s something you don’t see (or hear) every day. I’ve just prepared this small crucible for melting scrap silver by melting borax in it to create a glasslike surface. It’s about 800F here and cooling. Volume all the way up; listen carefully. pic.twitter.com/RT7Eq8bMEc

— Maria Langer (@mlanger) August 22, 2020

The first step was to prep the crucible. I posted this video on Twitter to share the sound of the cooling crucible.

Recently, however, I watched a few “YouTube University” videos that showed jewelers making their own wire and sheet from scrap. To do this, I’d need a good, hot torch (which I already had), a small crucible, a mold, and some borax (which I already had). I decided to give it a try. Invested about $40 in the equipment I didn’t have and started melting silver.

My second try at an ingot.

It wasn’t as easy as it looked in the video — what else is new, right? — but I did manage to get a decent little ingot on my second try. (I melted down the first try so no loss.)

The backing for this malachite cabochon was made with silver I recycled.

I rolled it through my rolling mill, periodically annealing it to soften it back up, and got it down to a sheet roughly between 21 and 22 gauge. I textured the resulting piece, then cut out a shape for a backing plate for a cabochon pendant. I added prongs and a hole for a bail, cleaned and polished the piece, and set the stone. It looked great (if I do say so myself).

The interesting thing about my recycled silver is that it’s a higher percentage of fine silver than Sterling (92.5%), but not nearly as high as fine silver (100%). Because it also contains some Argentium (93.5%), it might have some of the tarnish resistance properties of that alloy. Legally, I can stamp it 925 because that’s the minimum purity of the piece.

Doing the Math

Yesterday, I made two more ingots. It took quite a while because I was aiming for larger ingots and, for the second one, was trying to melt larger pieces of scrap. I actually had to stop and refill my torch to get the job done.

Here are the two ingots I made yesterday. They weigh at least an ounce each. The darker one has been through the rolling mill about 20 times and is dark because it’s freshly annealed in this photo. The larger ingot has not been rolled at all yet.

I started wondering whether it was really worth the effort. So this morning, I did the math.

Suppose I want 22 gauge sterling silver sheet. I looked up the price on Rio Grande, where I would buy it, and came up with the number $4.36/square inch or $31.14/ounce. (Remember the added value of turning silver into sheet.)

Now let’s look at how much I’d get back from Rio if I recycled an ounce of silver. With a current market price of $24/ounce and a rate of 85%, I’d get $20.40/ounce. Because a square inch of 22 gauge silver weighs .14 ounces, the refund would equate to $2.86/square inch.

In summary:

| Description | per sq in | per oz |

| Cost of of 22 gauge silver bought new | $4.36 | $31.14 |

| Value of equivalent amount of recycled silver | $2.86 | $20.40 |

| Amount I save by recycling my own silver | $1.50 | $10.74 |

Of course, it’s even more cost effective to recycle my own silver now that Rio Grande has instituted a $50 recycling fee (beginning October 15, 2020). This makes it completely impractical to send my silver back to them — I’d never have enough silver to make this worthwhile. In hindsight, it’s a good thing that I learned how to make ingots before this fee came into effect. I’m ready for it.

Being ready for the change in the processing fee was good timing Maria. How do you check the percentage of silver in your recycled ingots? I assume you can’t be certain of the segregation of the fine silver and alloy.

I can’t check it. But logically, I can guess. If the minimum percentage of silver I use is 92.5% (sterling) and I’m adding some unknown quantity of 93.5% (Argentium) and 100% (pure), the minimum percentage of the result is 92.5%. So that’s what I’ll go with: sterling. I think of it as “Sterling Plus” but can’t market it that way.

I try to segregate pure and Argentium scrap, but when I work on a mixed metal project or do wire work away from my shop, I don’t always distinguish. The mix goes into the sterling bin. I never use any silver less than 92.5%.

If I melt down the pure silver scrap, I’ll have pure silver. If I melt down the argentium scrap, I’ll have Argentium. Right now, I don’t have enough of either one to make a decent sized ingot.